Room-temperature self-crosslinkable styrene-acrylic emulsion resistant to ethanol dilution and preparation method for same

A styrene-acrylic emulsion and self-crosslinking technology, used in applications, inks, household appliances, etc., can solve the problem of limiting the application range of water-based inks, the production efficiency of water-based inks cannot reach the production efficiency of solvent-based inks, and the drying rate of water-based inks is difficult to further improve. and other problems, to achieve the effect of increasing the density of film formation, increasing the cross-linking density and improving the compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

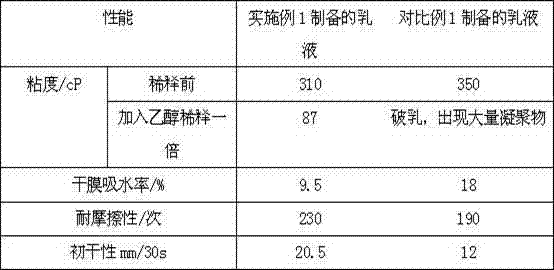

Examples

Embodiment 1

[0041] (1) Preparation of mixed monomer pre-emulsion: first add 7g methyl methacrylate, 15g butyl acrylate, 15g styrene, 1.2g acrylic acid, 7g octadecyl methacrylate into a container equipped with a mechanical stirring device Ester, 1.8g AAEM, 0.64g nonylphenol polyoxyethylene ether (Rhodia company NP-10), 0.53g solid content is 58% nonylphenol polyoxyethylene ether ammonium sulfate aqueous solution (Rhodia company CO- 436) and 20g of water, and then stirred at a speed of 500rpm for about 30min to obtain a mixed monomer pre-emulsion;

[0042] (2) Preparation of seed emulsion: Add 0.19g sodium bicarbonate, 0.25g nonylphenol polyoxyethylene ether (Rhodia NP-10), and 0.21g nonylphenol with a solid content of 58% to a four-neck flask Polyoxyethylene ether ammonium sulfate aqueous solution (Rhodia CO-436), 16.01g of water and part of the mixed monomer pre-emulsion (the specific mass is 6% of the mixed monomer pre-emulsion obtained in step (1)), heating up To 75°C, add 0.07g ammoni...

Embodiment 2

[0047] (1) Preparation of mixed monomer pre-emulsion: first add 12g methyl methacrylate, 6g butyl acrylate, 22g styrene, 1g acrylic acid, 5g octadecyl methacrylate into a container equipped with a mechanical stirring device , 1g AAEM, 0.64g nonylphenol polyoxyethylene ether (Rhodia NP-10), 0.53g solid content of 58% nonylphenol polyoxyethylene ether ammonium sulfate solution (Rhodia CO-436) and 20g of water, then stirred at a speed of 500rpm for about 30min to obtain a mixed monomer pre-emulsion;

[0048] (2) Preparation of seed emulsion: Add 0.19g sodium bicarbonate, 0.25g nonylphenol polyoxyethylene ether (Rhodia NP-10), and 0.21g nonylphenol with a solid content of 58% to a four-neck flask Polyoxyethylene ether ammonium sulfate aqueous solution (Rhodia CO-436), 16.36g of water and the above-mentioned mixed monomer pre-emulsion accounting for 6% of the total mass of the mixed monomer pre-emulsion, heated to 74°C, and added 0.07g Ammonium persulfate was reacted for 15 minute...

Embodiment 3

[0053] (1) Preparation of mixed monomer pre-emulsion: first add 10g methyl methacrylate, 7g butyl acrylate, 19g styrene, 1.2g methacrylic acid, 8g octadecyl acrylate to a container equipped with a mechanical stirring device Ester, 1.8g DAAM, 0.64g nonylphenol polyoxyethylene ether (Rhodia company NP-10), 0.53g solid content is 58% nonylphenol polyoxyethylene ether ammonium sulfate aqueous solution (Rhodia company CO- 436) and 20g of water, and then stirred at a speed of 500rpm for about 30min to obtain a mixed monomer pre-emulsion;

[0054] (2) Preparation of seed emulsion: Add 0.15g sodium bicarbonate, 0.29g nonylphenol polyoxyethylene ether (Rhodia NP-10), and 0.21g nonylphenol with a solid content of 58% to a four-neck flask Polyoxyethylene ether ammonium sulfate aqueous solution (Rhodia CO-436), 16g of water and the above-mentioned mixed monomer pre-emulsion accounting for 6% of the total mass of the mixed monomer pre-emulsion, the temperature was raised to 76°C, and 0.07g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com