Water-based inorganic zinc shop primer, its preparation method and its application

A shop primer and inorganic zinc technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve problems such as low viscosity, inability to meet the requirements of shop primer film thickness, gun blocking, etc., and achieve excellent The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

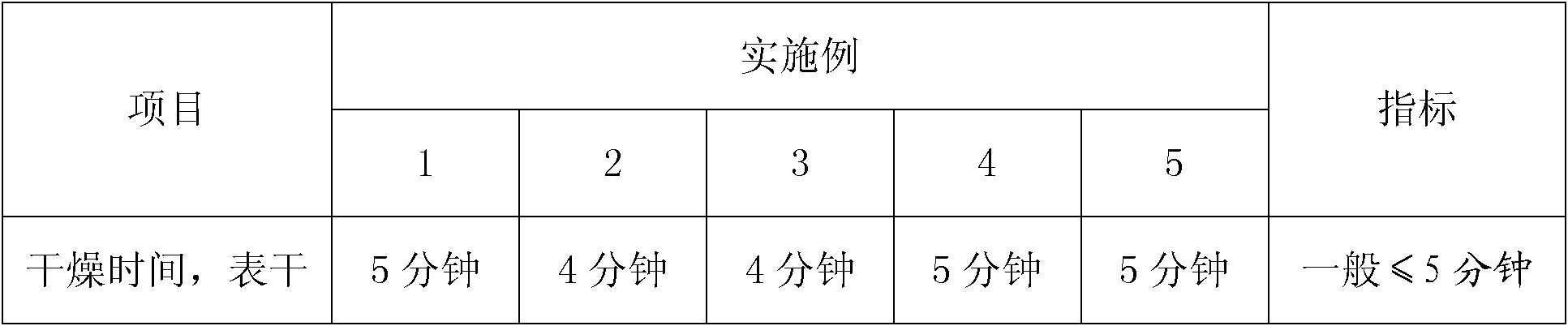

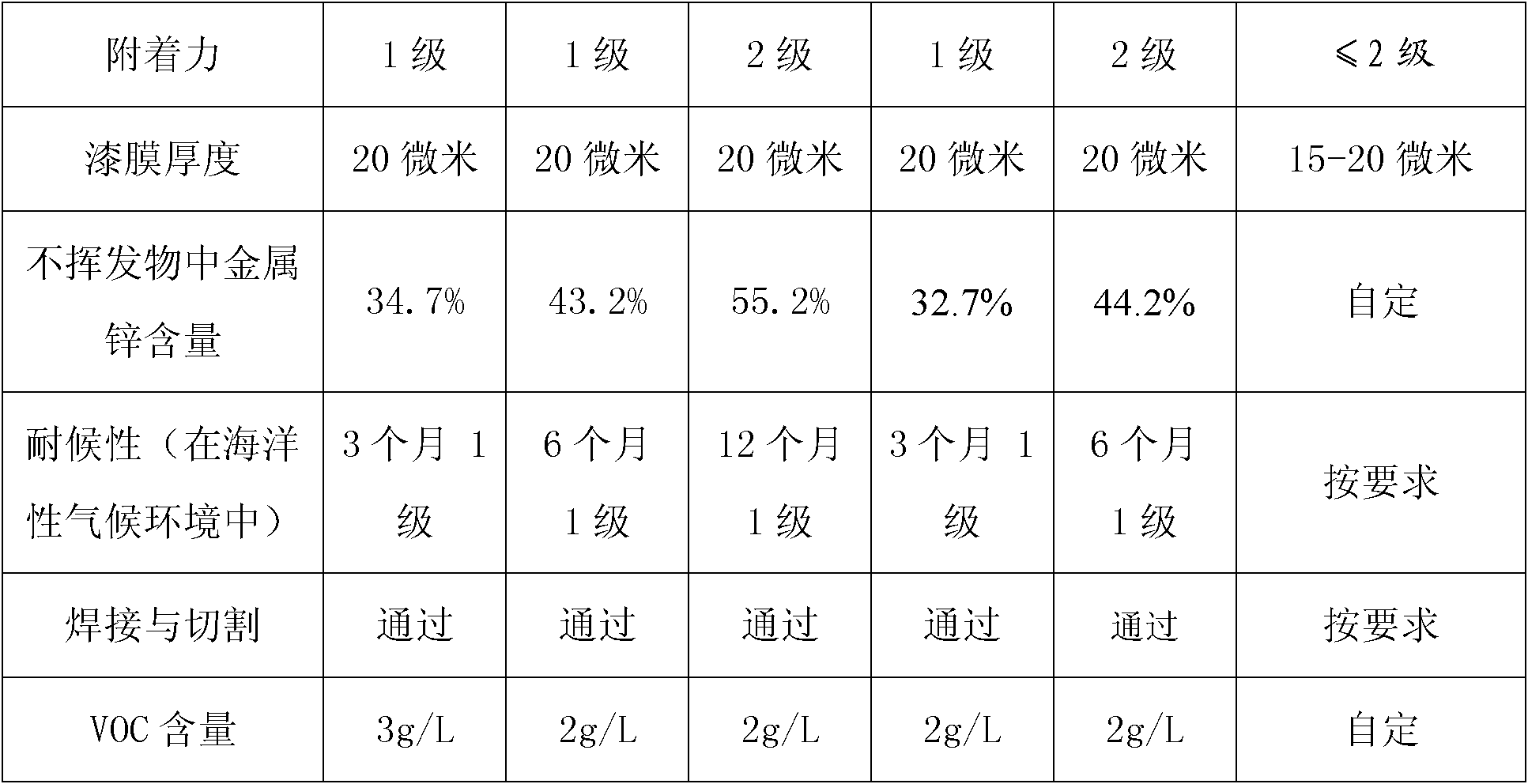

Examples

Embodiment 1

[0067] Embodiment 1 3 months anticorrosion shop primer

[0068] The formula of base material is as follows:

[0069] Spherical zinc powder (particle size is 2-5 microns) 124 kg

[0070] Flake zinc powder (long diameter 15-20 microns) 16 kg

[0071] Silica 5 kg

[0073] Titanium dioxide 50 kg

[0074] 200 kg of water

[0076] 3 kg imidazoline quaternary ammonium salt

[0077] Surfactant RHODAPON BOS 1 kg (Rhodia Corporation)

[0078] Anti-sedimentation agent ST-1 1.2 kg (Shangtianti Fengsen Bentonite Factory, Xinyang City, Henan Province)

[0079] Defoamer BYK-017 0.5 kg (Bick company)

[0080] The formula of curing agent is as follows:

[0081] Lithium silicate: 600 kg

[0082] Acrylic monomer: 10 kg

[0083] Styrene: 40 kg

[0084] Methyl acrylate: 20 kg

[0085] Ethyl acrylate: 20 kg

[0086] Defoamer BYK-017 1 kg (Bick company)

[0087] Dispersant E-1302 10 kg (Jiangsu Haian Petrochemical Co., Ltd.) ...

Embodiment 2

[0092] Example 2 Six-month anti-corrosion water-based shop primer

[0093] The formula of base material is as follows:

[0094] Bentonite 12kg

[0095] Spherical zinc powder (particle size is 2-5 microns) 456 kg

[0096] Flake zinc powder (long diameter 15-20 microns) 144 kg

[0098] Magnesium silicate 115 kg

[0099] Ferrophosphorus powder 124 kg

[0100] 400 kg of water

[0102] MBTS (3 methyl thiophene) 4.5 kg

[0103] Surfactant RHODAPON PEH 1 kg (Rhodia Corporation)

[0104] Anti-sedimentation agent ST-3 2 kg (Shangtian Tifengsen Bentonite Factory, Xinyang City, Henan Province)

[0105] Defoamer BYK-019 0.7 kg (Bick company)

[0106] The formula of curing agent is as follows:

[0107] Sodium silicate 600 kg

[0108] Styrene 40 kg

[0109] Methyl acrylate 20kg

[0110] Ethyl acrylate 20 kg

[0111] 280 kg of water

[0112] Dispersant E-1308 10 kg (Jiangsu Haian Petrochemical Co., Ltd.)

[0113] De...

Embodiment 3

[0117] Embodiment 3 12 months anticorrosion water-based shop primer

[0118] The formula of base material is as follows:

[0119] Bentonite 10kg

[0120] Silica 15 kg

[0121] Spherical zinc powder (particle size is 2-5 microns) 540 kg

[0122] Flake zinc powder (long diameter 15-20 microns) 40 kg

[0123] Phosphorus powder 50 kg

[0124] 170 kg of water

[0125] Bismuth oxide 2 kg

[0126] DMTD 5kg

[0127] Heavy calcium 207 kg

[0128] Surfactant RHODAPON BOS 1 kg (Rhodia Corporation)

[0129] Anti-sedimentation agent ST-4 2.5 kg (Shangtianti Fengsen Bentonite Clay Factory, Xinyang City, Henan Province)

[0130] Defoamer BYK-019 0.8 kg (Bick company)

[0131] The formula of curing agent is as follows:

[0132] Potassium silicate 600 kg

[0133] Acrylic monomer: 20 kg

[0134] Styrene 40 kg

[0135] Methyl acrylate 20kg

[0136] Ethyl acrylate 20 kg

[0137] Water 310 kg

[0138] Dispersant E-1306 10 kg (Jiangsu Haian Petrochemical Co., Ltd.)

[0139] Defoam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com