Process of extracting volatile oils and alpinetin from Alpinia katsumadai

A technology of volatile oil and alpinol, which is applied in the field of extracting volatile oil and alpinol, can solve the problems of high extraction loss of effective parts, low extraction rate, and increased activity of pepsin, and achieve the goals of reducing purification steps, easy operation, and reduced dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

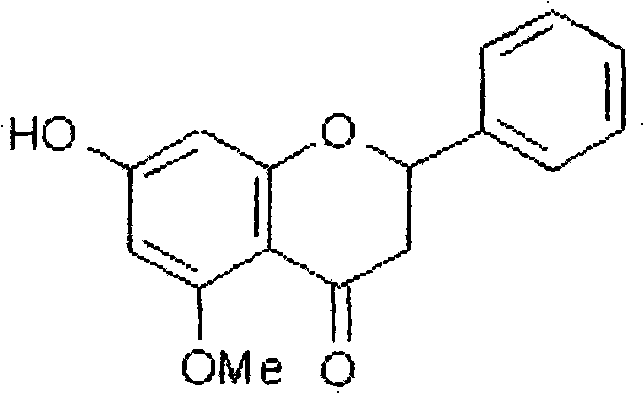

Image

Examples

Embodiment 1

[0024] Remove impurities from the cardamom medicinal material, crush it into a coarse powder, take 500g and put it into the extraction kettle, debug the extraction kettle, the extraction temperature is 45°C, the extraction pressure is 18MPa, CO 2 The flow rate is 40L / h, the extraction time is 1.5h, the temperature of the separation tank I is 40°C, the pressure is 6.5MPa, the temperature of the separation tank II is 45°C, and the pressure is 5.5MPa, the extract is analyzed from the separation tank, and the extract is collected. Filter to obtain the volatile oil product, add the above extracted medicinal residues to 0.1L 85% methanol solution, and adjust the extraction parameters: the extraction temperature is 55°C, the extraction pressure is 45MPa, CO 2 The flow rate is 35L / h, the extraction time is 2.5h, the temperature of the separation tank I is 40°C, the pressure is 9MPa, the temperature of the separation tank II is 45°C, the pressure is 6.5Mpa, and the supercritical CO 2 E...

Embodiment 2

[0026] Remove impurities from the cardamom medicinal material, crush it into a coarse powder, take 500g and put it into the extraction kettle, debug the extraction kettle, the extraction temperature is 35°C, the extraction pressure is 25MPa, CO 2 The flow rate is 30L / h, the extraction time is 3h, the temperature of the separation tank I is 30°C, the pressure is 7MPa, the temperature of the separation tank II is 35°C, and the pressure is 6MPa, analyze the extract from the separation tank, collect the extract, and filter to obtain For volatile oil products, add the extracted medicinal residues to 0.1L 90% methanol solution, and adjust the extraction parameters: extraction temperature is 75°C, extraction pressure is 30MPa, CO 2 The flow rate is 25L / h, the extraction time is 5h, the temperature of the separation tank I is 45°C, the pressure is 10MPa, the temperature of the separation tank II is 40°C, the pressure is 5.5Mpa, and the supercritical CO 2 Extraction, collect flavonoids...

Embodiment 3

[0028] Remove impurities from the cardamom medicinal material, crush it into a coarse powder, take 1kg and put it into the extraction kettle, debug the extraction kettle, the extraction temperature is 40°C, the extraction pressure is 20MPa, CO 2 The flow rate is 25L / h, the extraction time is 2.5h, the temperature of the separation tank I is 35°C, and the pressure is 6MPa, the temperature of the separation tank II is 30°C, and the pressure is 5MPa. Analyze the extract from the separation tank, collect the extract, and filter it. To obtain the volatile oil product, add the above-mentioned medicinal residue after extraction to 0.2L95% methanol solution, and adjust the extraction parameters: the extraction temperature is 65°C, the extraction pressure is 35MPa, CO 2 The flow rate is 45L / h, the extraction time is 2h, the temperature of the separation tank I is 40-45 ° C, the pressure is 7 MPa, the temperature of the separation tank II is 35 ° C, the pressure is 5 MPa, and the supercr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com