Synthesis method of food grade modified foaming agent azodicarbonamide

A technology of azodicarbonamide and a synthesis method, applied in the field of azodicarbonamide synthesis, can solve the problem of affecting the quality of "AC" foaming agent, difficult to remove highly toxic chemical impurities, and difficult to purify and remove oxidative impurities and other problems, to achieve the effect of low requirements for reaction equipment, less impurities and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

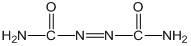

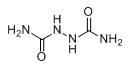

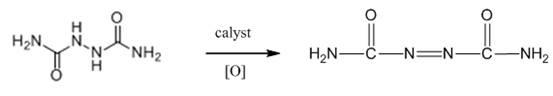

Image

Examples

Embodiment 1

[0026] The carrier macromolecular compound in the cerium composite catalyst contains the macromolecular silicate of alkylsulfonic acid group and is prepared by the following method: get 125g of potassium dodecylsulfonate, 200g of sodium silicate, and 2.5g of zinc bromide and mix them evenly. Add 800mL of deionized water and stir for 48 hours, then add 6.5g of manganese dioxide (powder, particle size 300 mesh) and mix well, then let it stand still, remove the water layer to get a jelly, let the jelly deposit into a block, and let it dry naturally , and then calcined in a muffle furnace at a high temperature of 850°C to prepare a macromolecular silicate containing an alkylsulfonic acid group.

[0027] Take 200g of the above-mentioned macromolecular silicate and 5.0g of cerium oxide, add it to 200mL of 18% sulfuric acid, soak at 45°C for 12 hours, filter and wash twice with dilute sulfuric acid with a pH of 2.5 to prepare the cerium composite catalyst.

[0028] In a 1000ml three-...

Embodiment 2

[0030] The carrier macromolecular compound in the cerium composite catalyst contains alkylsulfonic acid group-containing macromolecular silicate and is prepared by the following method: Take 100 g of potassium dodecyl sulfonate, 200 g of sodium silicate, and 2 g of zinc bromide, mix well, add 610mL of deionized water was fully stirred for 30 hours, then 5.5g of manganese dioxide (powder, particle size 300 mesh) was added and mixed thoroughly, then left to stand, the water layer was removed to obtain a jelly-like substance, and the jelly-like substance was allowed to settle into blocks, and then air-dried. Then in a muffle furnace, calcined at a high temperature of 650°C to prepare a macromolecular silicate containing an alkylsulfonic acid group.

[0031] Take 200g of the above-mentioned macromolecular silicate and 10g of cerium oxide, add it to 200mL of 18% sulfuric acid, soak at 45°C for 12 hours, filter and wash twice with dilute sulfuric acid with a pH of 2.5 to prepare the ...

Embodiment 3

[0034]The carrier macromolecular compound in the cerium composite catalyst contains the macromolecular silicate of alkylsulfonic acid group and is prepared by the following method: Take 150g of potassium dodecylsulfonate, 200g of sodium silicate, and 3g of zinc bromide, mix them evenly, add 1765mL of deionized water was fully stirred for 40 hours, then 12.7g of manganese dioxide (powder, particle size: 300 mesh) was added and mixed thoroughly, then left to stand, the water layer was removed to obtain a jelly, and the jelly was allowed to settle into blocks, and then air-dried. Then, in a muffle furnace, calcining at a high temperature of 1000° C. is prepared to obtain a macromolecular silicate containing an alkylsulfonic acid group.

[0035] Take 200g of the above-mentioned macromolecular silicate and 24g of cerium oxide, add it to 200mL of 18% sulfuric acid, soak at 45°C for 12 hours, filter and wash twice with dilute sulfuric acid with a pH of 2.5 to prepare the cerium compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com