Method for preparing doped ferrous-lithium metasilicate anode material from micro silicon powder

A technology of lithium ferrosilicate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of slow lithium ion diffusion and low electronic conductivity, and achieve good cycle performance, high charge-discharge capacity, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Weigh 4.72g of silica fume, put it into a 100ml beaker filled with 50m / 4mol / L hydrochloric acid solution, heat to boiling, and remove the contained Fe 2 o 3 、Al 2 o 3 , MgO, CaO and NaO, the main content is Fe 2 o 3 , filtered and washed until the filtrate was colorless, then dried to obtain 3.59g of treated silica fume, Fe 2 o 3 The weight of etc. is 1.13g, and content is 24%. Weigh 1.00 g of the micro-silicon powder, and measure the carbon content of the micro-silicon powder as 5% by the 800° C. high temperature ignition weight loss method. Therefore, SiO in silica fume 2 The content is 71%.

[0027] Weigh ferrous oxalate (4.66g), microsilica (3.39g), lithium carbonate (2.96g) and sucrose (0.70g) into a ball mill jar, ball mill and mix in absolute ethanol, then vacuum dry at 60°C A precursor mixture is obtained. The precursor is pressed into tablets, pre-calcined at 400°C for 3 hours in nitrogen, and then roasted at 750°C for 8 hours. During the solid-state r...

Embodiment 2

[0030] According to the SiO of the microsilica powder of embodiment 1 2 content, designed to prepare ion-doped Li 2 FeSiO 4 / C composite cathode material. Weigh ferrous oxalate (4.66g), microsilica (3.39g), lithium carbonate (2.96g) and sucrose (3.91g) into a ball mill jar, ball mill and mix in absolute ethanol, then vacuum dry at 60°C A precursor mixture is obtained. The precursor is pressed into tablets, pre-calcined at 400°C for 3 hours in nitrogen, and then roasted at 750°C for 8 hours. During the solid-state reaction at high temperature, the ferric iron is reduced to ferrous iron by carbon (the carbon is sucrose pyrolysis Carbon or the carbon contained in microsilica powder), to obtain ion-doped Li 2 FeSiO 4 / C composite positive electrode material, the dopant ion is Al contained in micro-silicon powder 3+ , Mg 2+ , Ca 2+ and Na + Wait. Assemble the button battery according to the method described in Example 1, and under the charge and discharge voltage range of...

Embodiment 3

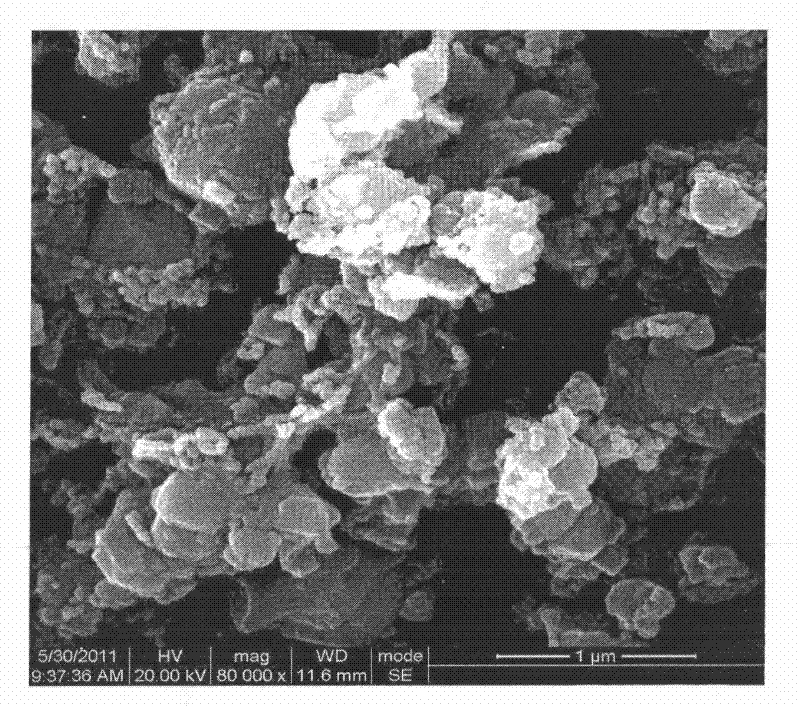

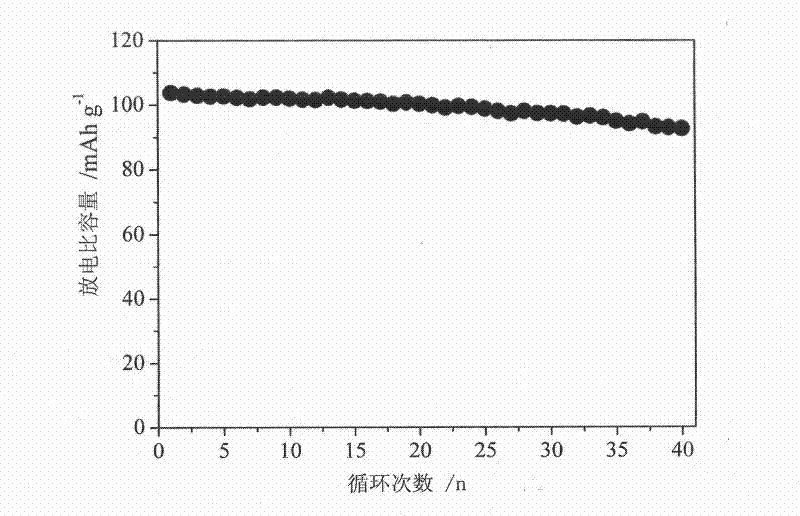

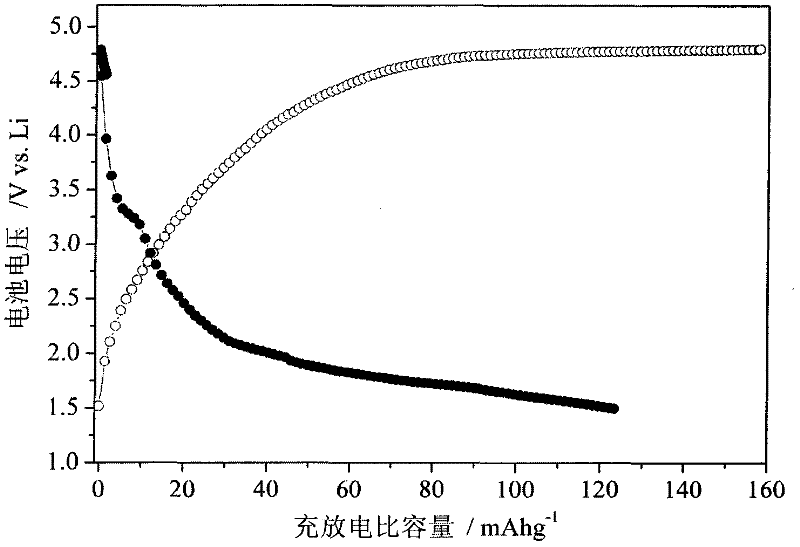

[0032] Weigh ferrous oxalate (4.66g), microsilica (3.41g), lithium carbonate (2.96g) and sucrose (7.10g) into a ball mill jar, ball mill and mix in absolute ethanol, then vacuum dry at 60°C A precursor mixture is obtained. The precursor is pressed into tablets, pre-calcined at 400°C for 3 hours in nitrogen, and then roasted at 750°C for 8 hours. During the solid-state reaction at high temperature, the ferric iron is reduced to ferrous iron by carbon (the carbon is sucrose pyrolysis carbon or the carbon contained in microsilica powder), to obtain Li 2 FeSiO 4 / C composite cathode material. Assemble the button battery according to the method described in Example 1, and under the charge and discharge voltage range of 1.5 ~ 4.8V, the discharge specific capacity measured when it is charged and discharged at 0.1C, 0.5C and 1C is 134.30mAh / g, 122.30mAh / g, 103.80mAh / g. The SEM images of the prepared samples are shown in figure 1 , see the cycle curve at 1C figure 2 , see the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com