Phosphorescence iridium complex, preparation method and organic electroluminescent device

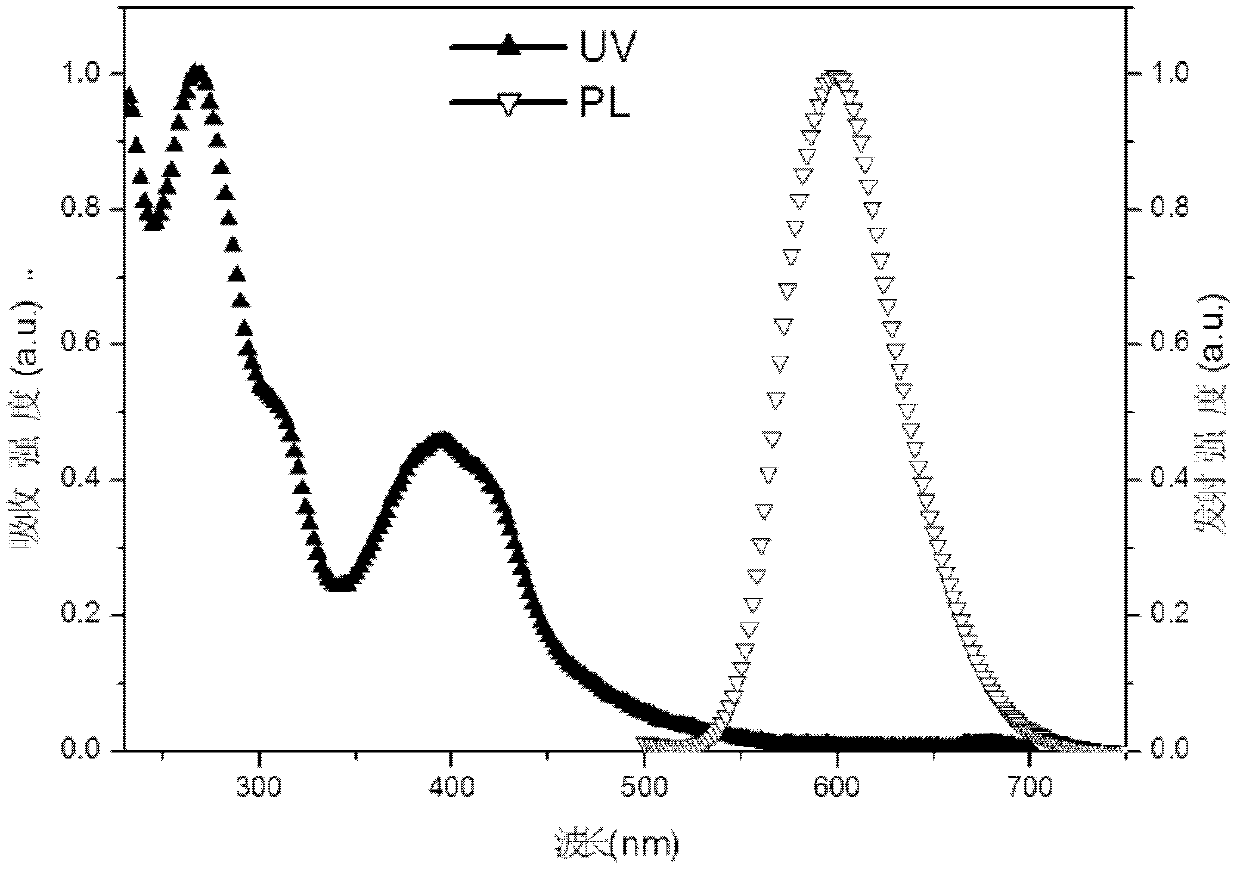

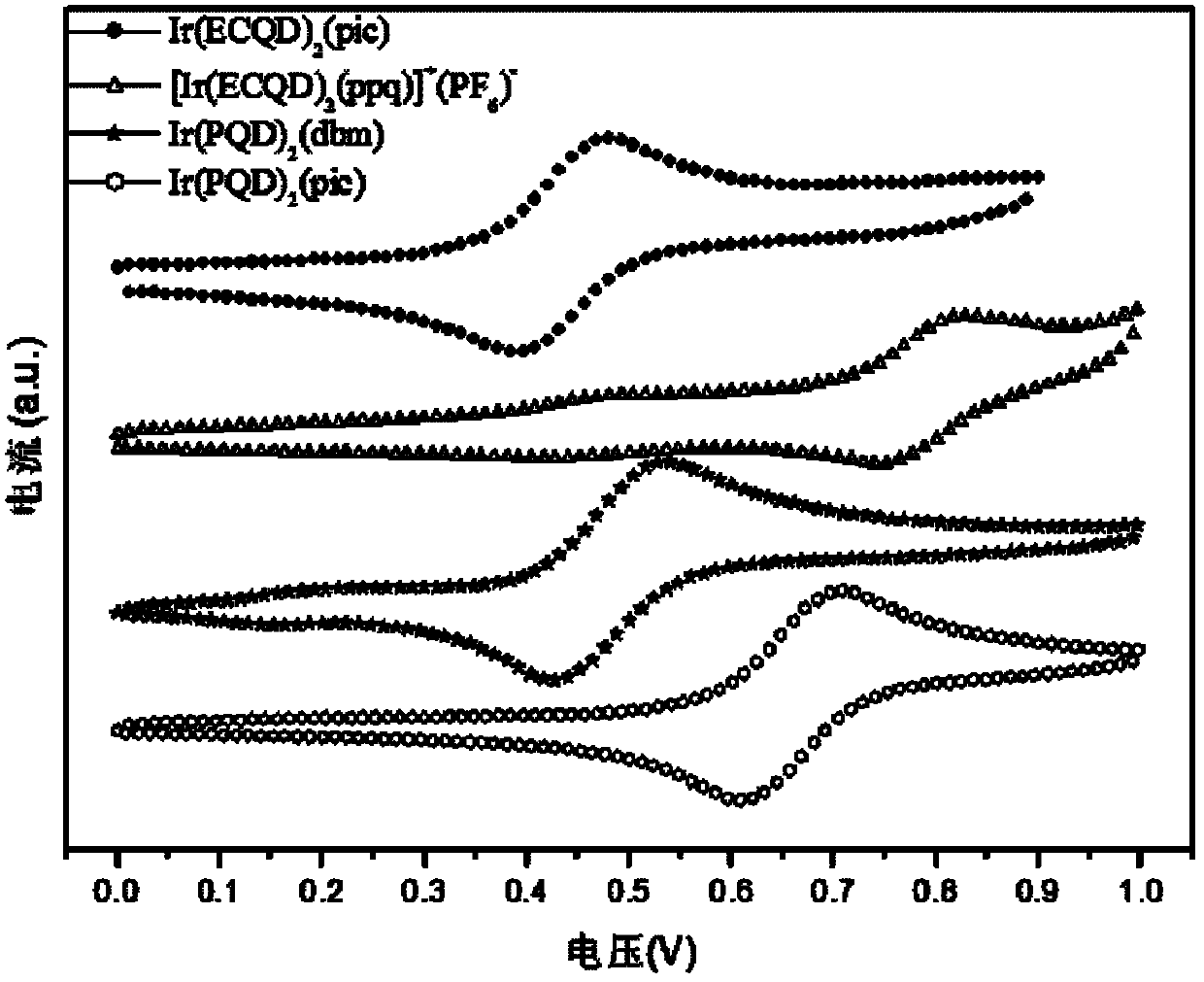

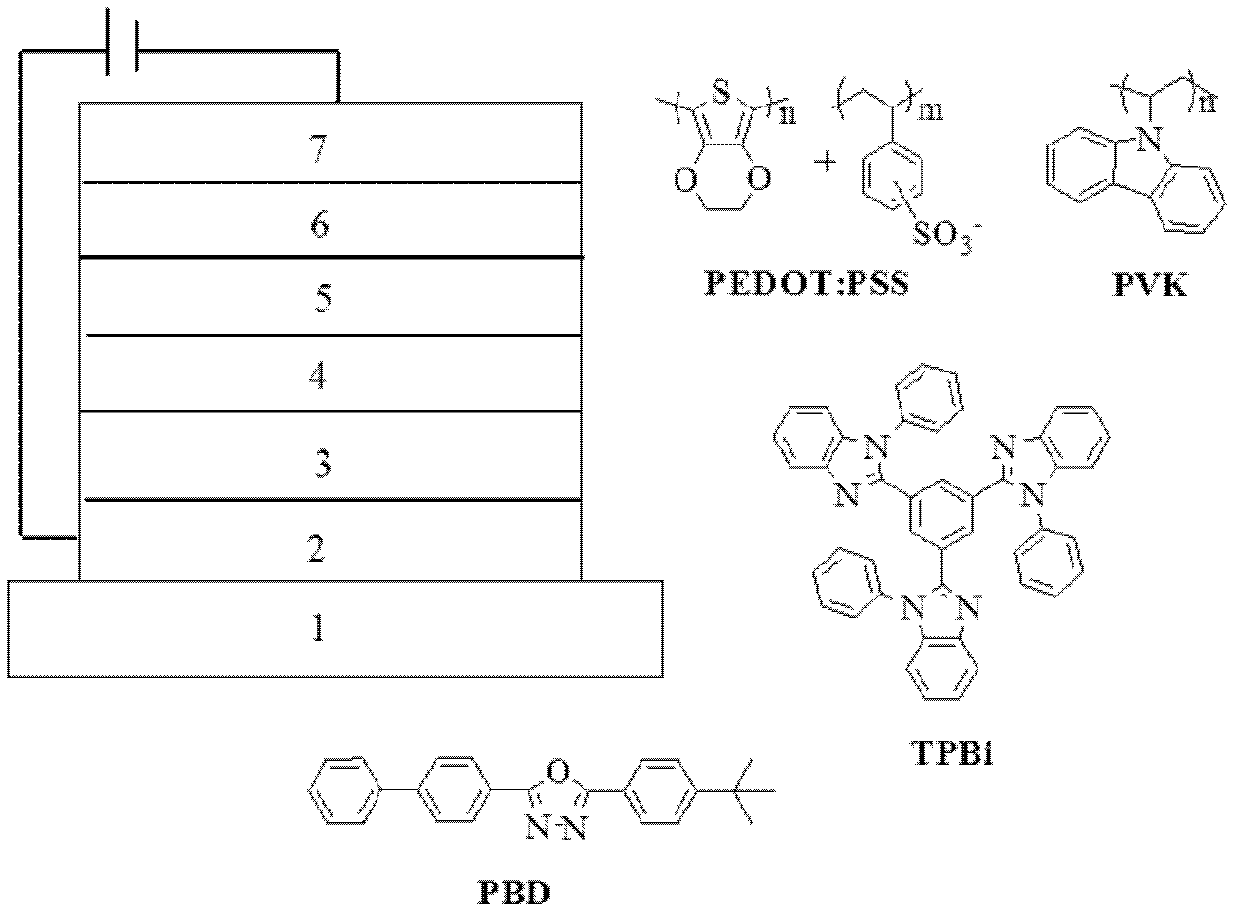

A technology of phosphorescent iridium complexes and complexes, applied in the fields of electric solid devices, electrical components, organic chemistry, etc., can solve the problems of reducing the luminous efficiency of devices, achieve high internal and external quantum yields, easy purification, and improve solubility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of ligand HPQD

[0032] Weigh 4.08g (30mmol) anthranilamide and 6.24g (60mmol) NaHSO 3 Add two-neck bottle, N 2 Add 30mL of N,N-dimethylacetamide and 3.18g (30mmol) of benzaldehyde under protection, raise the temperature to 150°C and stir for 8h, after the reaction is completed, cool to room temperature, pour the reaction solution into a large amount of water, a white precipitate appears, and filter with suction , washed with water and ethanol respectively, and dried to obtain white crystals of 2-phenylquinazolin-4(3H)-one. Yiled: 97.3%. 1 H NMR (DMSO-d 6 , 400MHz) δ (ppm): 7.49-7.58 (m, 4H), 7.72-7.74 (d, 1H), 7.91-7.94 (t, 1H), 8.13-8.18 (t, 3H).

[0033] Weigh 0.47g (2.1mmol) of the above-mentioned 2-phenylquinazolin-4(3H)-one into the two-necked bottle, N 2 Inject 6mLCHCl under protection 3 and 2 mL (21 mmol, ρ=1.675) of POCl 3 , heated to 60°C and stirred for 12h, after the reaction was completed, CHCl was distilled off under re...

Embodiment 2

[0036] Embodiment 2: Complex Ir(PQD) 2 (pic) preparation

[0037] Add 0.528g (1.5mmol) IrCl to the reaction flask 3 ·3H 2 O, add 15 mL of water, then add 1.68 g (4.5 mmol) of ligand HPQD and 45 mL of ethoxyethanol, N 2 Warm up to 100°C under protection, stir for 24 hours in the dark, cool, filter, wash the solid with water and ethanol respectively, and dry to obtain the dichloro bridge compound Ir of iridium 2 (PQD) 4 Cl 2 .

[0038] With 0.7g (0.36mmol) above-mentioned dichloro bridge compound Ir 2 (PQD) 4 Cl 2 Dissolve in 30mL dichloromethane, add 0.5g (3.6mmol) potassium carbonate and 0.22g (1.8mmol) 2-pyridinecarboxylic acid (pic), N 2 React under protection at room temperature for 8 hours, concentrate to obtain the crude product, separate and purify by silica gel chromatography to obtain the red Ir(PQD) 2 (pic) solid. Yield: 68.2%. 1 HNMR (DMSO-d 6 , 400MHz) δ (ppm): 6.58-6.62 (t, 2H), 6.67-6.74 (m, 2H), 6.80-6.84 (t, 1H), 6.92-6.94 (m, 1H), 7.04-7.06 (m, 2H...

Embodiment 3

[0041] Embodiment 3: Complex Ir(PQD) 2 (dbm) preparation

[0042] Weigh 0.2g (0.103mmol) dichloro bridge compound Ir 2 (PQD) 4 Cl 2 Dissolve in 10mL dichloromethane, add 0.12g (0.52mmol) dibenzoylmethane (dbm) and 0.11g (1.03mmol) potassium carbonate, stir at room temperature for 8h, separate and purify by silica gel chromatography to obtain Ir(PQD) 2 (dbm). Yield: 33.5%. 1 H NMR (CDCl 3 , 400MHz) δ(ppm): 6.12(s, 1H), 6.60-6.62(d, 2H), 6.64-6.68(t, 2H), 6.78-6.81(t, 2H), 6.95-6.99(t, 2H) , 7.13-7.14(d, 8H), 7.18-7.24(m, 6H), 7.28-7.39(m, 16H), 7.58-7.59(d, 2H), 7.68-7.70(d, 4H), 8.36-8.39( d, 2H).

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com