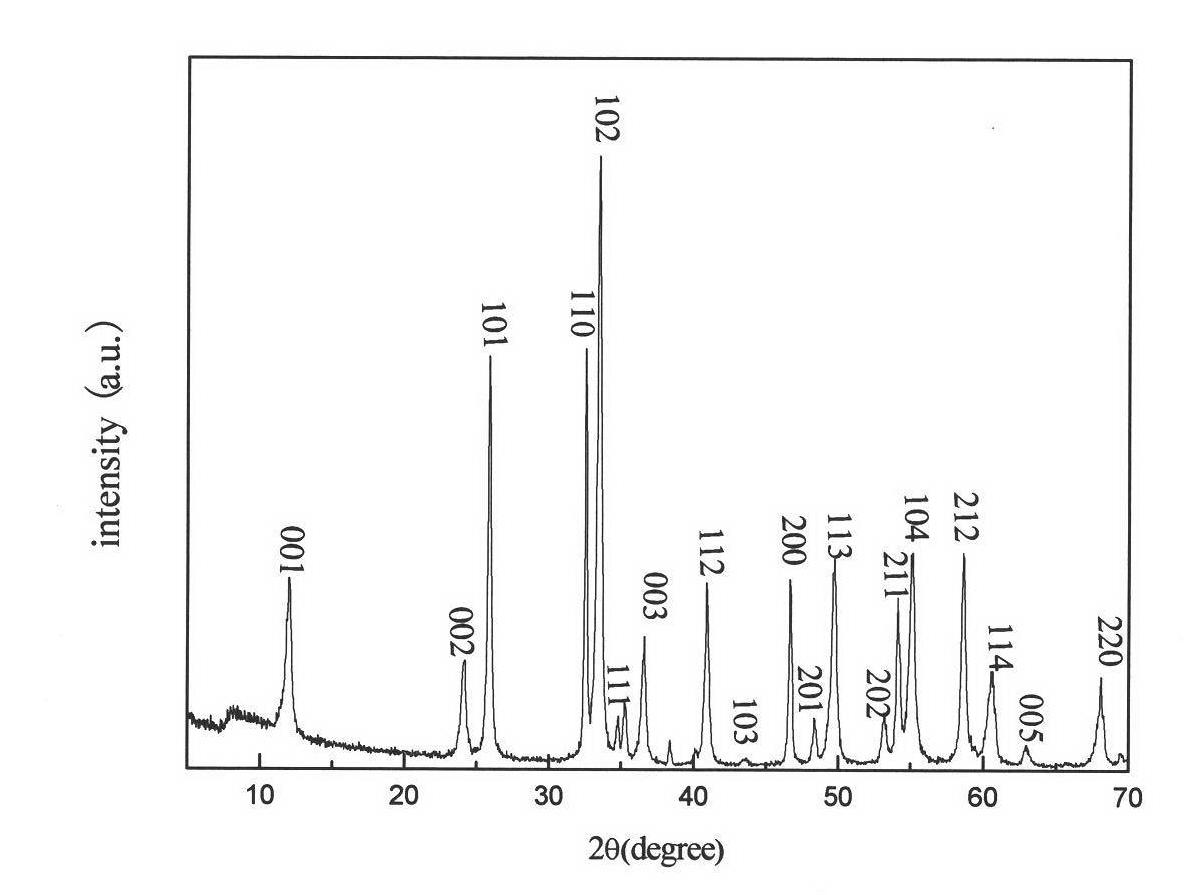

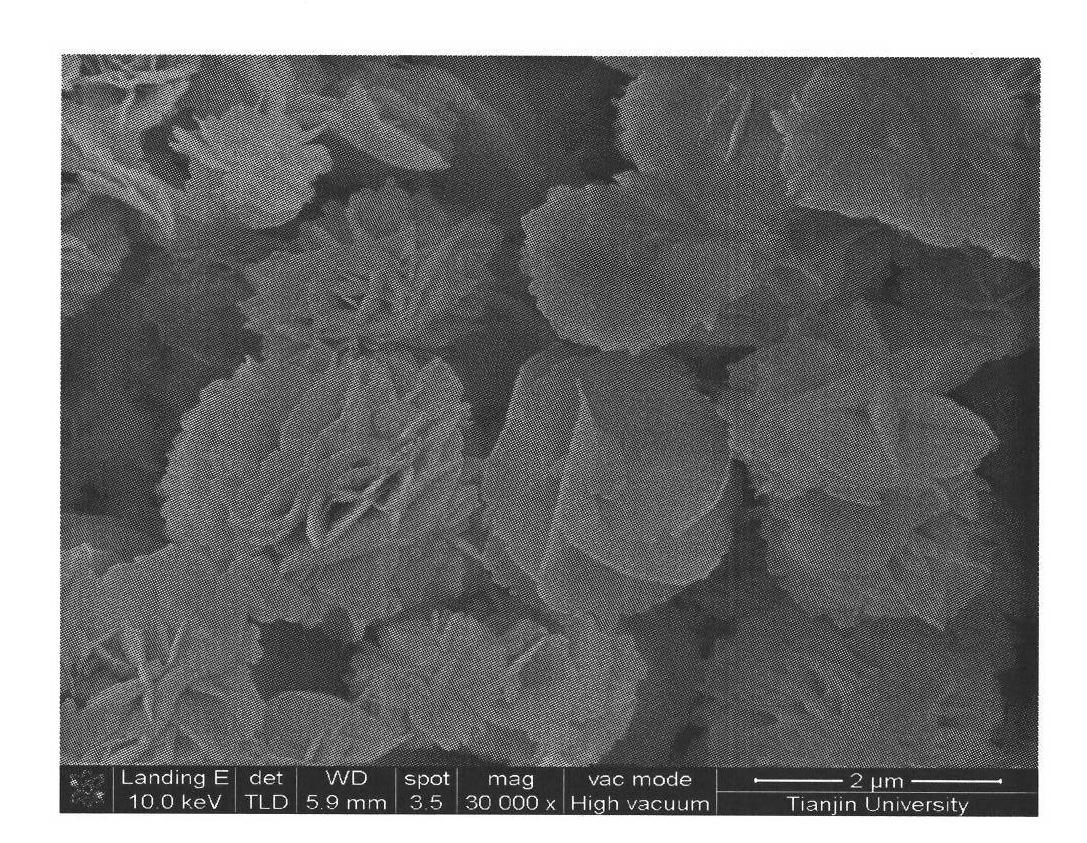

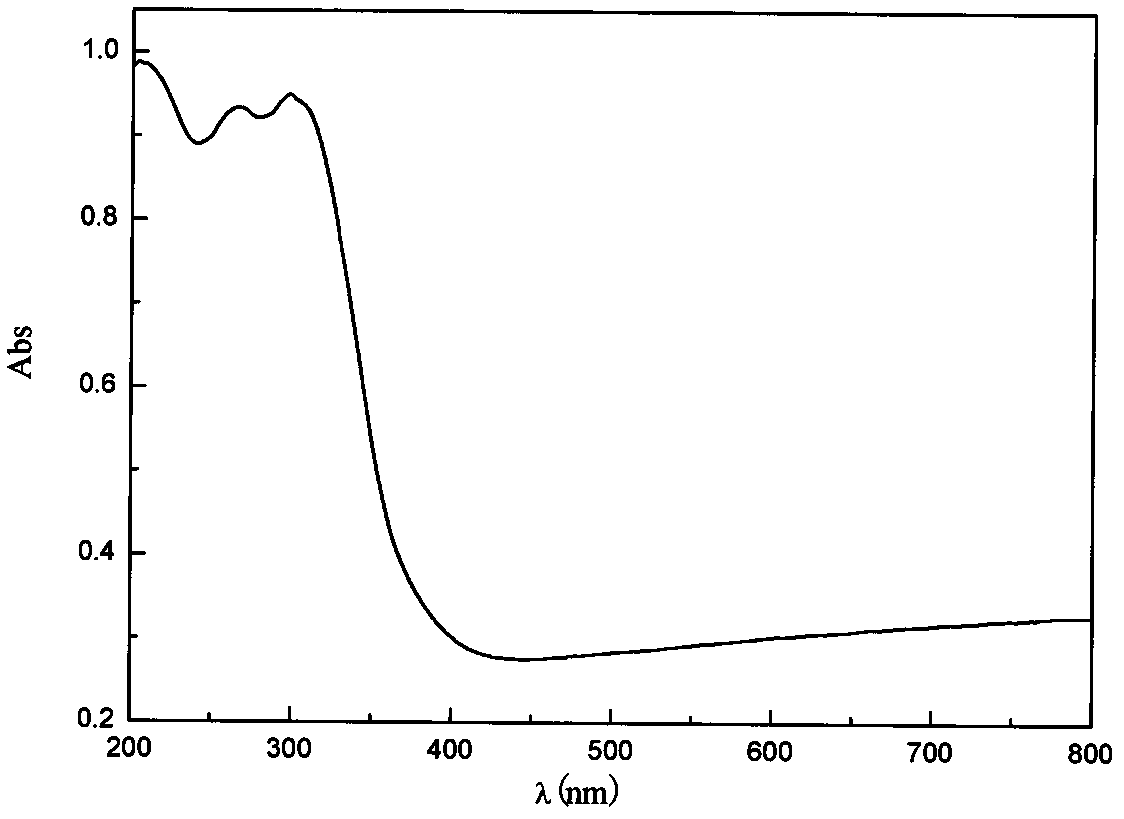

Preparation method of flower ball-shaped micro-nano film photocatalytic material

A photocatalytic material, flower ball-shaped technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult recovery, poor dispersibility, difficult separation of solutions, etc., and achieve convenient recovery. Utilization, good photocatalytic activity, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] 1) Weigh 0.2 g of analytically pure BiCl 3 Place it in 10mL of ethylene glycol, heat to 60°C, stir to dissolve;

[0021] 2) Use 25%-28% ammonia water to adjust the pH value of the solution to 9, and react for 1 hour to obtain a white emulsion, which is the precursor solution;

[0022] 3) Coat the precursor solution prepared in step 2) on the titanium plate substrate with a clean surface, then place it in an oven at 80°C for drying, then repeat the coating and drying for 30 times, and finally place it at 80°C Dry it in an oven for 3 hours, take it out and soak it in distilled water for cleaning, and then the flower-shaped micro-nano BiOCl thin film photocatalytic material is obtained.

[0023] The prepared film is used for photocatalytic degradation of methyl orange in water. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, take the prepared film 1 cm × 6 cm as the photocatalyst, and blow air from the bottom ...

Embodiment approach 2

[0025] 1) Weigh 0.4 grams of analytically pure BiCl 3 Place it in 20mL of ethylene glycol, heat to 80°C, stir to dissolve;

[0026] 2) Use 25%-28% ammonia water to adjust the pH value of the solution to 7, and react for 1.5 hours to obtain a white emulsion, which is the precursor solution;

[0027] 3) Coat the precursor solution prepared in step 2) on the titanium substrate with a clean surface, then place it in an oven at 75°C for drying, then repeat the coating and drying for 15 times, and finally place it at 75°C Dry it in an oven for 3 hours, take it out and soak it in distilled water for cleaning, and then the flower-shaped micro-nano BiOCl thin film photocatalytic material is obtained.

[0028] The prepared film is used for photocatalytic degradation of methyl orange in water. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, take the prepared film 1 cm × 6 cm as the photocatalyst, and blow air from the bottom...

Embodiment approach 3

[0030] 1) Weigh 0.8 grams of analytically pure BiCl 3 Place it in 40mL of propylene glycol, heat to 80°C, and stir to dissolve it.

[0031] 2) Using ammonia water to adjust the pH value of the solution to 7, and reacting for 2 hours to obtain a white emulsion.

[0032] 3) Apply the emulsion prepared in step 2) to the substrate with a clean surface, and apply it 25 times. After each application, put it in an oven at 80°C to dry and then continue to apply. After all the precursor solution was coated on the substrate, it was dried for 2.5 hours, soaked and cleaned, and the curd-shaped micro-nano BiOCl thin film photocatalytic material was prepared.

[0033] The prepared film is used for photocatalytic degradation of methyl orange in water. The reaction conditions are: normal temperature and pressure, 50 mL of 10 mg / L methyl orange aqueous solution, take the prepared film 1 cm × 6 cm as the photocatalyst, and blow air from the bottom of the reactor , Sampling and analysis at reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com