Harmless treatment process for acidic copper-containing wastewater

A technology for harmless treatment of acidic wastewater, applied in multi-stage water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as ion accumulation effects that are not considered, and achieve resource recovery , Conducive to the effect of environmental governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

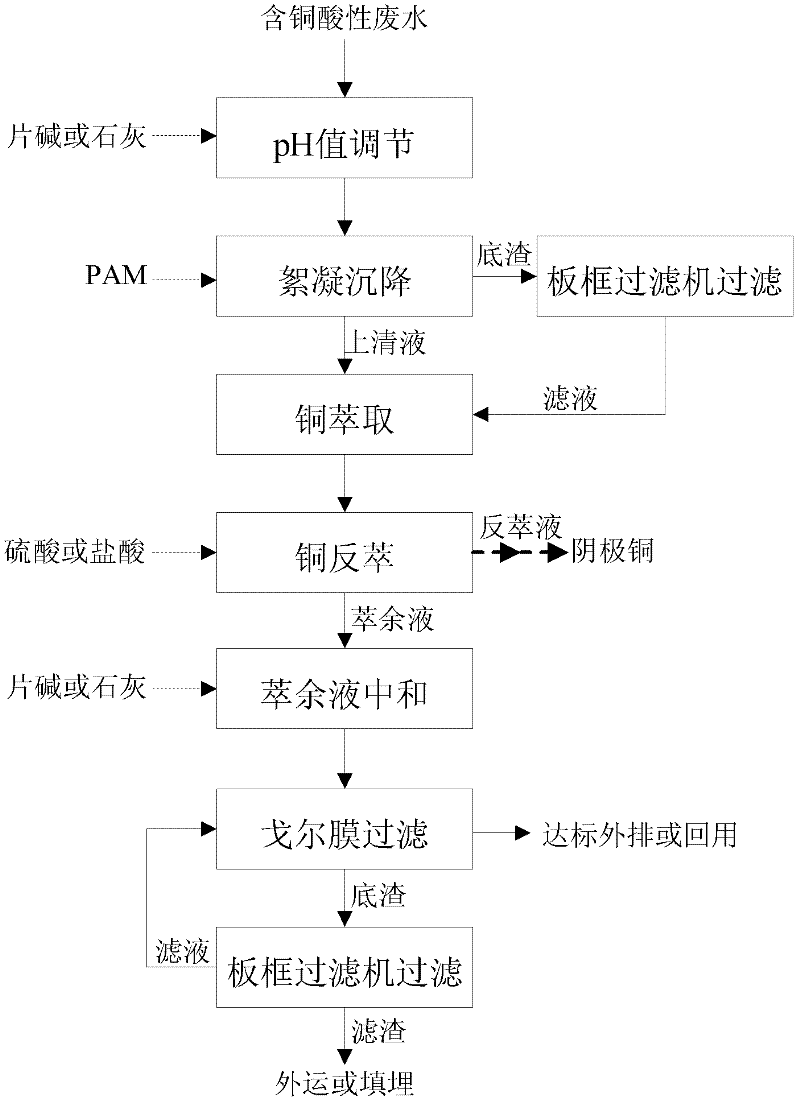

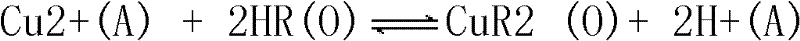

Method used

Image

Examples

Embodiment 1

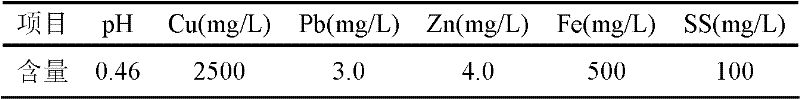

[0034] Example 1: A gold smelting factory in Fujian, using gold-loaded carbon as raw material, processes and produces standard gold ingots, degolded carbon and other products, adopts cyanide-free desorption electrowinning, wet extraction combined refining, and wet-fired regeneration of degolded carbon and silver electrolysis production process. A copper-containing acidic wastewater is produced during the production process, the wastewater volume is 1m3 / hr, and the wastewater quality is shown in Table 1.

[0035] Table 1 Water quality analysis results of acidic wastewater containing copper in a gold smelter in Fujian

[0036]

[0037] Adopt process of the present invention to process:

[0038] The first step: the adjustment process of wastewater pH value. Add caustic soda 2.6kg / m3, stir in the air for about 30 minutes, and the pH value is about 1.5;

[0039] The second step: the solid-liquid separation process of the neutralizing liquid. Pre-prepared PAM solution with a ...

Embodiment 2

[0050] Carry out embodiment 1 repeatedly by above-mentioned identical steps, but difference is that the first step regulates waste water pH value to 2.2 and used alkali is lime, and in the 3rd step, extraction agent volume concentration is 5% (ZJ988, hydroxyketoxime and The compound of aldoxime, volume concentration is 5%, diluent 260# kerosene, volume concentration is 95%), other various technical parameters and steps are identical with embodiment 1.

[0051] Embodiment 2 After being processed by the above-mentioned method, the consumption of lime in the first step is 6.8kg / m3; In the third step, the water quality analysis results of raffinate and stripping liquid are shown in Table 4; in the fourth step, the amount of lime added The water volume is about 18.3kg / m3, the pH value of the water body is 8.03, and the suspended solids content is 583mg / L; in the fifth step, the dry rate of the bottom slag in Gore membrane filtration is 17.96%, and the volume of effluent and bottom s...

Embodiment 3

[0058] Repeat Example 1 according to the same steps above, but the difference is that the fifth step Gore membrane filtration process conditions are changed to: filtration time 300s, liquid inlet time 700s, exhaust time 7s, pressure increase and release time 7s, recoil The time is 30s, the number of slagging cycles is 7 times, the pre-discharging time is 90s, the settling time is 50s, and the slagging time is 6s; other technical parameters and steps are the same as in Example 1.

[0059] Example 3 After being treated by the above method, the copper extraction rate and the copper content of the stripping solution are the same as those in Example 1, but in the fifth step, the dry rate of the bottom slag filtered by the Gore membrane is 15.8%, and the volume of the effluent and the bottom slag is 99:1 , the water quality analysis of the effluent is shown in Table 6; in the sixth step, the drying rate of the filter residue of the plate and frame filter press is 37.2%.

[0060] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com