Temperable three-silver low radiation coated glass and production technology thereof

A low-emission coating, glass technology, applied in glass/slag layered products, layered products, metal layered products, etc., can solve the problems of appearance color interference, limited color selection, low visible light transmission, etc. Reduce the influence of the uniformity of the film layer, the effect of uniform film formation and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

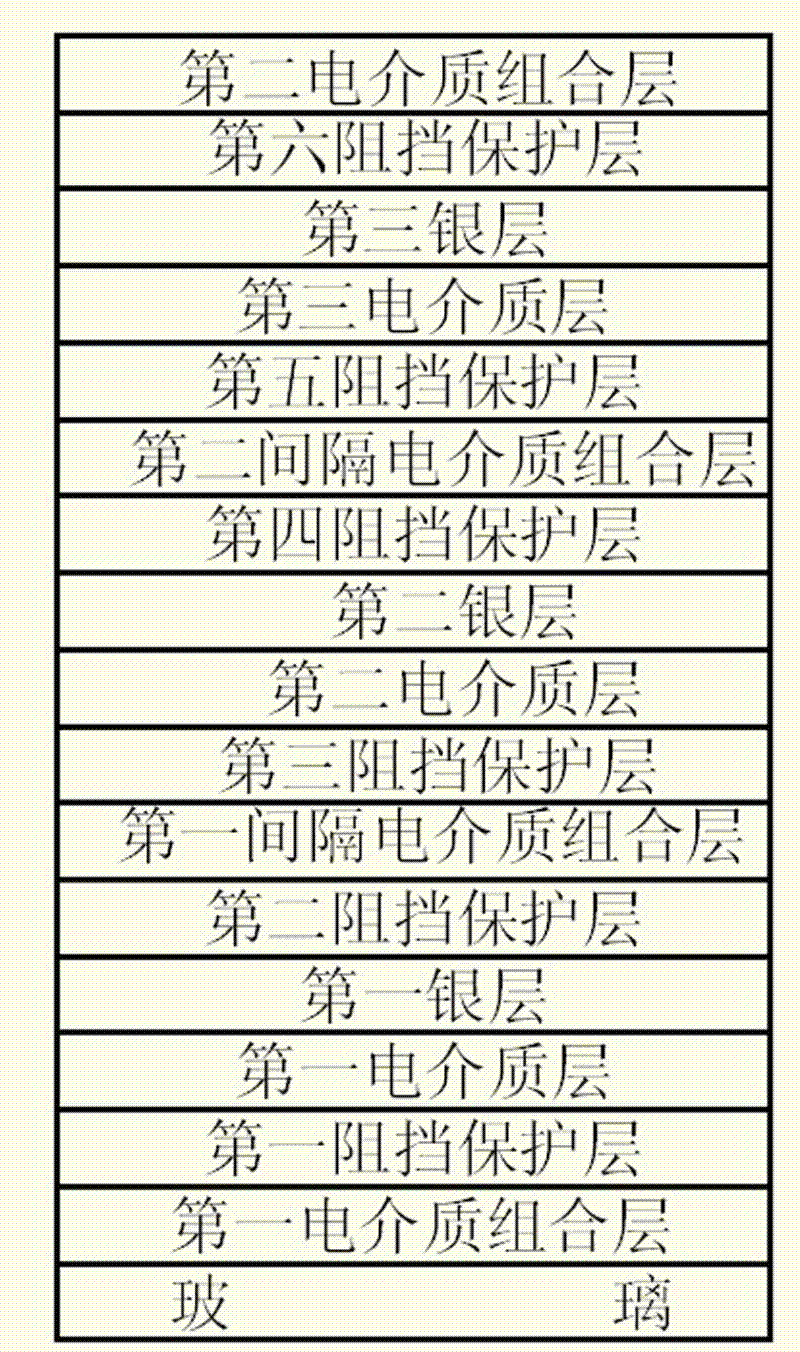

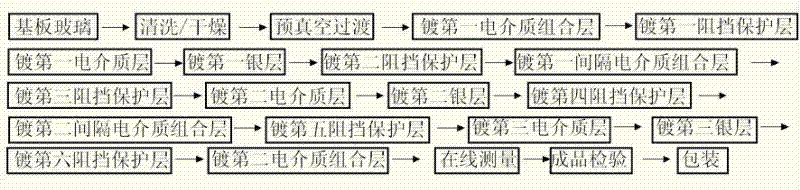

[0035] The film material structure of this embodiment is: glass substrate / SiNxOy / NiCrOx / AZO / Ag / NiCrOx / ZnSnOx / NiCrOx / AZO / Ag / NiCrOx / ZnSnOx / NiCrOx / AZO / Ag / NiCrOx layer / Si 3 N 4 .

[0036] The first dielectric combination layer is silicon oxynitride (SiNxOy), and the thickness of the film layer is: 46nm;

[0037] The first barrier protection layer is nickel chromium oxide (NiCrOx), and the thickness of the film layer is: 0.3nm;

[0038] The first dielectric layer is AZO, and the film thickness is 6nm;

[0039] The thickness of the first silver layer is: 13.9nm;

[0040] The second barrier protection layer is nickel chromium oxide (NiCrOx), and the film thickness is: 0.3nm;

[0041] The first spacer dielectric combination layer is zinc tin oxide (ZnSnOx), and the thickness of the film layer is: 69.7nm;

[0042] The third barrier protection layer is nickel chromium oxide (NiCrOx), and the film thickness is: 0.3nm;

[0043] The second dielectric layer is AZO, and the film thicknes...

Embodiment 2

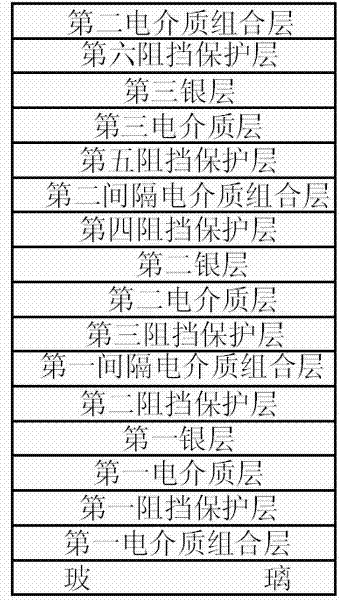

[0079] The film material structure of this embodiment is: glass substrate / SiNxOy / NiCrOx / AZO / Ag / NiCrOx / SiNxOy / NiCrOx / AZO / Ag / NiCrOx / SiNxOy / NiCrOx / AZO / Ag / NiCrOx / SiNxOy / Si 3 N 4 . The combination layer may be a combination of single layers composed of multiple materials.

[0080] Wherein, the first dielectric combination layer is silicon oxynitride (SiNxOy), and the film thickness is: 48.0nm;

[0081] The first barrier protection layer is nickel chromium oxide (NiCrOx), and the thickness of the film layer is: 0.3nm;

[0082] The first dielectric layer is AZO, and the film thickness is 8nm;

[0083] The film thickness of the first silver layer is: 13.5nm;

[0084] The second barrier protection layer is nickel chromium oxide (NiCrOx), and the film thickness is: 0.3nm;

[0085] The first spacer dielectric combination layer is silicon oxynitride (SiNxOy), and the thickness of the film layer is: 68.2nm;

[0086] The third barrier protection layer is nickel chromium oxide (NiCrOx)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com