Alkaline earth metal germanate nanomaterial and preparation method thereof and use thereof as cathode material of lithium ion battery

An alkaline earth metal salt and alkaline earth metal technology, applied in battery electrodes, nanotechnology, chemical instruments and methods, etc., can solve the problems of cyclability that cannot meet actual requirements, difficulty in large-scale production, complicated preparation process, etc. The effect of poor performance, easy availability of raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, the preparation of calcium germanate nanomaterial and its electrochemical performance test

[0037] According to Ca(CH 3 COO) 2 ·H 2 O:GeO 2 = 2:7 The ratio of the amount of the substance is weighed, ultrasonically stirred in water for 30min, mixed evenly and then transferred to the lining of a 25mL polytetrafluoroethylene autoclave, which is put into a stainless steel autoclave and heated at 10°C / min heating rate, from room temperature to 180 ° C, and maintained for 24 hours, then naturally cooled to room temperature, washed with deionized water three times, centrifuged and dried to obtain a white powder.

[0038] Characterization of calcium germanate nanomaterials:

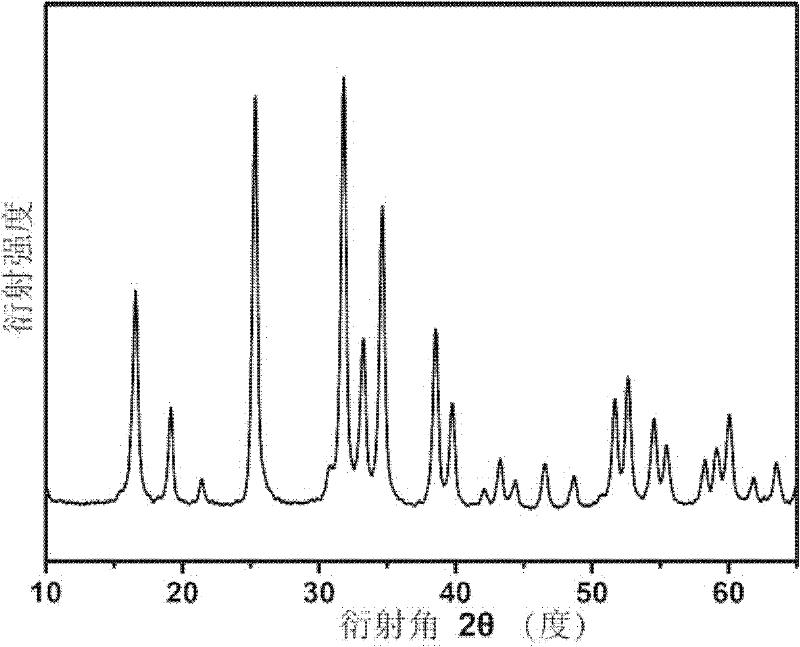

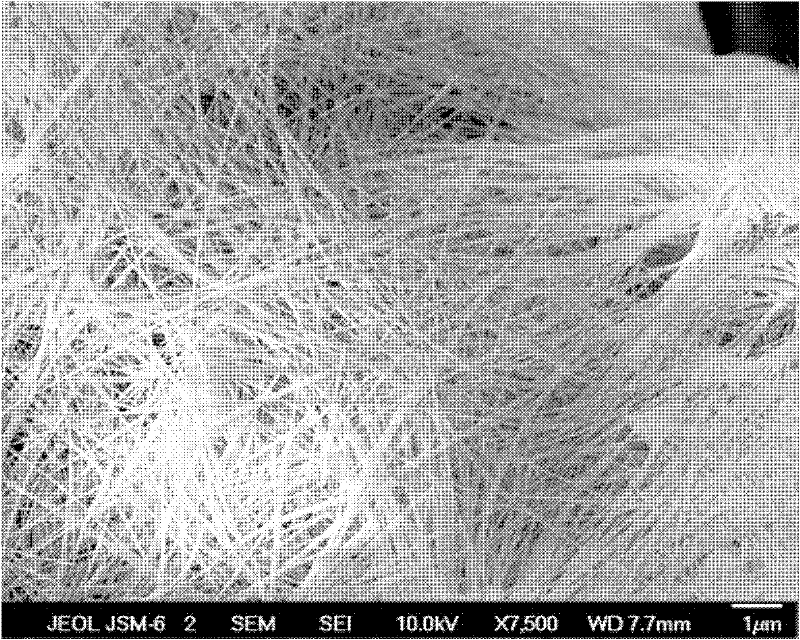

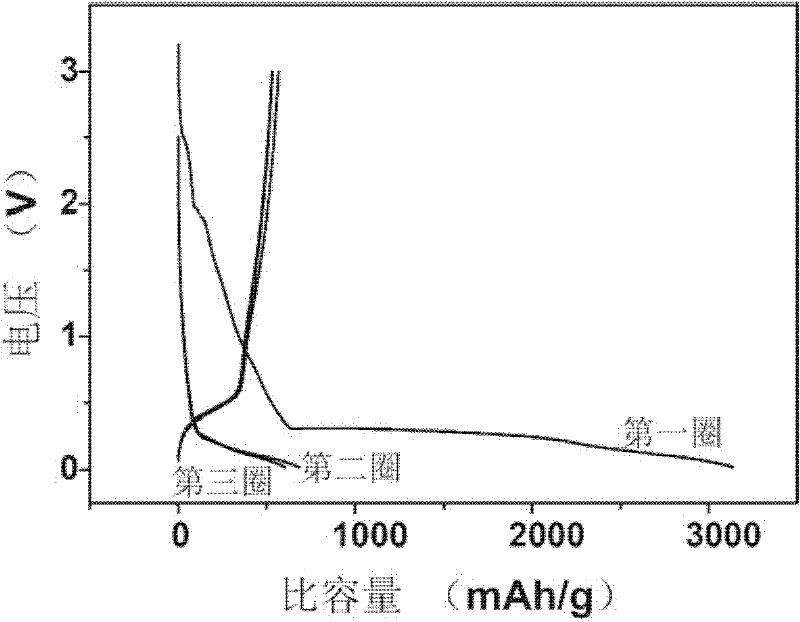

[0039] Powder X-ray diffractometer (Rigaku DmaxrB, CuK α ray) analysis to determine the structure, the results are as follows figure 1 shown. As can be seen from the figure, there is no impurity peak in the spectrogram, indicating that the product has high purity and is the target prod...

Embodiment 2

[0044] Embodiment 2, the preparation of calcium germanate nanomaterial and its electrochemical performance test

[0045] According to Ca(OH) 2 :GeO 2 = 1:1 The ratio of the amount of the substance is weighed, ultrasonically stirred in water for 30min, mixed evenly and then transferred to the lining of a 50mL polytetrafluoroethylene autoclave, which is put into a stainless steel autoclave and heated at 20 ° C. / min heating rate, from room temperature to 200 ° C, and maintained for 48 hours, then naturally cooled to room temperature, washed with deionized water three times, centrifuged and dried to obtain a white powder.

[0046] The structure confirmation results and the apparent physical form, length and diameter of the white powder are the same as in Example 1.

[0047] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are exactly the same as in Example 1. The calcium germanate prepared in this example and the test results...

Embodiment 3

[0048] Embodiment 3, the preparation of calcium germanate nanomaterial and its electrochemical performance test

[0049] According to Ca(CH 3 COO) 2 ·H 2 O:GeO 2 = 2:1 The ratio of the amount of the substance is weighed, ultrasonically stirred in water for 30min, mixed evenly and then transferred to the lining of a 25mL polytetrafluoroethylene autoclave, which is placed in a stainless steel autoclave and heated at 30 ° C. / min heating rate, from room temperature to 200 ° C, and maintained for 24 hours, then naturally cooled to room temperature, washed with deionized water three times, centrifuged and dried to obtain a white powder.

[0050] The structure confirmation results and the apparent physical form, length and diameter of the white powder are the same as in Example 1.

[0051] The positive electrode, negative electrode, electrolyte and battery assembly of the simulated battery are the same as in Example 1. The calcium germanate prepared in this example and the test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com