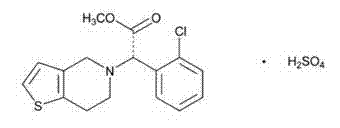

Clopidogrel bisulfate medicine composition and preparation method

A technology of clopidogrel bisulfate and composition, which is applied in the field of clopidogrel bisulfate pharmaceutical composition and preparation, can solve the problems of inability to wet granulate, high production cost, complicated operation, etc., achieve cheap excipients, and solve sticky punching Problems, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation process of clopidogrel bisulfate tablet

[0026] Group ratio:

[0027] Name of raw material 1000 tablets dosage Clopidogrel bisulfate 97.9g microcrystalline cellulose 120g Crospovidone 7.5g Glyceryl behenate 5g talcum powder 7.5g

[0028] Preparation:

[0029] (1) Crush the clopidogrel bisulfate, pass through an 80-mesh sieve, and set aside.

[0030] (2) Pass the microcrystalline cellulose through an 80-mesh sieve, and dry at 105°C for 2 hours for later use.

[0031] (3) Mix the above clopidogrel hydrogen sulfate and microcrystalline cellulose evenly, add an appropriate amount of ethanol solution to granulate.

[0032] (4) Dry the wet granules prepared above at 50°C, and control the moisture content of the granules below 3%.

[0033] (5) Sieve the dry granules for granulation, add croscarmellose sodium, glyceryl behenate, and talcum powder at the same time, mix evenly, and select a suitable ...

Embodiment 2

[0034] Embodiment 2: the preparation process of clopidogrel bisulfate tablet

[0035] Group ratio:

[0036] Name of raw material 1000 tablets dosage Clopidogrel bisulfate 97.9g microcrystalline cellulose 250g Crospovidone 30g Glyceryl behenate 4g talcum powder 4.5g

[0037] Preparation:

[0038] (1) Crush clopidogrel hydrogen sulfate, pass through a 200-mesh sieve, and set aside.

[0039] (2) Pass the microcrystalline cellulose through an 80-mesh sieve, and dry at 105°C for 2 hours for later use.

[0040] (3) Mix the above clopidogrel hydrogen sulfate and microcrystalline cellulose evenly, add an appropriate amount of ethanol solution to granulate.

[0041] (4) Dry the wet granules prepared above at 50°C, and control the moisture content of the granules below 3%.

[0042] (5) Sieve the dry granules for granulation, add croscarmellose sodium, glyceryl behenate, and talcum powder at the same time, mix evenly, and select a suitabl...

Embodiment 3

[0043] Embodiment 3: the preparation process of clopidogrel bisulfate tablet

[0044] Group ratio:

[0045] Name of raw material 1000 tablets dosage Clopidogrel bisulfate 97.9g microcrystalline cellulose 65g Crospovidone 5g Glyceryl behenate 2g talcum powder 3g

[0046] Preparation:

[0047] (1) Crush clopidogrel hydrogen sulfate, pass through a 200-mesh sieve, and set aside.

[0048] (2) Pass Starch 1500 through an 80-mesh sieve, and dry at 105°C for 2 hours for later use.

[0049] (3) Mix the above clopidogrel hydrogen sulfate and microcrystalline cellulose evenly, add an appropriate amount of ethanol solution to granulate.

[0050] (4) Dry the wet granules prepared above at 50°C, and control the moisture content of the granules below 3%.

[0051] (5) Sieve the dry granules for granulation, add crospovidone, glyceryl behenate, and talcum powder at the same time, mix evenly, and select a suitable pressure for tableting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com