Chemical copper plating method for liquid-phase PEG (Polyethylene Glycol) optically-grafted modified PET (Polyethylene Glycol Terephthalate) film

A technology of electroless copper plating and photografting, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of strong irritation and corrosiveness of acrylic acid, unfavorable industrial operation, increase cost, etc. Excellent comprehensive performance, smooth and bright surface, and the effect of improving bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) PET film chemical degreasing and micro-etching: Put the PET film in 20g / L NaOH, 1g / L SDBS (sodium dodecylbenzenesulfonate), 3g / L NaOH 2 CO 3 , 5g / L Na 3 PO 4 12H 2 Soak in the mixed solution of O for 10 minutes at 50°C and rinse with tap water.

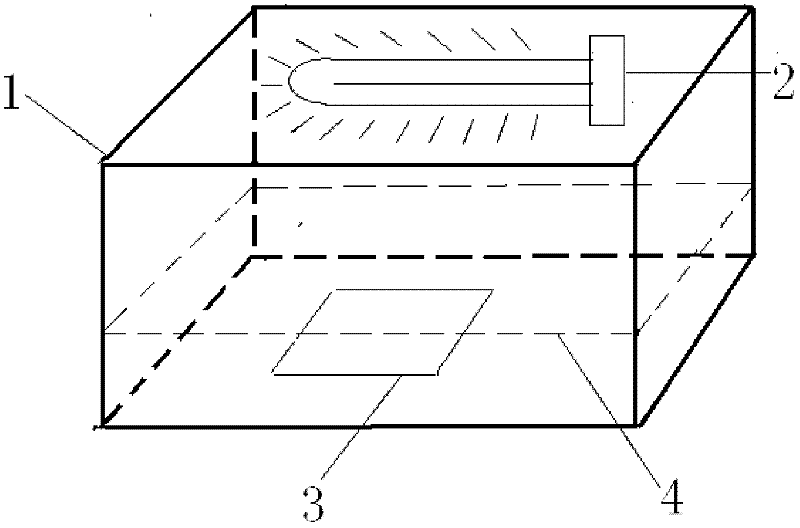

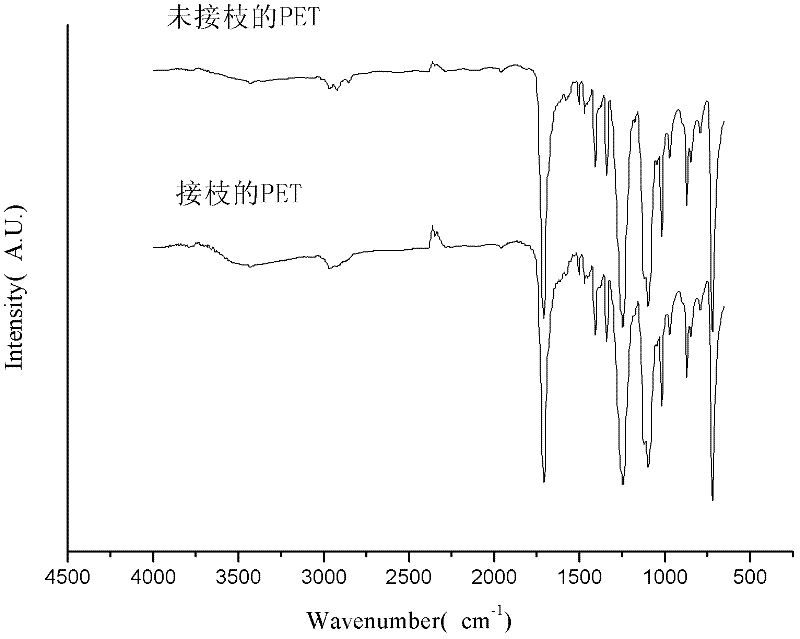

[0016] (2) Liquid-phase photografting: the PET film after degreasing is placed in the PEG (average molecular weight is 12000) and 1wt% potassium persulfate solution containing 0.02mol / L, the depth of solution is 1cm. The power of the ultraviolet lamp is 15W, the dominant wavelength is 200nm, and the height of the lamp from the liquid surface is 2cm. The photografting time was 20 minutes.

[0017] (3) Activation: Rinse the grafted PET membrane with deionized water, and then put it in a solution containing 0.5g / LAgNO 3 and 10mL / L 37%NH 3 ·H 2 O solution for 2 minutes, and finally rinse the surface of the PET film with deionized water.

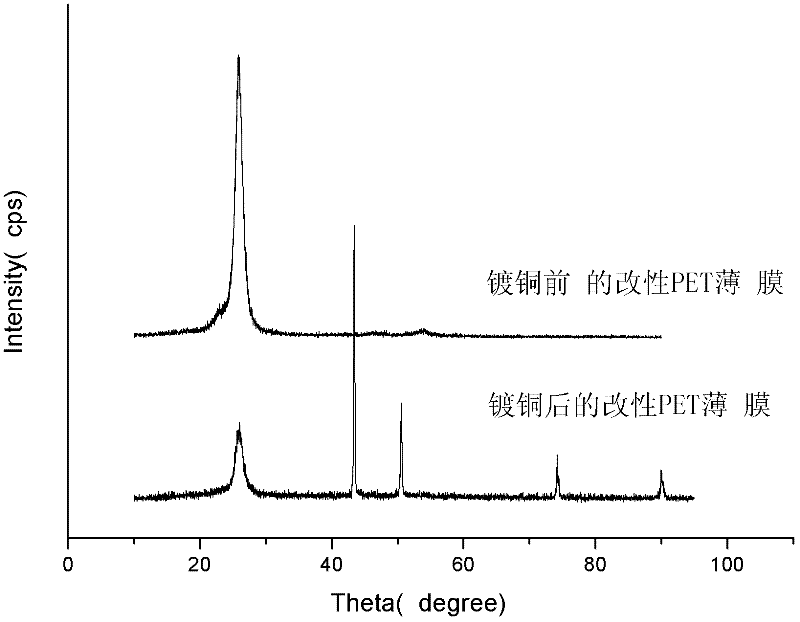

[0018] (4) Electroless copper plating: Put the activated PET film into the electr...

Embodiment 2

[0020] (1) PET film chemical degreasing and micro-etching: Put the PET film in 20g / L NaOH, 1g / L SDBS (sodium dodecylbenzenesulfonate), 3g / L NaOH 2 CO 3 , 5g / L Na 3 PO 4 12H 2 Soak in the mixed solution of O for 10 minutes at 50°C and rinse with tap water.

[0021] (2) Liquid-phase photografting: the PET film after degreasing is placed in the PEG (average molecular weight is 12000) and 1wt% potassium persulfate solution containing 0.025mol / L, the depth of solution is 1cm. The power of the ultraviolet lamp is 15W, the dominant wavelength is 200nm, and the height of the lamp from the liquid surface is 3cm. The photografting time was 15 minutes.

[0022] (3) Activation: Rinse the grafted PET membrane with deionized water, and then put it in a solution containing 0.5g / LAgNO 3 and 10mL / L 37%NH 3 ·H 2 O solution for 1 minute, and finally rinse the surface of the PET film with deionized water.

[0023] (4) Electroless copper plating: Put the activated PET film into the electr...

Embodiment 3

[0025] (1) PET film chemical degreasing and micro-etching: Put the PET film in 20g / L NaOH, 1g / L SDBS (sodium dodecylbenzenesulfonate), 3g / L NaOH 2 CO 3 , 5g / L Na 3 PO 4 12H 2 Soak in the mixture of O for 10 min at 50 °C and rinse with tap water.

[0026] (2) Liquid-phase photografting: the PET film after degreasing is placed in the PEG (average molecular weight is 12000) and 1wt% potassium persulfate solution containing 0.03mol / L, the depth of solution is 1cm. The power of the ultraviolet lamp is 15W, the dominant wavelength is 200nm, and the height of the lamp from the liquid surface is 2cm. The photografting time is about 15 minutes.

[0027] (3) Activation: Rinse the grafted PET membrane with deionized water, and then put it in a solution containing 0.5g / LAgNO 3and 10mL / L 37%NH 3 ·H 2 O solution for 2 minutes, and finally rinse the surface of the PET film with deionized water.

[0028] (4) Electroless copper plating: Put the activated PET film into the electroless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com