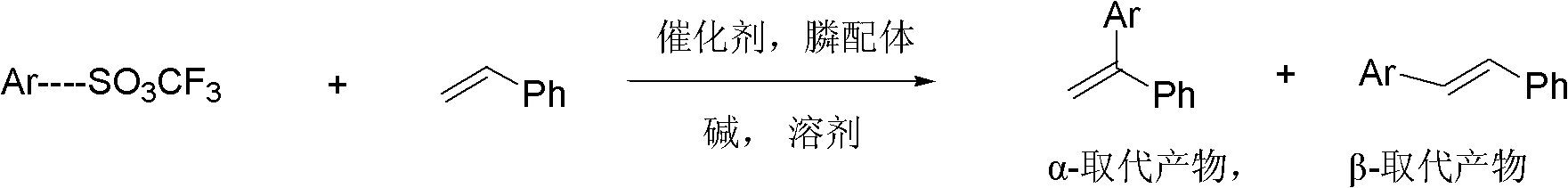

Preparation method of diphenyl ethylene compound

A technology of stilbenes and compounds, which is applied in the field of high-selectivity Heck reaction to prepare stilbenes, can solve problems such as applicability, and achieve mild reaction conditions, high reaction regioselectivity and yield, and efficient reaction. Simple effect of post-treatment purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 9.2 mg (0.016 mmol) of bis(dibenzylideneacetone) palladium and 18 mg (0.032 mmol) of 1,1'-bis(diphenylphosphine) in a dry reaction tube equipped with magnetic stirring and filled with nitrogen ) ferrocene, 10 milliliters of N, N-dimethylacetamide, stirred at room temperature for 10 minutes, then added 181 milligrams (0.8 mmol) of phenyl triflate, 195 milligrams (1.6 mmol) of 4-dimethylamino Pyridine, 166mg (1.6mmol) styrene, reacted at 120°C for 12h.

[0021] After the completion of the reaction as detected by TLC, the solvent was removed under reduced pressure, and the product was separated by column chromatography to obtain 127 mg of the product, with a yield of 88%. The molar ratio ratio of α-substituted product and β-substituted product is 1:16.

Embodiment 2

[0023] Add 4.5mg (0.02mmol) of palladium acetate and 16.2mg (0.04mmol) of 1,3-bis(diphenylphosphine)propane, 10ml of N,N -Dimethylacetamide, stirred at room temperature for 10 minutes, then added 240 mg (1 mmol) p-methylphenyl triflate, 276 mg (2 mmol) potassium carbonate, 208 mg (2 mmol) styrene, and reacted for 16 h.

[0024] After the completion of the reaction as detected by TLC, the solvent was removed under reduced pressure, and the product was separated by column chromatography to obtain 165 mg of the product, with a yield of 85%. The molar ratio ratio of α-substituted product and β-substituted product is 1:18.

Embodiment 3

[0026] The same method as in Example 1 was used, wherein the reaction temperature was 122°C. After the reaction was complete as detected by TLC, the solvent was removed under reduced pressure, and the product was separated by column chromatography to obtain 123 mg with a yield of 85%. The molar ratio of the α-substituted product and the β-substituted product was 1:14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com