Treatment method for wastewater in adipic acid production

A technology for producing wastewater and adipic acid, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of reducing the dosage and energy consumption, controlling the operation and processing costs, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

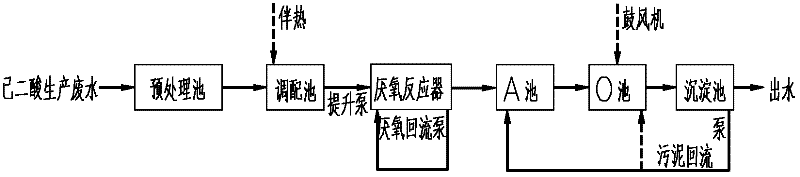

[0018] The steps of the present invention are:

[0019] (1) Pretreatment: Adjust the raw water (pH is about 1) to about pH=6.2, and use iron salt + PAM for coagulation and sedimentation; the effluent is sent to the deployment pool, supplemented with trace elements and inorganic phosphorus sources, so that the nutrient ratio meets COD Cr : P=200-300: 1, now the carbon-nitrogen ratio (COD / TN) of waste water is 3~5;

[0020] (2) Anaerobic treatment: send the pre-treated adipic acid production wastewater into the anaerobic reactor, control the water temperature at 35°C±2.5°C, and the concentration of VFA is less than 10mmol / L; the three phases are separated by adjusting the pH of the influent The pH of the effluent at the device is 8.0-8.5; the organic load of the influent is greater than 2.5kgCOD / m 3 d, the residence time is more than 30h, and the internal reflux flow is controlled so that the rising flow rate is not less than 1.0m / h; 80% of TN in the wastewater is removed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com