High-performance potassium sodium niobate-based leadless piezoelectric ceramic and preparation method for same

A potassium sodium niobate-based, lead-free piezoelectric technology, applied in the field of functional ceramic materials, can solve the problems of inability to approach or achieve performance, unstable comprehensive performance, unsatisfactory material performance, etc., and achieve important practical significance and social benefits, Performance and stability, the effect of improving piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

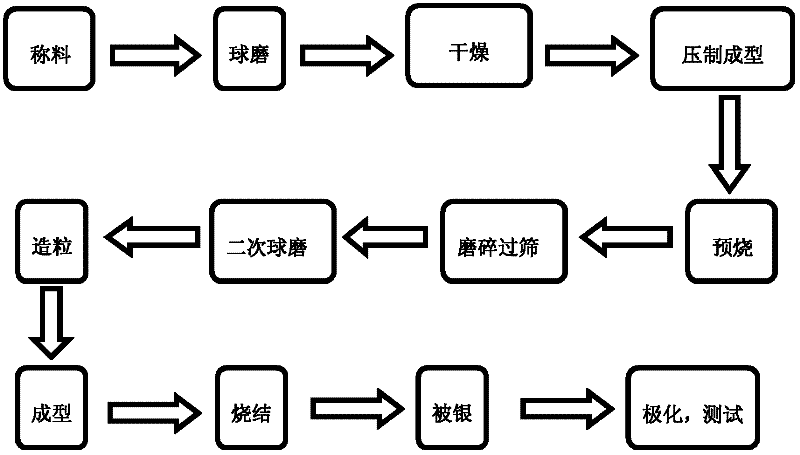

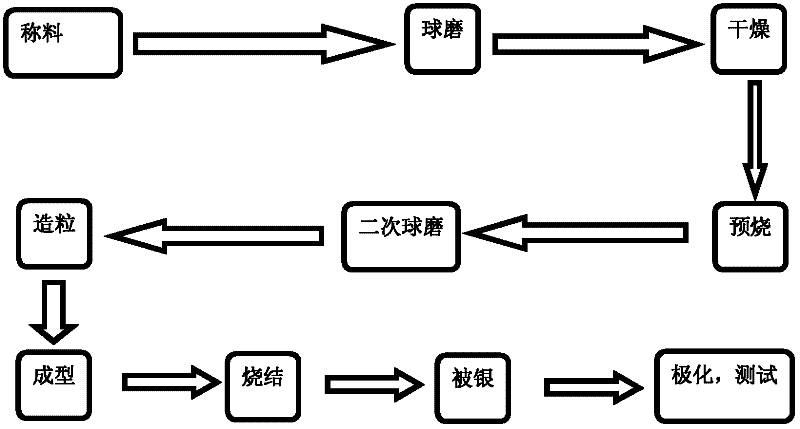

[0031] Such as figure 1 As shown, the preparation method of high-performance potassium sodium niobate-based lead-free piezoelectric ceramics in this embodiment is as follows:

[0032] (1) Preparation of potassium sodium niobate-based lead-free piezoelectric ceramic pre-fired green body

[0033] (1-1) the carbonate of K, Na, Li, the oxide compound of Nb, Sb, Ta are weighed batching according to the parameter shown in Table 1;

[0034] (1-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 14 hours, and obtain the mixed powder after drying;

[0035](1-3) Press the mixed powder into a large piece with a diameter of 20mm and a thickness of 5mm under a pressure of 10MPa, and then pre-fire it in the air at 800, 850, 900, 950, and 1000°C respectively, keep it warm for 6 hours, and Cooling obtains the sodium potassium niobate base calcined block;

[0036] (1-4) Grinding the potassium-sodium niobate-based calcined block t...

Embodiment 2

[0047] Such as figure 1 As shown, the preparation method of high-performance potassium sodium niobate-based lead-free piezoelectric ceramics in this embodiment is as follows:

[0048] (1) Preparation of potassium sodium niobate-based lead-free piezoelectric ceramic pre-fired green body

[0049] (1-1) with the carbonate of K, Na, Li, Ba, the oxide compound of Nb, Sb, Ta, Zr takes batching according to the parameter shown in Table 1;

[0050] (1-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 20 hours, and obtain the mixed powder after drying;

[0051] (1-3) Press the mixed powder into a large sheet with a diameter of 30 mm and a thickness of 8 mm under a pressure of 11 MPa, and then pre-fire it in the air at 800, 850, 900, 950, and 1000 °C respectively, keep it warm for 4 hours, and then Furnace cooling obtains potassium sodium niobate base calcined block;

[0052] (1-4) Grinding the potassium-sodium niobate-b...

Embodiment 3

[0063] Such as figure 1 As shown, the preparation method of high-performance potassium sodium niobate-based lead-free piezoelectric ceramics in this embodiment is as follows:

[0064] (1) Preparation of potassium sodium niobate-based lead-free piezoelectric ceramic pre-fired green body

[0065] (1-1) with the carbonate of K, Na, Li, Ba, the oxide compound of Nb, Sb, Ta, Zr takes batching according to the parameter shown in Table 1;

[0066] (1-2) Add the prepared raw materials into a ball mill with absolute ethanol as the medium, ball mill the mixture for 18 hours, and obtain the mixed powder after drying;

[0067] (1-3) Press the mixed powder into a large sheet with a diameter of 20 mm and a thickness of 5 mm under a pressure of 14 MPa, and then pre-fire it in the air at a temperature of 900 ° C, keep it for 6 hours, and cool it with the furnace to obtain a potassium-sodium niobate-based pre-calcined burning block;

[0068] (1-4) Grinding the potassium-sodium niobate-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com