Rapid air-drying method of residual activated sludge

A technology of residual active and activated sludge, applied in dehydration/drying/concentrated sludge treatment, energy wastewater treatment, etc., can solve the problems of high water content in activated sludge, which cannot be directly used, and cannot meet the ideal needs. Achieve the effects of increased drying speed, easy operation, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Put 10kg of activated sludge with a water content of 82% after mechanical dehydration into a 25L barrel, add 1.5L of 5% milk of lime to prepare a flowable slurry, put it in the reaction tank for 24 hours overnight, and wait for the remaining active sludge After the parasite eggs in the mud are killed and the water in the living body is fully seeped, add 0.5kg of peanut shell powder, stir the remaining activated sludge into a distiller's yeast shape, and then spread it on the bottom of the air-drying box with a thickness of 20cm. The two ends of the box are respectively provided with a blower port and an air outlet, and a threaded stirring rod is installed at a distance of 5cm from the bottom of the box. - 3 times / min, the stirring speed is 2 rev / min. After air drying for 48 hours, the water content of the sludge was 39%; after 72 hours, the water content of the sludge was 31%.

Embodiment 2-5

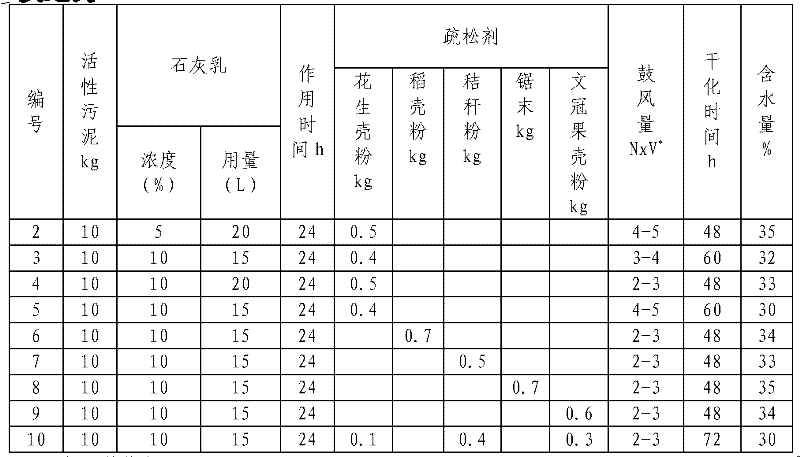

[0017]

[0018] V * : Air-drying box volume

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com