Preparation method of blue dye

A blue dye and product technology, applied in the direction of azo dyes, organic dyes, complex metal compounds of azo dyes, etc., can solve the problems of low coupling yield, large waste water, high COD waste water, etc., to reduce the content of COD , reduce environmental pollution, and stabilize the diazo product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

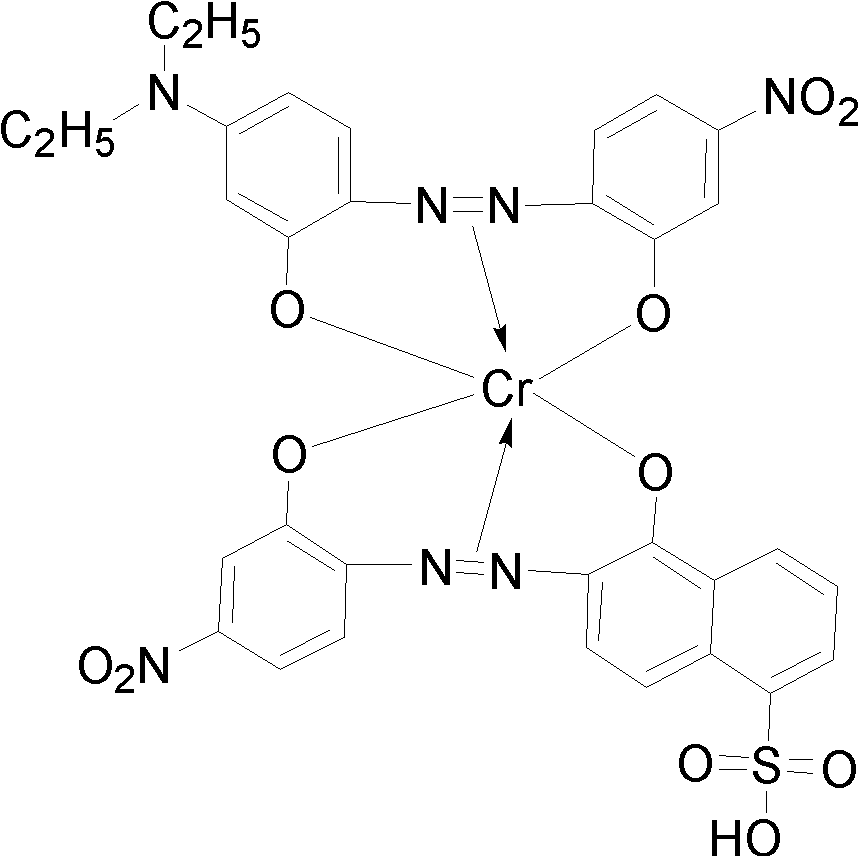

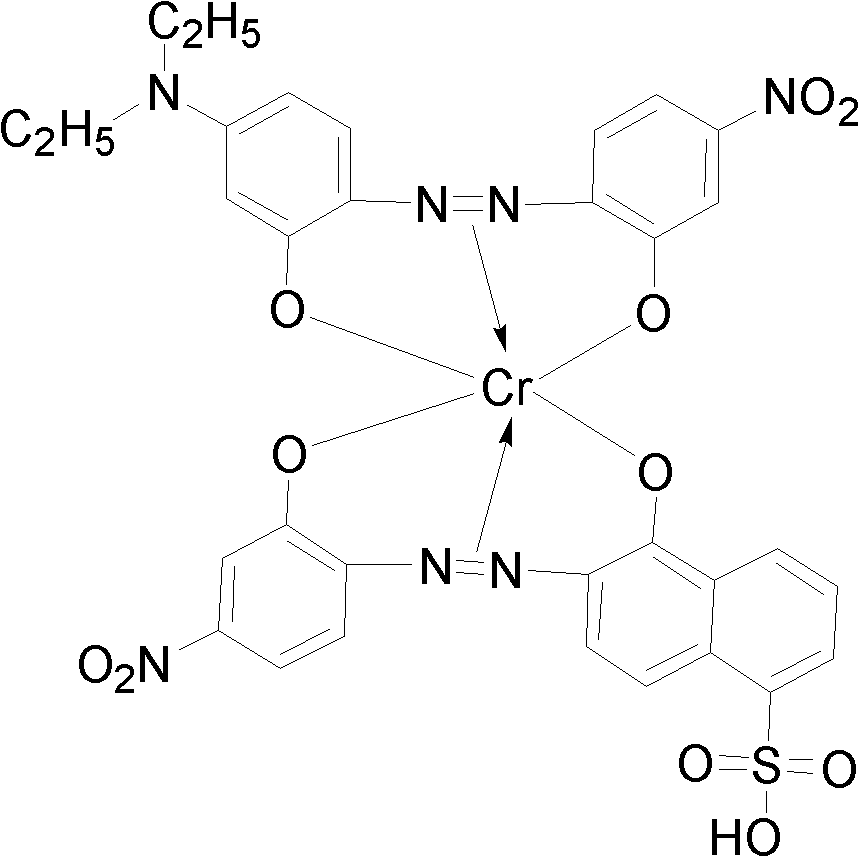

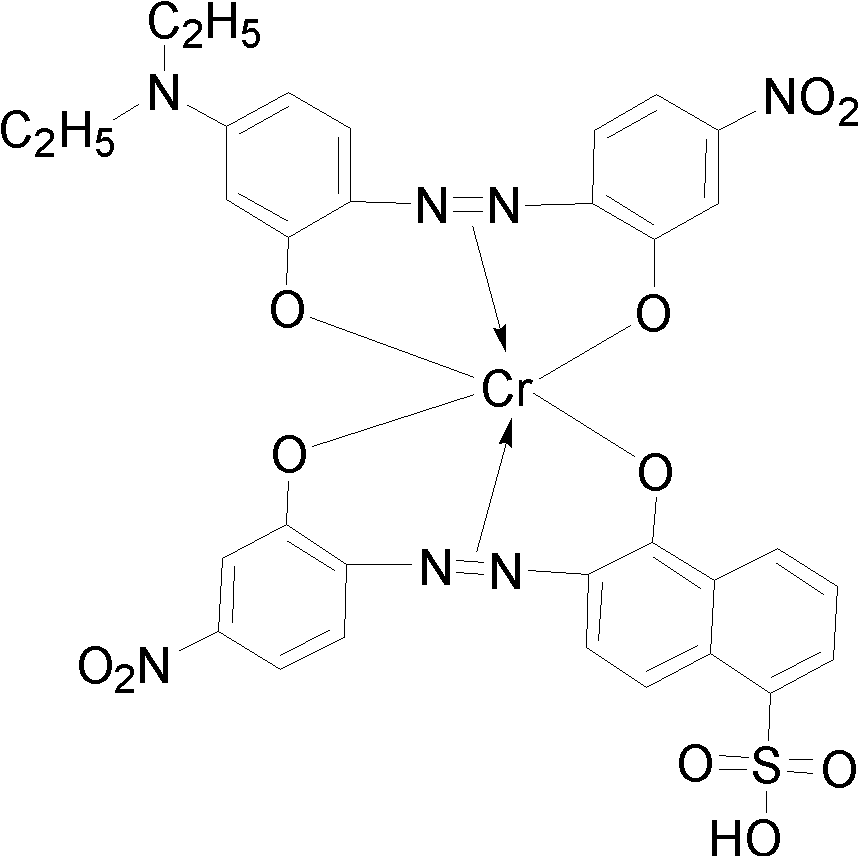

[0042] The invention provides a kind of preparation method of the blue dye shown in formula I, comprising:

[0043] a) Mix 2-amino-5-nitrophenol, hydrochloric acid and nitrous solution in ice water, and carry out the first diazotization reaction to obtain the first diazonium product;

[0044] b) performing the first coupling reaction on the first diazonium product obtained in step a), butanone, and 1-naphthol-5-sulfonic acid solution to obtain the first coupling product;

[0045] c) mixing 2-amino-5-nitrophenol, hydrochloric acid, and sodium nitrite in an ice-water bath, using potassium iodide for color development, and performing a second diazotization reaction to obtain a second diazonium product;

[0046] d) mixing the alkaline solution of N,N-diethyl-m-hydroxyaniline with the second diazonium product, and performing the second coupling reaction to obtain the second coupling product;

[0047] e) mixing the first coupling product with basic chromium sulfate, salicylic acid, a...

Embodiment 1

[0090] a. Dissolution suction filtration of 1-naphthol-5-sulfonic acid and N,N-diethyl-m-hydroxyaniline

[0091] Add 2040L of water into the reaction kettle, adjust the temperature to 25°C, add 352.2Kg of 1-naphthol-5-sulfonic acid while stirring, stir for 40min until complete dissolution and suction filtration, and the filtrate drops to 10-15°C for later use.

[0092] Add water into the dissolving pot, start stirring, add 117Kg of liquid caustic soda, adjust the temperature to 65-70°C, turn on the vacuum to inhale the melted N,N-diethyl-m-hydroxyaniline, keep stirring for one hour, and suction and filter the whole solution . The filtrate will be stored at 10°C for later use.

[0093] b. Once diazotization

[0094] Add 680L water, 235.62Kg 2-amino-5-nitrophenol into the L reactor, adjust pH=12.5-13 with liquid caustic soda, stir to dissolve completely, add 153Kg hydrochloric acid, cool down to 0-5°C, at this temperature, It takes 30 minutes to add 105.4Kg of nitrous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com