Double clad all-solid-state photonic crystal fiber and preparation method thereof

A photonic crystal fiber, all-solid-state technology, applied in the direction of cladding fiber, multi-layer core/cladding fiber, optical waveguide light guide, etc., can solve the problems of poor fiber system compatibility, difficult control of fiber loss, and high production cost , to achieve the effect of improving heat dissipation performance, increasing laser output power and increasing absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above-mentioned double-clad all-solid-state photonic crystal fiber comprises the following steps:

[0026] ① Preparation of glass rods with uniform outer diameter:

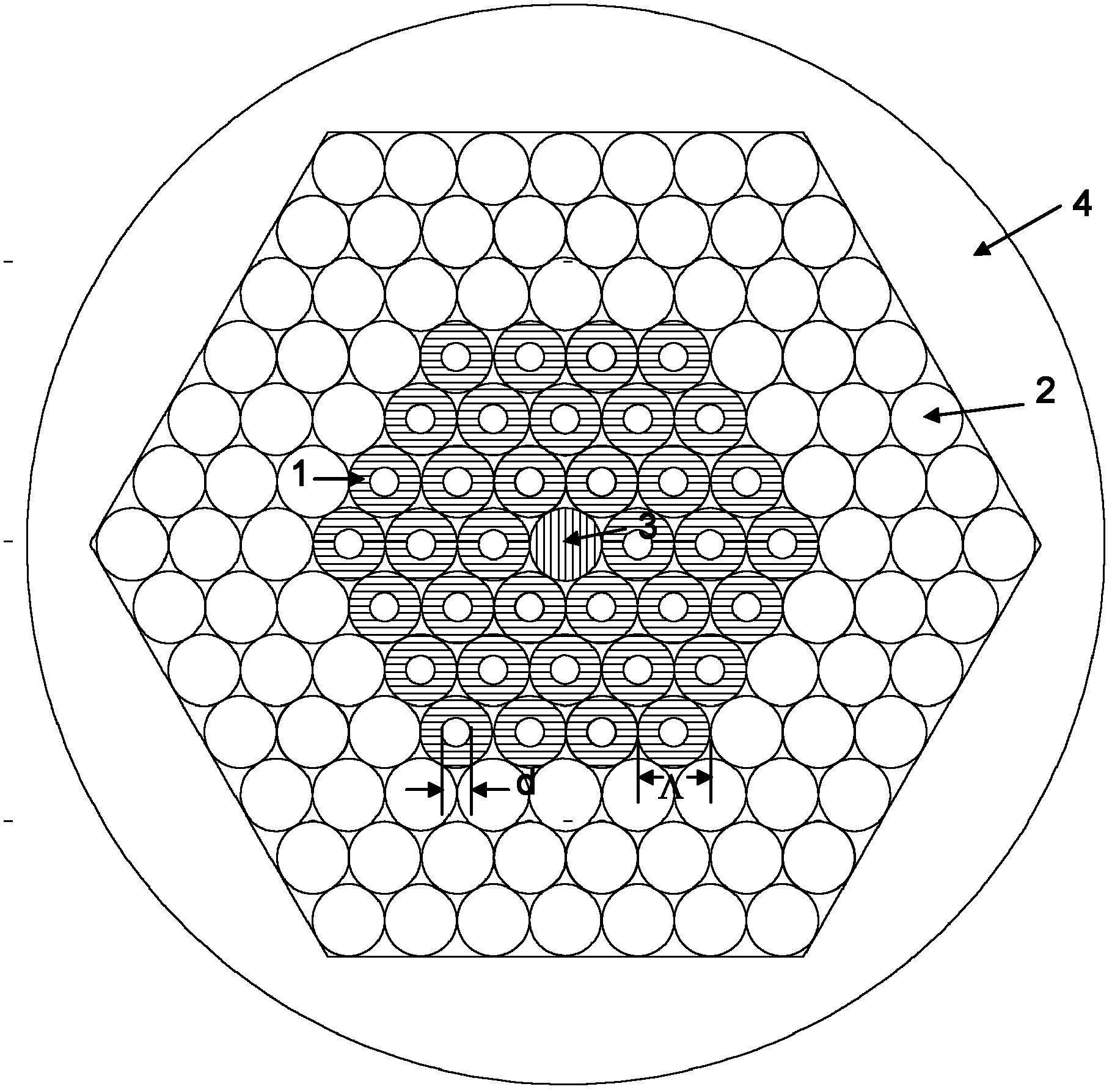

[0027] In the ultra-clean room, the first glass rod 1, the second glass rod 2 and the third glass rod 3 are made by pipe rod method and wire drawing method. The second glass rod 2 is a uniform thin rod of non-doped glass. The three glass rods 3 are uniform thin rods doped with glass, and the first glass rod 1 is a uniform thin rod of cladding glass with a core, the core glass has a lower refractive index, and the outer cladding glass has a lower refractive index. High, then cut the uniform first glass rod 1, the second glass rod 2 and the third glass rod 3 into the same length L according to the requirements of preparing double-clad all-solid-state photonic crystal fiber;

[0028] ②Preparation of optical fiber preform:

[0029] Arrange m layers of the first glass rods 1 in a ...

Embodiment 1

[0034] Using phosphate glass as the matrix glass, the refractive index of the first glass rod 1 (cladding), the second glass rod 2, and the third glass rod 3 are (d line) 1.500, 1.536, 1.537 respectively, the first glass rod 1, The second glass rod 2 is not doped with rare earth, and the third glass rod 3 is Nd doped with a concentration of 3.5×10 20 cm -3 , the outer diameter of the three kinds of glass rods is 1 mm (the error is less than 1%), and the length is 8.5 cm. The softening point of No. 3 glass rods 1, 2, and 3 is between 450°C and 460°C; the inner hexagonal metal sleeve is stacked to form a preform, sintered at 540°C for 15 minutes, and annealed at 430°C for 10 hours to obtain a relatively complete cross section It is a hexagonal prefabricated rod with an outer diameter of 17.5mm. The ratio of the core diameter to the outer diameter of the first glass rod 1 is 6:23, which determines the ratio of the photonic crystal cladding d to Λ. Draw the wire at 600°C (40°C ...

Embodiment 2

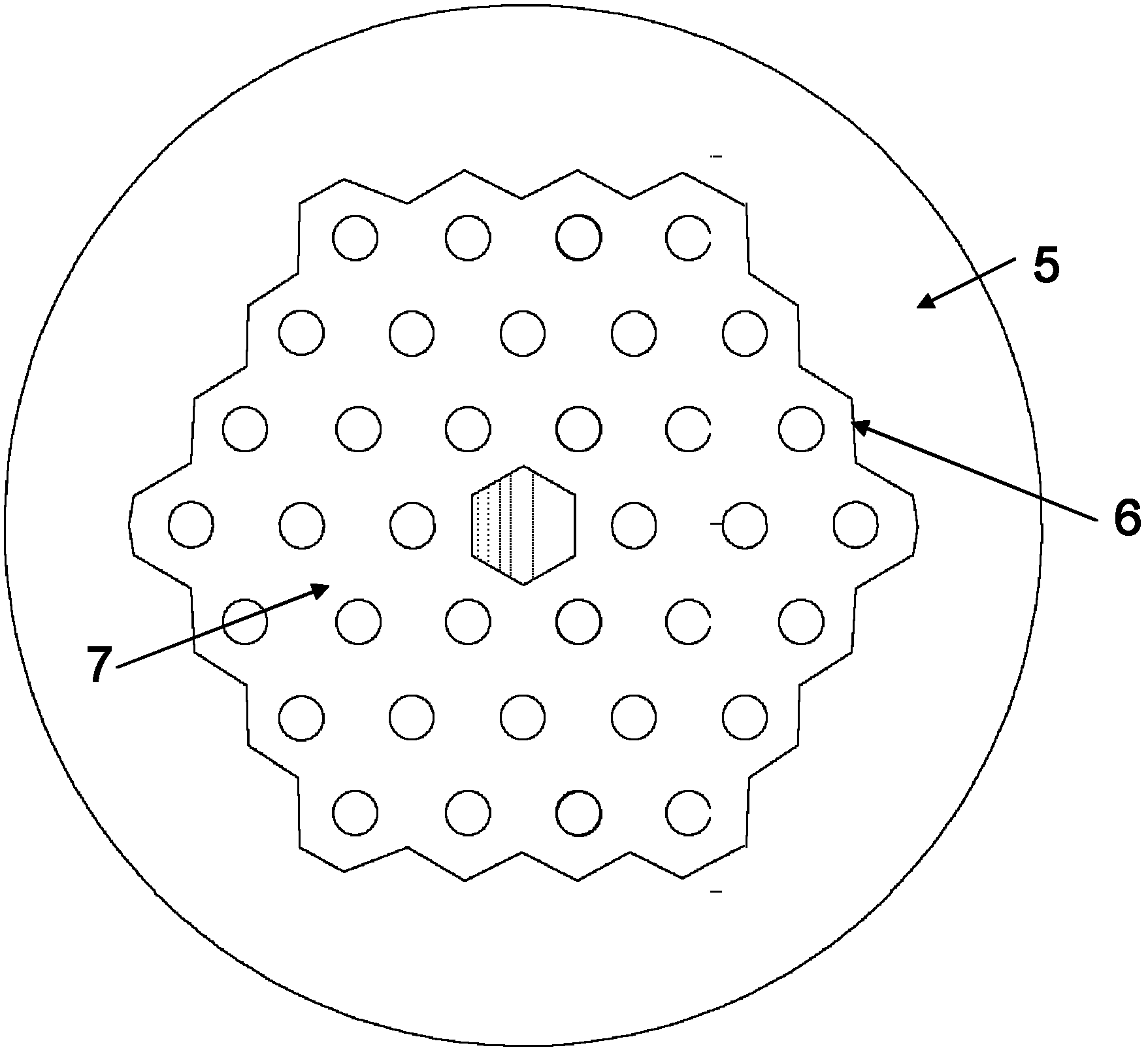

[0037]Quartz glass is used as the matrix material, and the first glass rod 1, the second glass rod 2, and the third glass rod 3 with cladding are respectively ordinary quartz glass, fluorine-doped quartz glass, and rare earth-doped glass, with an outer diameter of 0.6 mm ( The error is less than 2%), and the length is 20cm. The third glass rod 3 is doped with Yb at a concentration of 2000ppm. 25 layers of first glass rods 1 are densely packed in the metal sleeve. Replace the outermost five layers of first glass rods 1 with second glass rods 2, replace the central first glass rod 1 with third glass rod 3, and sinter at 1800° C. for 20 minutes. Draw the filament at 2100°C to obtain a double-clad all-solid-state optical fiber.

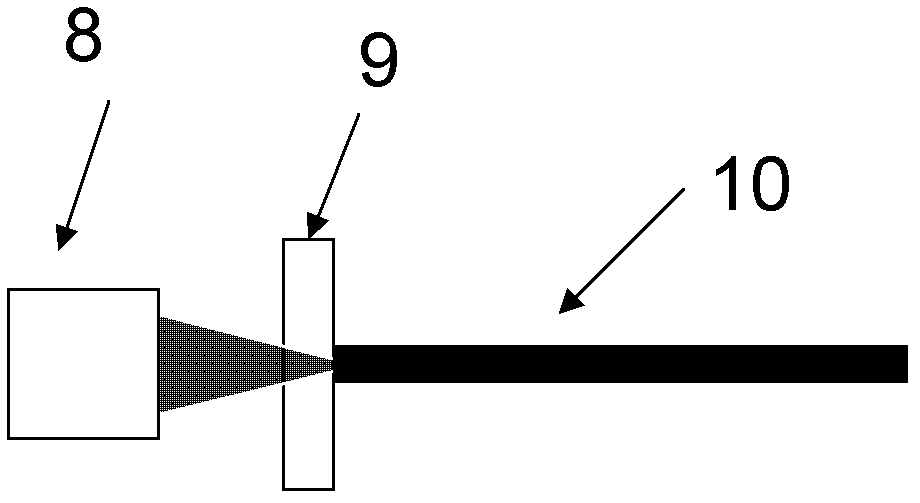

[0038] use image 3 The device detects the absorption coefficient and laser performance of the optical fiber. The absorption coefficient at 976nm reaches 15dB / m, which is more than double that of ordinary double-clad optical fiber (6.5dB / m) obtained fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com