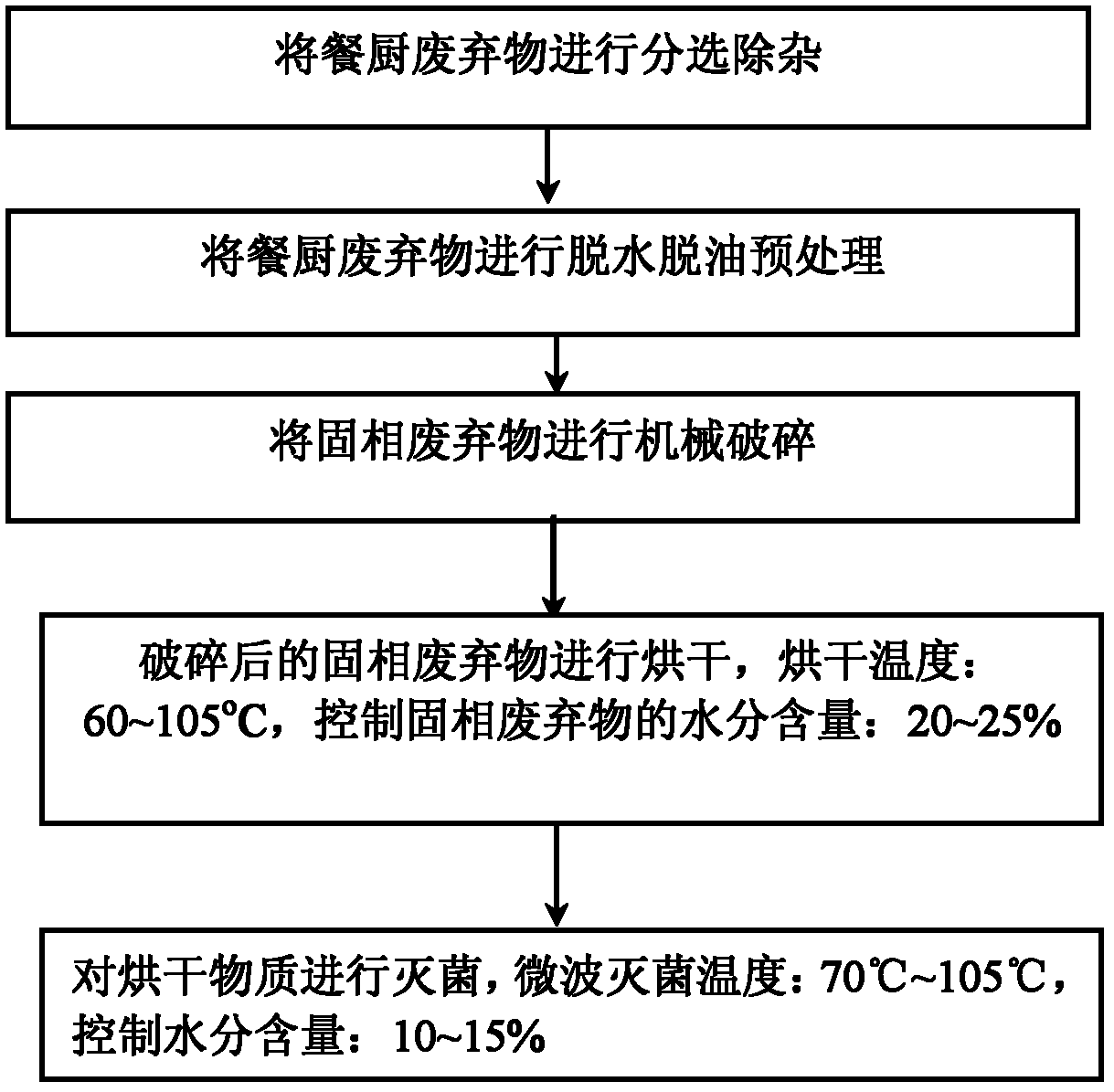

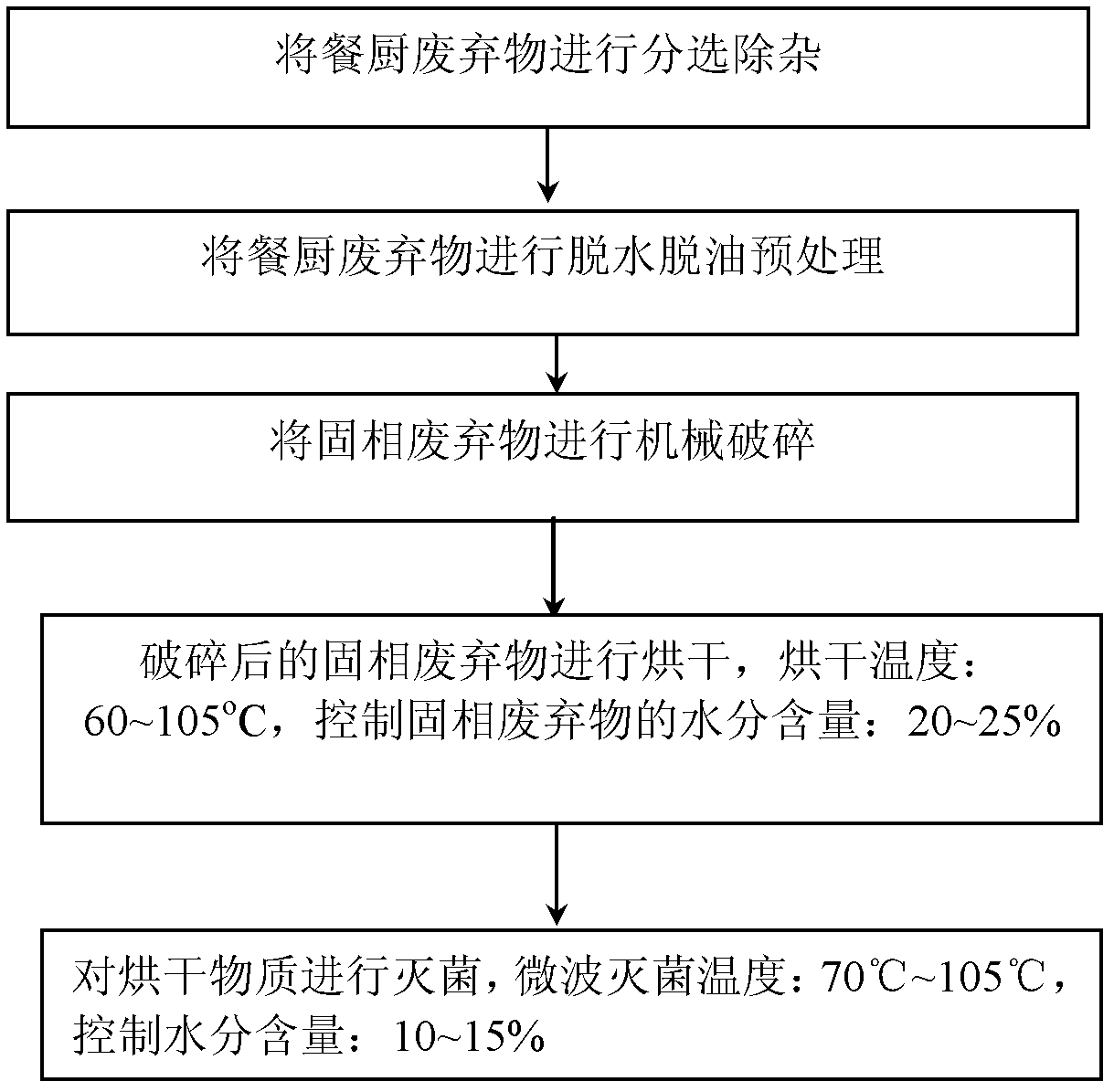

Method for preparing feed additive by using table and kitchen waste

A technology for adding kitchen waste and feed, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of high energy consumption and complex treatment methods, and achieve the effects of low energy consumption, significant economic benefits, and reduced consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Collect 50kg of kitchen waste (starch, protein, cellulose, lipids), the protein content after testing: 23.6%, after the collection process is manually sorted and managed to remove foreign objects, such as: plastic, iron parts, big bones, paper scraps, etc. , using mechanical dehydration equipment for dehydration pretreatment, so that the waste contains about 90% water and 15% oil. Put the pretreated material into the crusher to crush it. The crushed particle size is 40mm. The crushed material is transported to the belt drying system and dried at a drying temperature of 105°C for 4 hours until the moisture content is 20. %. Finally, microwave sterilization equipment was used for sterilization treatment. The sterilization temperature was 80°C for about 10 minutes to obtain feed additives. The moisture content was controlled at 10%, the protein content of the product was 22.7%, and the protein loss rate was 3.81%.

Embodiment 2

[0063] Collect 50kg of kitchen waste (starch, protein, cellulose, lipids), the protein content after testing: 23.6%, after the collection process is manually sorted and managed to remove foreign objects, such as: plastic, iron parts, big bones, paper scraps, etc. , using mechanical dehydration equipment for dehydration pretreatment, so that the waste contains about 90% water and 15% oil. Put the pretreated material into the crusher to crush it, the crushing particle size is 20mm, and then soak it in the sodium chloride salt solution, the concentration is 5‰ sodium chloride salt solution, the weight of the sodium chloride salt solution is the same as the solid waste Part ratio: 1:6, soak for 10 minutes, the upper oil layer part is separated and removed through the oil layer overflow system, the lower layer water and solid phase substances are dehydrated by belt filter press until the water content is about 65%. The belt speed is set at 12m / min, and the material that has passed ...

Embodiment 3

[0065] Take 50kg of kitchen waste (starch, protein, cellulose, lipids), the protein content after testing: 24.1%, after manual selection, remove foreign matter, such as: plastics, iron pieces, etc., and use mechanical dehydration equipment to dehydrate it. Treat the waste so that the waste contains about 80% water and about 8% oil. Put the pretreated material into the crusher to crush it, the crushing particle size is 50mm, add sodium chloride salt solution for soaking, its concentration is 2‰ sodium chloride salt solution, the weight part of sodium chloride salt solution is the same as solid waste Ratio: 1:4, soak for 15 minutes. The water content is reduced to 75% through the dehydration of the belt filter press. The belt speed of the belt filter press is 5m / min. The material that has passed the belt filter press is transported to the belt drying system and dried at 70°C. 7h, until the moisture content is 22%. Finally, microwave sterilization equipment was used to steriliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com