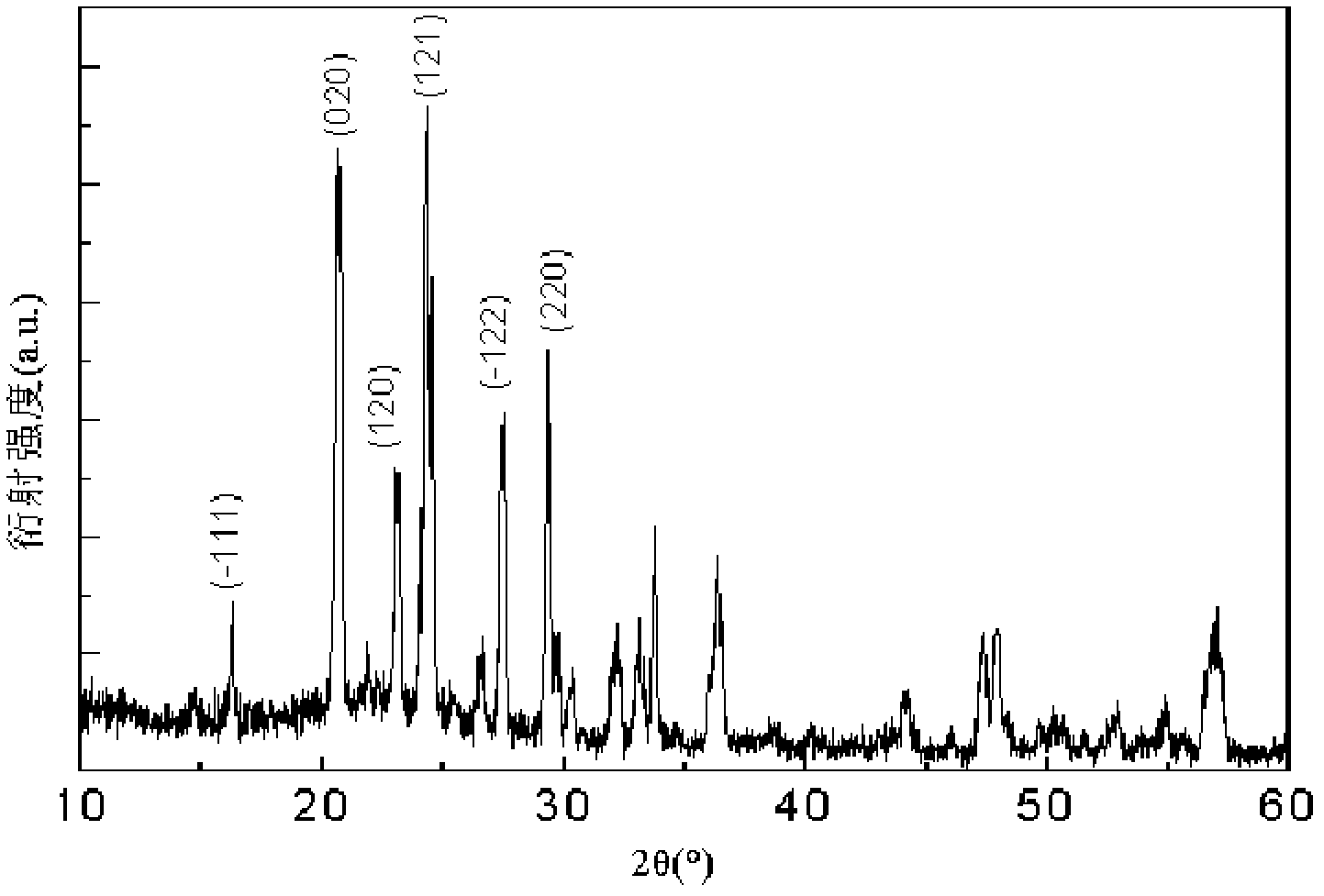

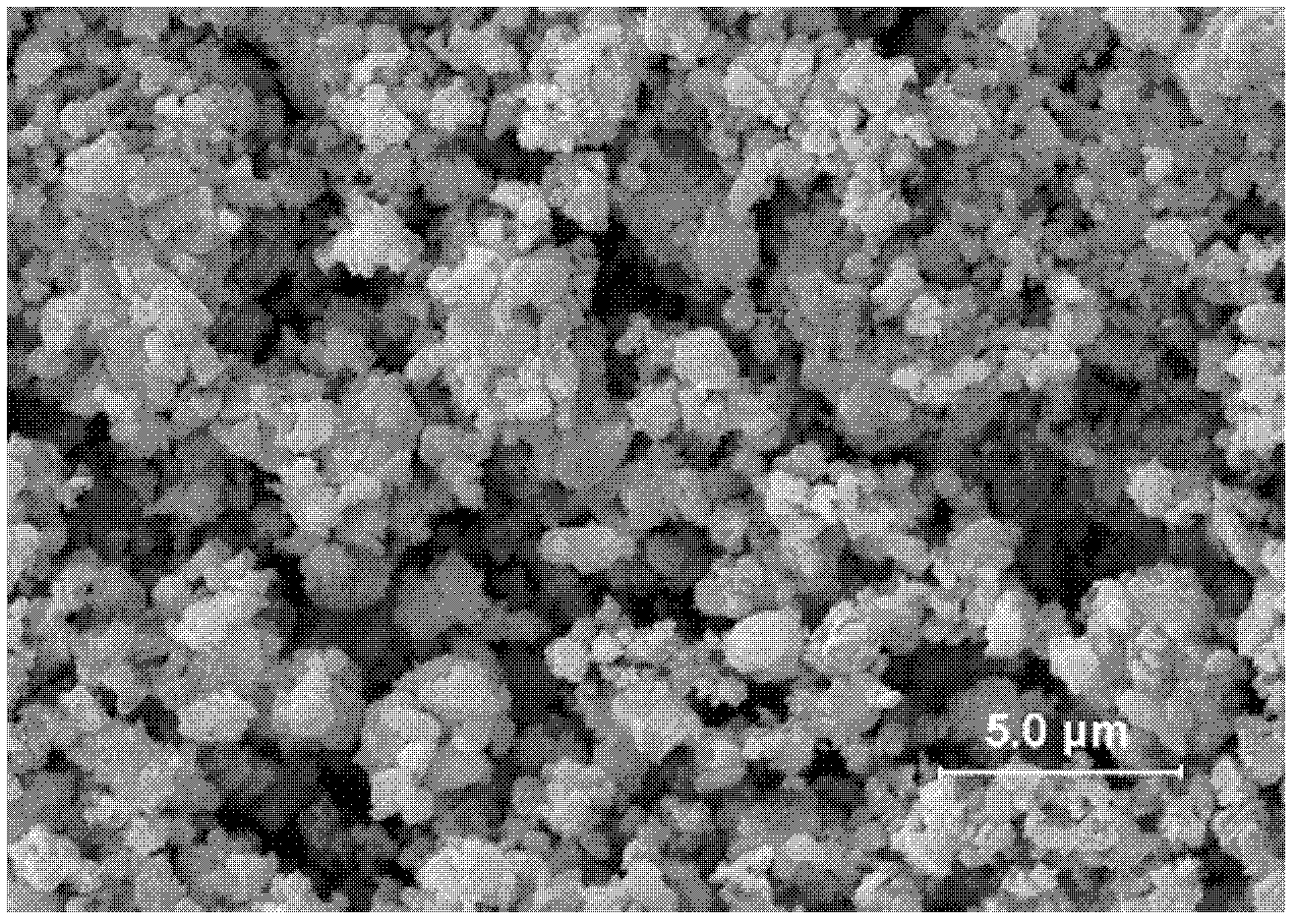

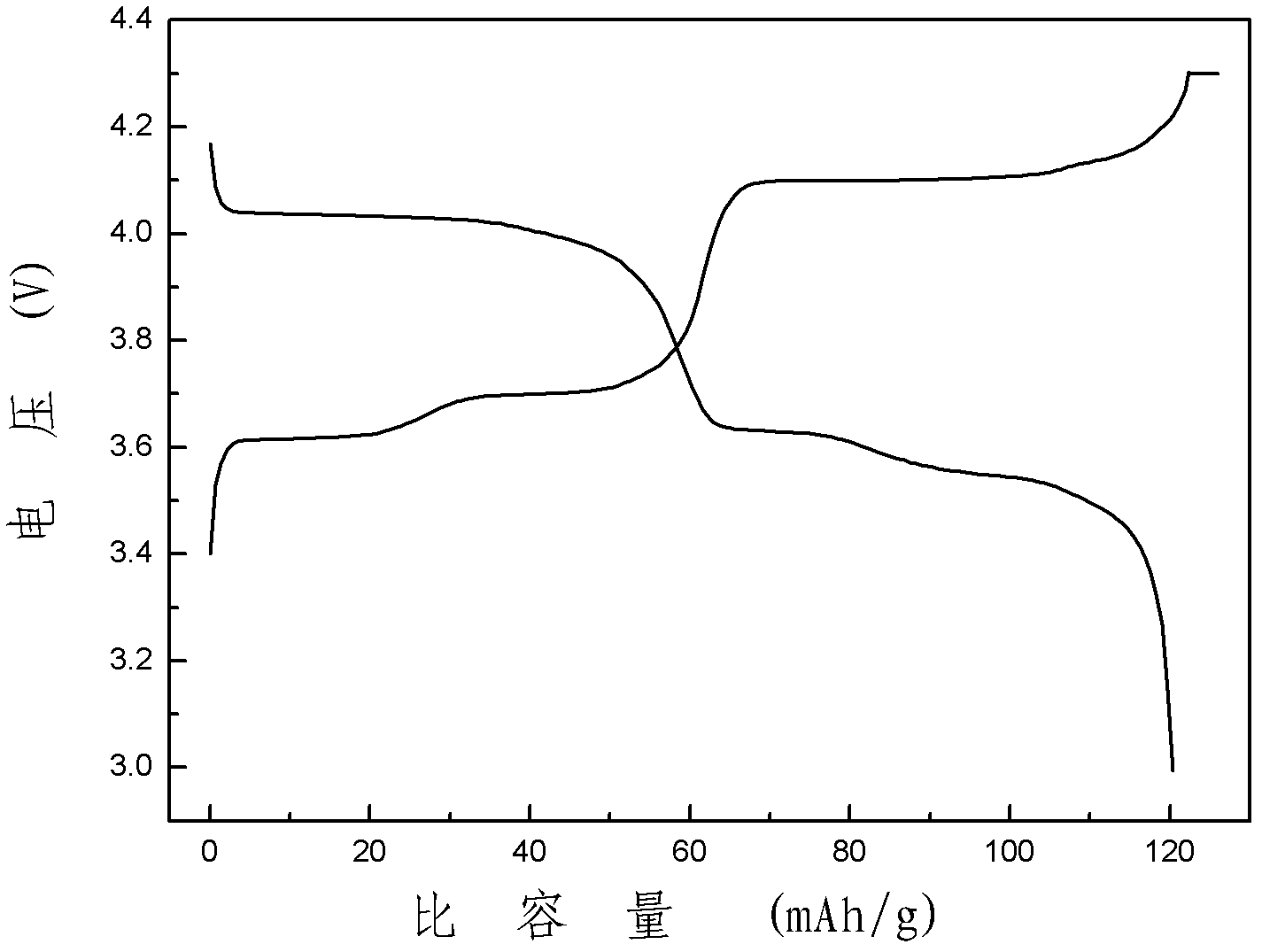

Preparation method of lithium ion battery anode material Li3V2(PO4)3

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of explosive sol-gel process, flammability in spray drying process, and high synthesis temperature, so as to reduce potential safety hazards, The effect of suppressing excessive growth and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific implementation mode one: the present implementation mode is a lithium-ion battery cathode material Li 3 V 2 (PO 4 ) 3 The preparation method is carried out according to the following steps: one, the ratio of the amount of substance of Li element, V element, P element and C element is (3~3.2): 2: 3: (2.5~3) The ratio takes lithium source , V 2 o 5 , phosphorus source and carbon source, the weighed solid material is placed in a ball mill, and a volume fraction of 1% to 5% hydrogen peroxide aqueous solution is added for wet ball milling to obtain a precursor, wherein the ratio of solid material to hydrogen peroxide aqueous solution 3g: (5mL ~ 15mL); 2. Under the protection of protective gas, the precursor obtained in step 1 is calcined for 7 ~ 9h at a temperature of 550 ~ 650 ° C, and cooled to room temperature to prepare the lithium ion battery cathode material Li 3 V 2 (PO 4 ) 3 .

[0011] The used ball of ball milling in this embodiment can adopt stee...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, the material ratio of Li element, V element, P element and C element is (3.05~3.15):2:3:(2.6~ 2.9). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the lithium source described in step one is LiOH·H 2 O, LiF, Li 2 CO 3 and LiCH 3 COO·H 2 One or a combination of O. Others are the same as in the first or second embodiment.

[0015] In this embodiment, when the lithium source is a mixture, various lithium sources can be mixed in any proportion to achieve the required amount of Li element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com