Magnesium alloy support coated with acylated chitosan and polyester blend medicine coating

A technology of acylating chitosan and magnesium alloy stents, which is applied in the field of biodegradable vascular stents, can solve the problems of accelerating the initial degradation rate of magnesium alloy substrates, showing acidity, etc., and achieves good collateral passage, intracellular inflammatory response, The effect of unobstructed blood perfusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

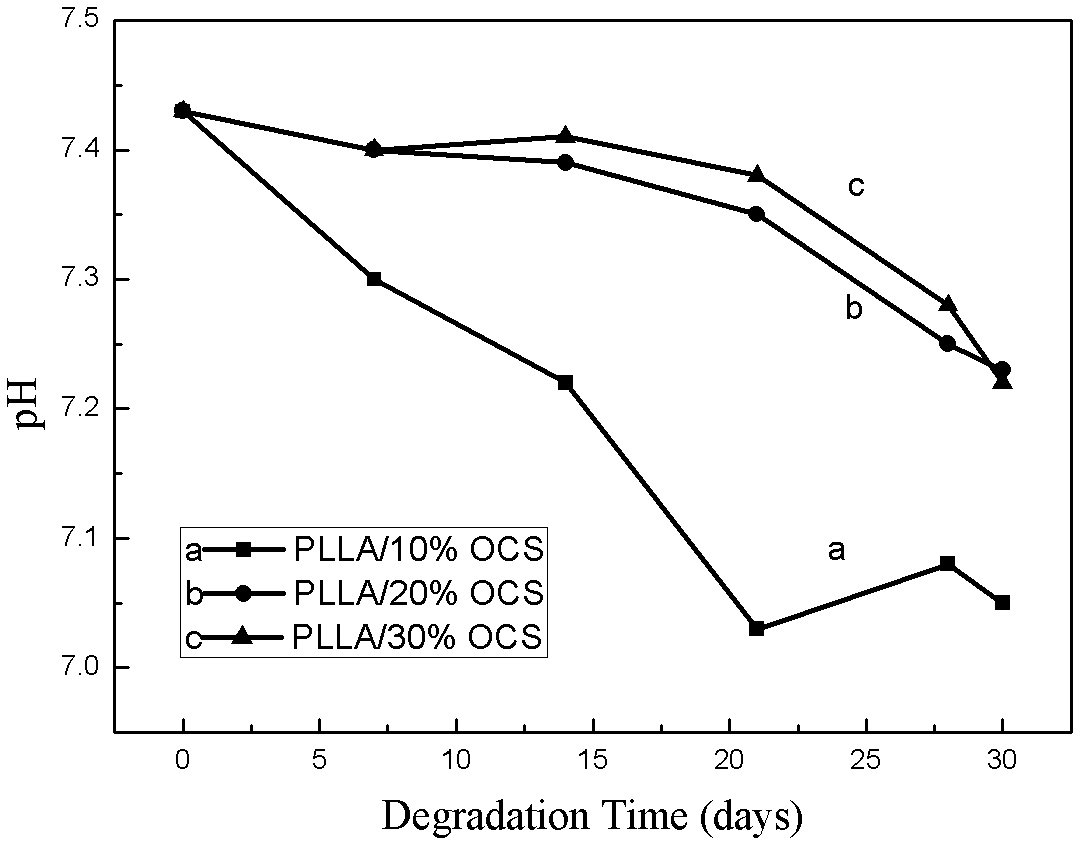

[0026] Specific embodiment one: first in methanesulfonic acid medium, lauryl chloride and chitosan unit (molecular weight is 200000) are reacted with molar ratio as the ratio of 5: 1 to prepare acylated chitosan OCS, according to PLLA / OCS =30% ratio Dissolve the two blending components in an organic solvent to prepare a homogeneous polymer solution. According to the ratio of drug: polymer drug-loaded material = 10% to 30%, the drug is added to the polymer solution, and a certain volume of organic solvent is added to prepare a uniform coating solution with a certain concentration. Finally, a single-layer drug coating is prepared by ultrasonic atomization and spraying. The drug is one or a combination of drugs with anti-restenosis function including paclitaxel, rapamycin, dactinomycin, emodin, etc. The process parameters to obtain the best coating solution atomization effect are: the solution concentration is 1%, the power of the ultrasonic generator is 0.8, the injection speed...

specific Embodiment approach 2

[0030] Specific embodiment two: experimental condition and operation process are identical with specific embodiment one, just change in the acylated chitosan preparation process, lauryl chloride and chitosan unit (molecular weight is 200000) are the ratio of 5: 1 with molar ratio The reaction is carried out, the two blending components are dissolved in an organic solvent according to the ratio of PLLA / OCS=20%, and finally a single-layer drug coating is prepared by an ultrasonic atomization spraying method. Finally, the drug-eluting stent coating of acylated chitosan-polyester blend was characterized. The experimental results show that the hemolysis rate is 2.17%, but all values are less than the critical value of 5%, indicating that these materials do not produce obvious hemolysis when they come into contact with blood, and all meet the requirements of the hemolysis rate of biological materials. When the time reaches 60 minutes, the OD value is about 0.31, which is still gre...

specific Embodiment approach 3

[0031] Specific embodiment three: experimental condition and operation process are identical with specific embodiment one, just change in the preparation process of acylated chitosan, lauryl chloride and chitosan unit (molecular weight is 200000) are the ratio of 5: 1 with molar ratio The reaction is carried out, the two blending components are dissolved in an organic solvent according to the ratio of PLLA / OCS=10%, and finally a single-layer drug coating is prepared by an ultrasonic atomization spraying method. Finally, the drug-eluting stent coating of acylated chitosan-polyester blend was characterized. The experimental results show that the hemolysis rate is 2.46%, but all the values are less than the critical value of 5%, indicating that these materials do not produce obvious hemolysis when they come into contact with blood, and all meet the requirements for the hemolysis rate of biological materials. When the time reaches 60 minutes, the OD value is about 0.32, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com