Temperature-difference-drive-type self-adapting heat transfer pipe

A technology that adapts to heat and transfer tubes. It is used in tubular elements, heat transfer modification, heat exchange equipment, etc. It can solve problems such as life time limit, complex structure, noise, etc., to achieve rapid transfer, small equipment size, and enhanced heat dissipation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

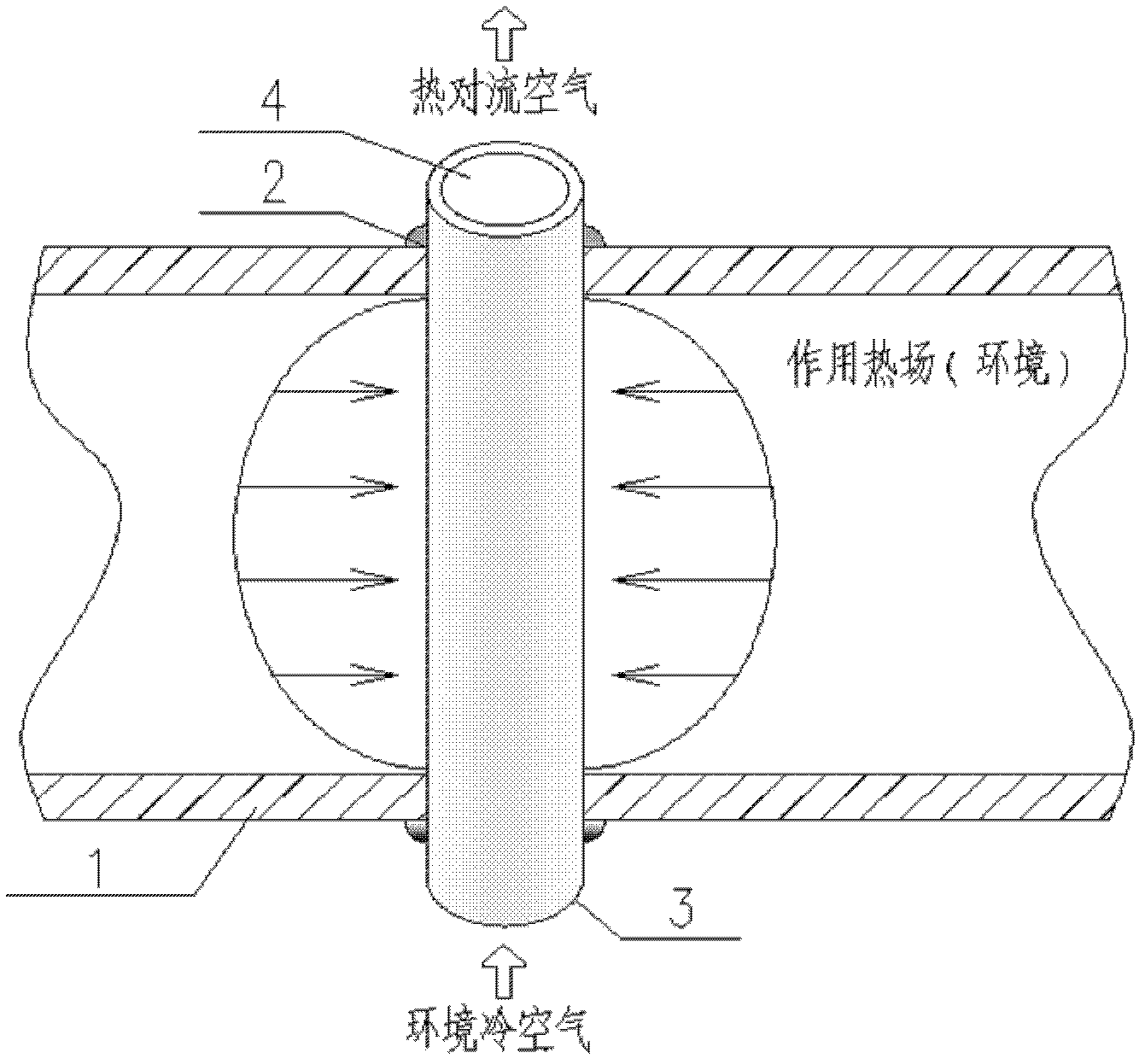

[0065] Embodiment 1, on the outer casing of the heat source body, a number of thin tubes with good thermal conductivity are vertically inserted, which are called temperature difference driven adaptive heat transfer tubes. This type of straight tube can also be called straight-through type. Temperature-difference-driven adaptive heat transfer tube; it can also be used as a through-type fastening bolt, heat source body mounting bracket, etc.; under the condition that the gas can circulate in the tube, the shape is not limited to the round tube, and can be oval, square, Straight-through or curved, deflected tubes of various shapes such as polygons, and even flexible telescopic tubes.

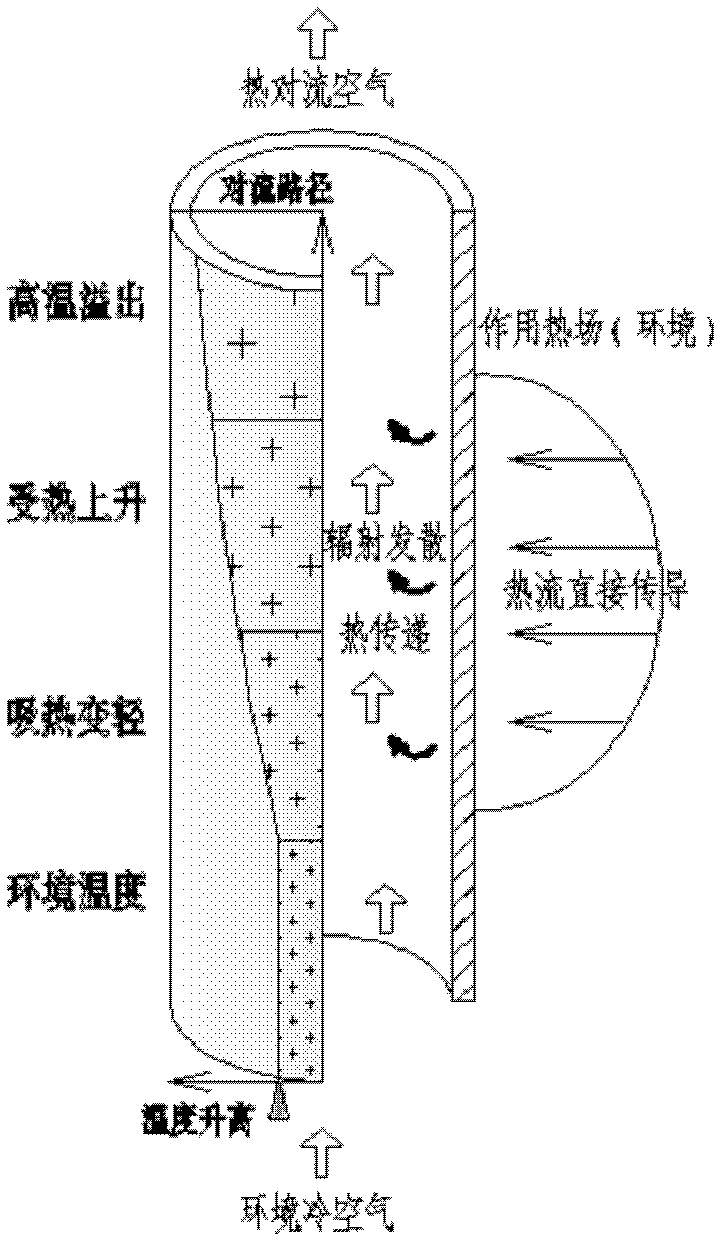

[0066] Its basic principle see figure 1 shown.

[0067] A place close to or directly in contact with the heat source body is selected in advance, and several straight-through temperature difference driven adaptive heat transfer tubes with good thermal conductivity are vertically inserted.

[0068...

Embodiment 2

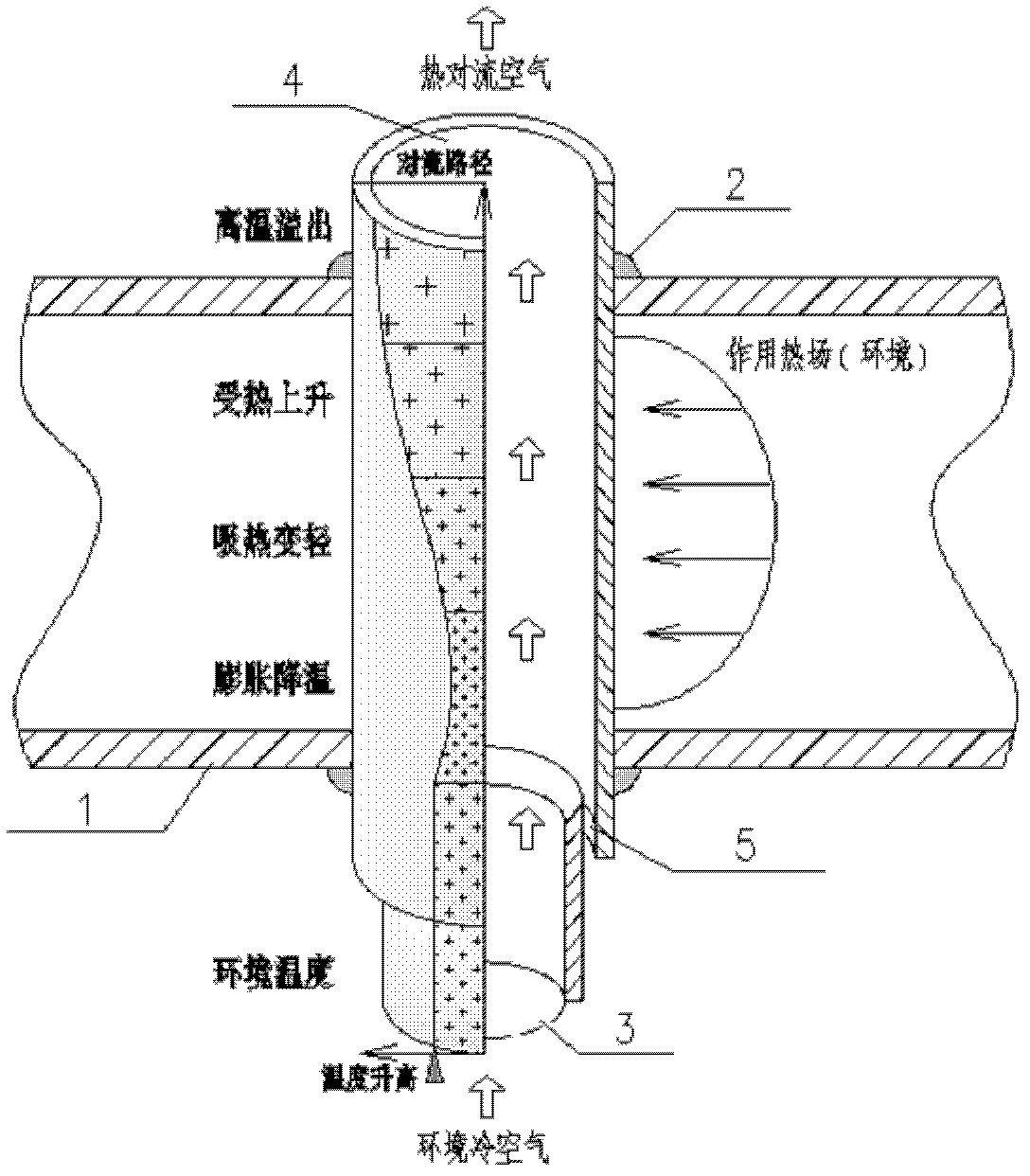

[0079] Example 2, see image 3 ,

[0080] The integrated self-adaptive heat transfer tube is divided into upper and lower parts, the purpose is to increase the diameter of the upper tube, and the lower part forms a throttling part; the upper and lower parts can also be nested with each other, which is embodied as a sleeve connector 5, which constitutes a The improved expanded heat transfer tube is to change the diameter of the upper exhaust port 4 to make it expand larger under the condition that the caliber of the lower air intake port 3 remains unchanged.

[0081] After expanding the shape of the upper part, the lower part and the upper part are formed with an enlarged cavity structure, so that the outside air sucked from the lower part first goes up a short path through the throttle tube, and then expands in the expanded cavity to form a low-pressure environment, which enlarges the air volume. The distance between the molecules also increases the gravitational force betwee...

Embodiment 3

[0090] Example 3, such as Figure 5 As shown, the surface of the upper extended outer layer of the adaptive heat transfer tube is changed to black, that is, blackening the outer layer 6 is conducive to absorbing more heat from the surrounding environment and the inside of the casing, resulting in the air flowing through the adaptive heat transfer tube As the temperature increases further, the thermal convection self-circulation effect is further strengthened;

[0091] 3. In addition to increasing the number of adaptive heat transfer tubes, another way to increase the heat dissipation area is to roughen the outer surface. The specific method is to roughen the outer surface of the self-adaptive heat transfer tube to present a fine, uneven outer surface. The height of the bumps is comparable to the wavelength of the thermal radiation.

[0092] Therefore, the outer surface of the self-adaptive heat transfer tube can also form a blackened and concave-convex outer layer.

[0093]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com