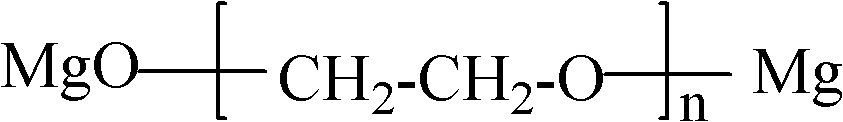

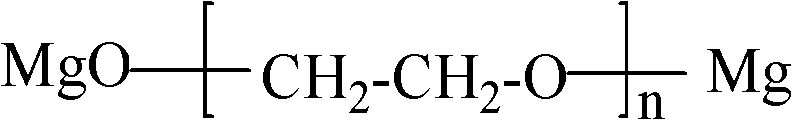

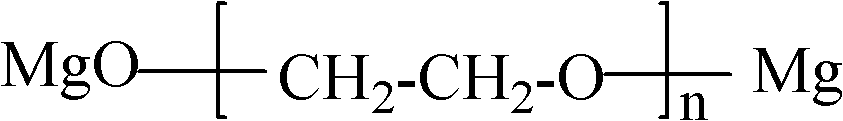

Polyethylene glycol magnesium and preparation method and application thereof

A polyethylene glycol, scheme technology, applied in the field of polyethylene glycol magnesium and its preparation, can solve the problems of lack of reach, polyester influence, expensive price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] After mixing polyethylene glycol with a number average molecular weight of 200 and magnesium oxide in a molar ratio of 3:1, they are heated to react, and the reaction temperature is controlled at 160°C. Condensation and reflux are used to continuously remove the water vapor generated in the reaction process to promote the formation of the product; after 8 hours of reaction, the residual moisture and excess polyethylene glycol in the reactant solution are removed by vacuum decompression distillation, and the vacuum The temperature is controlled at -0.06MPa; after vacuum distillation for 2 hours, the final product is taken out for cooling, crystallized at room temperature and suction filtered, and then the crystal product is washed with absolute ethanol and placed in a vacuum oven at a temperature of 80°C It is dried in a vacuum chamber with a vacuum degree of -0.01MPa, and finally white crystalline particles are obtained, which is the product polyethylene glycol magnesium...

Embodiment 2

[0027] After mixing polyethylene glycol with a number average molecular weight of 200 and magnesium hydroxide in a molar ratio of 3:1, they are heated to react, and the reaction temperature is controlled at 160°C. Condensation and reflux are used to continuously remove the water vapor generated in the reaction process to promote the formation of the product; after 8 hours of reaction, the residual moisture and excess polyethylene glycol in the reactant solution are removed by vacuum decompression distillation, and the vacuum The temperature is controlled at -0.06MPa; after vacuum distillation for 2 hours, the final product is taken out for cooling, crystallized at room temperature and suction filtered, and then the crystal product is washed with absolute ethanol and placed in a vacuum oven at a temperature of 80°C It is dried in a vacuum chamber with a vacuum degree of -0.01MPa, and finally white crystalline particles are obtained, which is the product polyethylene glycol magne...

Embodiment 3

[0030] After mixing polyethylene glycol with a number average molecular weight of 400 and magnesium oxide at a molar ratio of 5:1, they are heated to react, and the reaction temperature is controlled at 170°C. Condensation and reflux are used to continuously remove the water vapor generated during the reaction to promote the formation of the product; after 9 hours of reaction, vacuum distillation is used to remove the residual moisture and excess polyethylene glycol in the reactant solution. The temperature is controlled at -0.07MPa; after vacuum distillation for 3 hours, the final product is taken out for cooling, crystallized at room temperature and suction filtered, and then the crystal product is washed with absolute ethanol and placed in a vacuum oven at a temperature of 80°C It is dried in the middle, and the vacuum degree is controlled at -0.02MPa, and finally white crystalline particles are obtained, which is the product polyethylene glycol magnesium. The obtained poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cold crystallization temperature | aaaaa | aaaaa |

| Cold crystallization temperature | aaaaa | aaaaa |

| Cold crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com