Method for continuously discoloring succinic acid fermentation liquor by using activated carbon

A technology of succinic acid and fermentation broth, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low utilization rate of activated carbon, high labor intensity, equipment corrosion, etc., and achieve easy regeneration. , low labor intensity, and the effect of reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

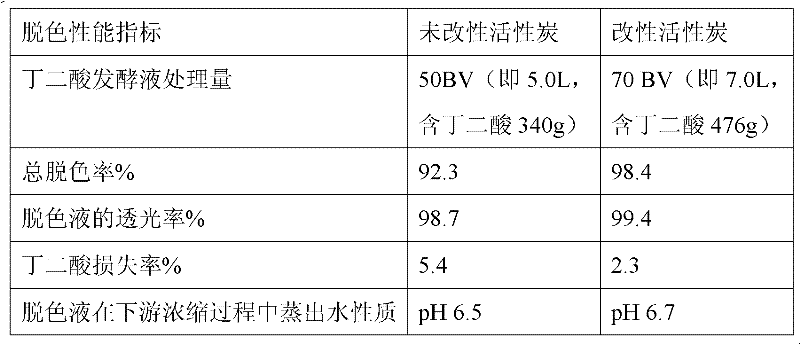

Image

Examples

Embodiment 1

[0029] In this implementation, the particle size of the fruit shell activated carbon particles is 50 mesh; the succinic acid fermentation liquid is processed by ultrafiltration, and the concentration of succinic acid is 48g / L; the pigment content is represented by the light transmittance at 430nm, and pure water is used as a reference , light transmittance 37.2%; pH 6.8. The specific decolorization method is carried out in the following steps.

[0030] (1) Add the granular activated carbon into the NaOH solution with a concentration of 0.5mol / L according to the ratio of 0.4% (w / w), stir at 50°C at a speed of 100 rpm for 40 minutes, then filter, and use the filter to remove water The modified activated carbon was washed with deionized water to pH 7, and 33 g of the modified granular activated carbon was packed into the chromatographic column. The activated carbon bed volume (BV) was 100 mL, and the aspect ratio was 18.

[0031] (2) Heat the succinic acid fermentation broth to ...

Embodiment 2

[0038] In this implementation, the particle size of the shell activated carbon particles is 70 mesh; the succinic acid fermentation liquid is processed by ultrafiltration, and the concentration of succinic acid is 56g / L; the pigment content is represented by the light transmittance at 430nm, and pure water is used as a reference , light transmittance is 56.6%; pH 6.5. The specific decolorization method is carried out in the following steps.

[0039] (1) Add the granular activated carbon into the NaOH solution with a concentration of 0.5mol / L according to the ratio of 0.5% (w / w), stir at 50°C at a speed of 100 rpm for 40 minutes, filter, and use The modified activated carbon was washed to pH 8 with deionized water, and 33 g of the modified granular activated carbon was packed into the chromatographic column. The activated carbon bed volume (BV) was 100 mL, and the aspect ratio was 8.

[0040] (2) Heat the succinic acid fermentation broth to 70°C, put it on the column (single chr...

Embodiment 3

[0047] In this implementation, the particle size of the shell activated carbon is 20 meshes; the succinic acid fermentation broth is treated by ultrafiltration, and the concentration of succinic acid is 74g / L; the pigment content is represented by the light transmittance at 430nm, and pure water is used as a reference , light transmittance 58.5%; pH 6.6. The specific decolorization method is carried out in the following steps.

[0048] (1) Add the granular activated carbon into the NaOH solution with a concentration of 0.3mol / L according to the ratio of 0.4% (w / w), stir at 60°C at a speed of 100 rpm for 50 minutes, then filter, and use the filter to remove water Deionized water washes the modified activated carbon to pH7.5, and the modified granular activated carbon 99g is packed into a chromatographic column, and three activated carbon chromatographic columns (respectively I, II, III) that the ratio of height to diameter is 4.5 are filled respectively. ), the activated carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com