Sol-gel preparation method of strontium titanate lead thin film

A strontium lead titanate and sol-gel technology, which is applied in the field of preparation of functional dielectric films, can solve the problems of long storage time and poor dielectric tuning performance, and achieve the effects of high preparation efficiency, inhibition of hydrolysis, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: No miscellaneous strontium titanate lead Pb 0.3 Sr 0.7 TiO 3 Sol preparation

[0020] 7.51g of strontium acetate [Sr(CH 3 COO) 2 ] and 5.97g of lead acetate trihydrate [ Pb(CH 3 COO) 2 ·3H 2 O] dissolve the mixed solution of deionized water and glacial acetic acid to obtain solution A; then dissolve the tetrabutyl titanate of 17.5g in ethylene glycol methyl ether, stir and mix evenly to obtain solution B; pour solution B into In solution A, add acetylacetone, formamide and glycerol in a volume ratio of 2~4:1.4~2.2:1.5~2.1 in sequence, stir evenly, heat to 90°C for 1 hour, and filter to obtain a clear and transparent precursor body sol. like figure 1 The strontium lead titanate sol stored for 3 months is still clear and transparent.

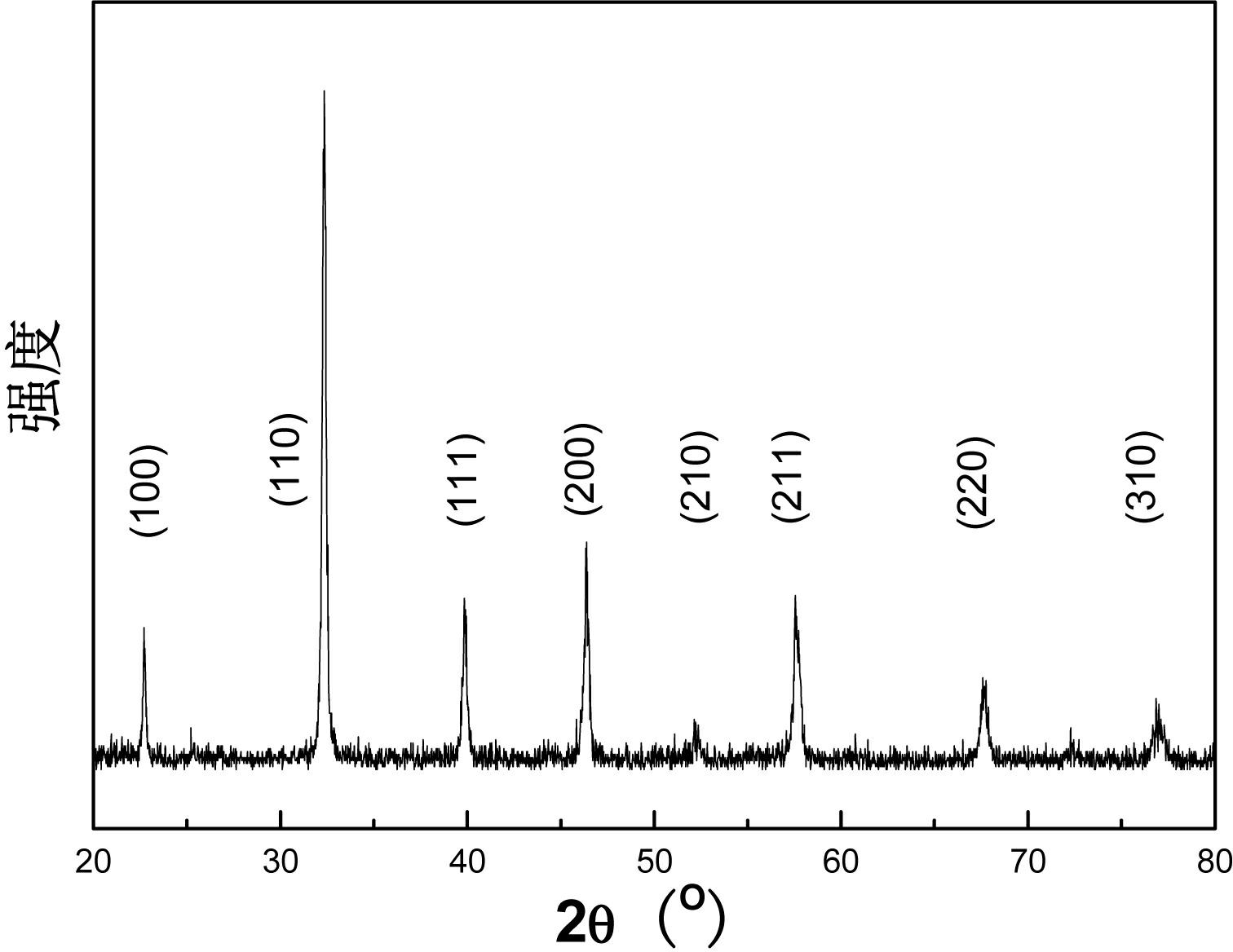

[0021] Pour a small amount of strontium lead titanate Pb 0.3 Sr 0.7 TiO 3 The sol was put into a dry pot and calcined at 750°C for 1 hour to obtain a white powder. Use XRD to do the phase test of the powder, suc...

Embodiment 2

[0022] Embodiment 2: lead strontium titanate Pb 0.3 Sr 0.7 TiO 3 thin film preparation and its dielectric tuning properties

[0023] The prepared Pb 0.3 Sr 0.7 TiO 3 After the precursor sol was aged for 1~2 weeks, the Pt / Ti / SiO 2 / Si substrate was prepared by spin-coating at a speed of 4000 rpm for 25 seconds; then the coated film was annealed at 700°C for 0.5h; the process of "spin coating-annealing" was repeated several times to obtain the desired thickness of strontium lead titanate film.

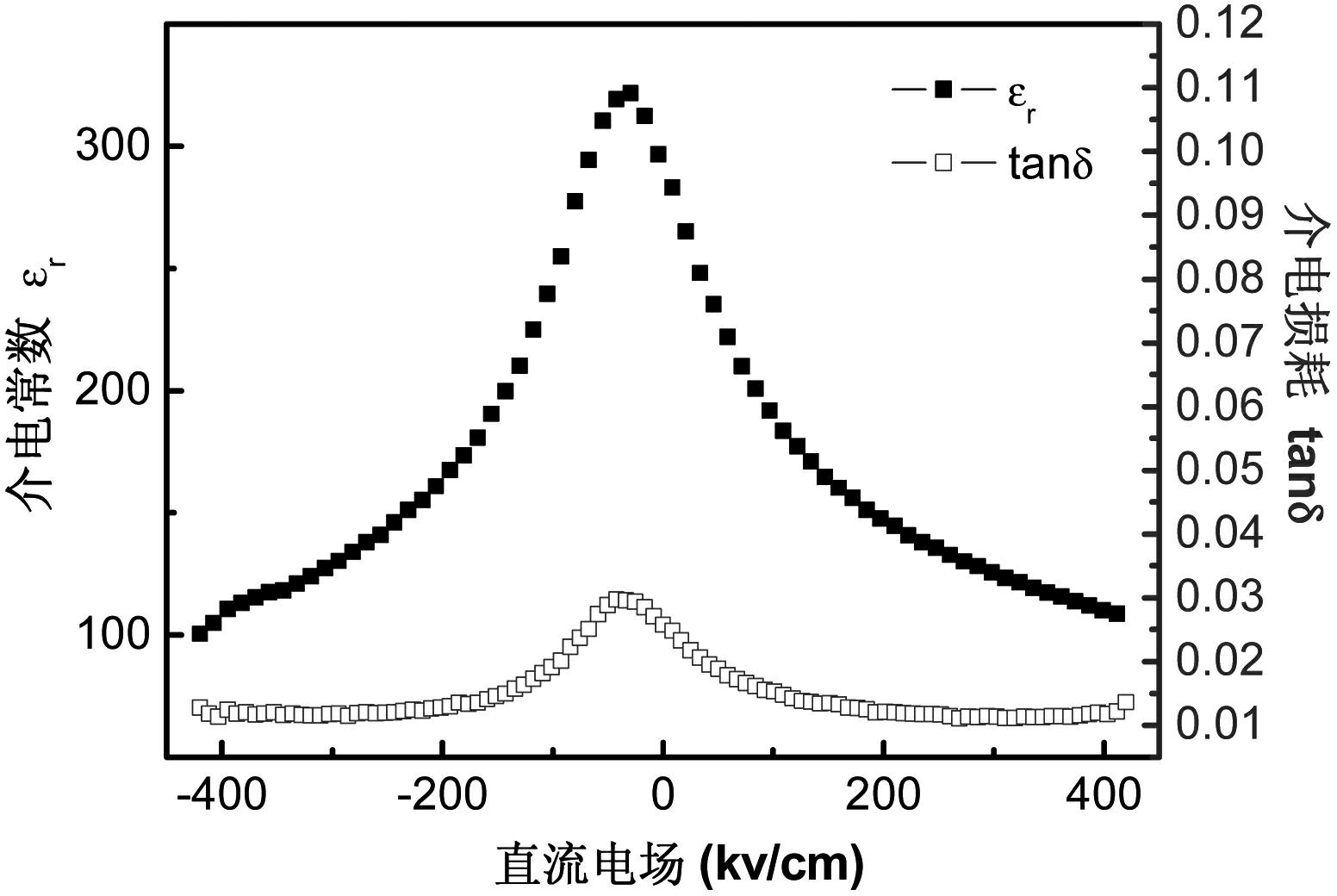

[0024] Using magnetron sputtering equipment on Pt / Ti / SiO 2 / Pb on Si substrate 0.3 Sr 0.7 TiO 3 The Au top electrode was prepared on the film to form a plate capacitor, and the dielectric tuning performance was tested with Aginengt 4294A. like image 3 As shown, the film has excellent dielectric tuning performance: the tuning amount is 66.4%, and the dielectric loss is 0.029.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com