Metallized membrane capacitor assembly

A technology of capacitor components and metallized films, applied in the field of capacitors, can solve problems such as easy explosion, and achieve the effects of high electric strength, high working voltage, good mechanical properties and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

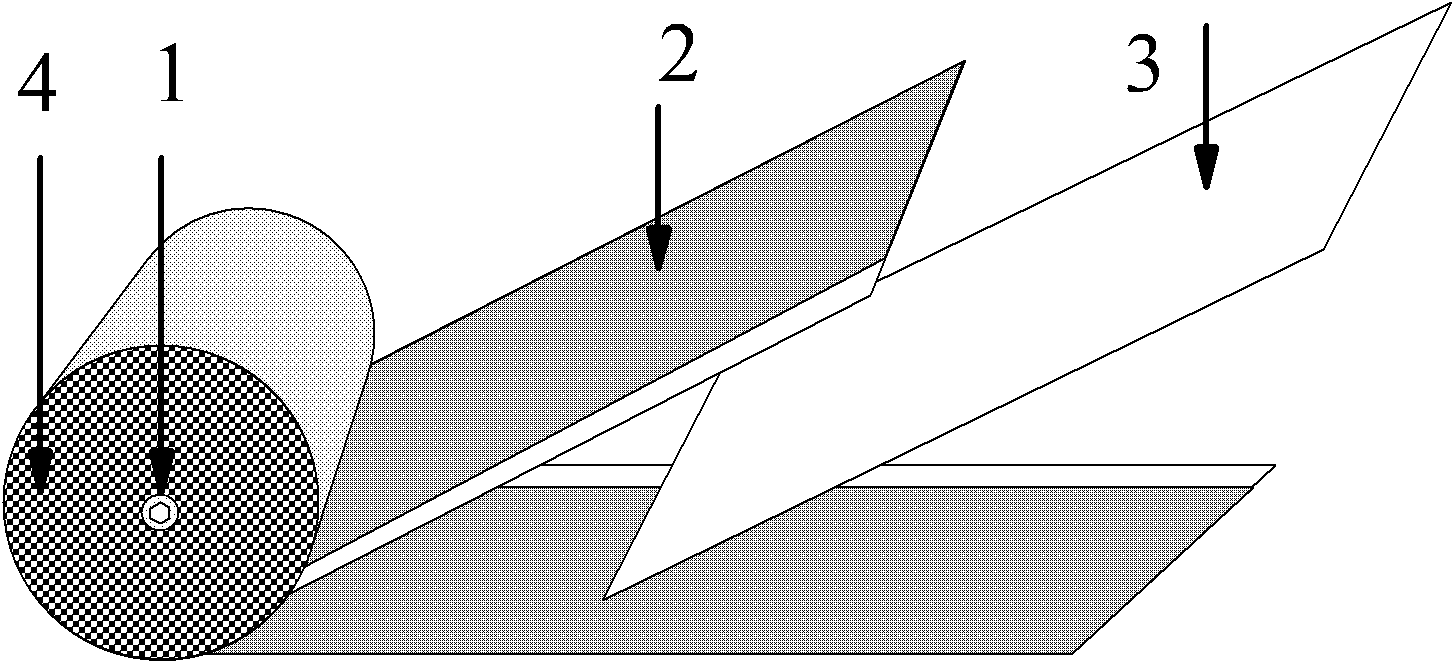

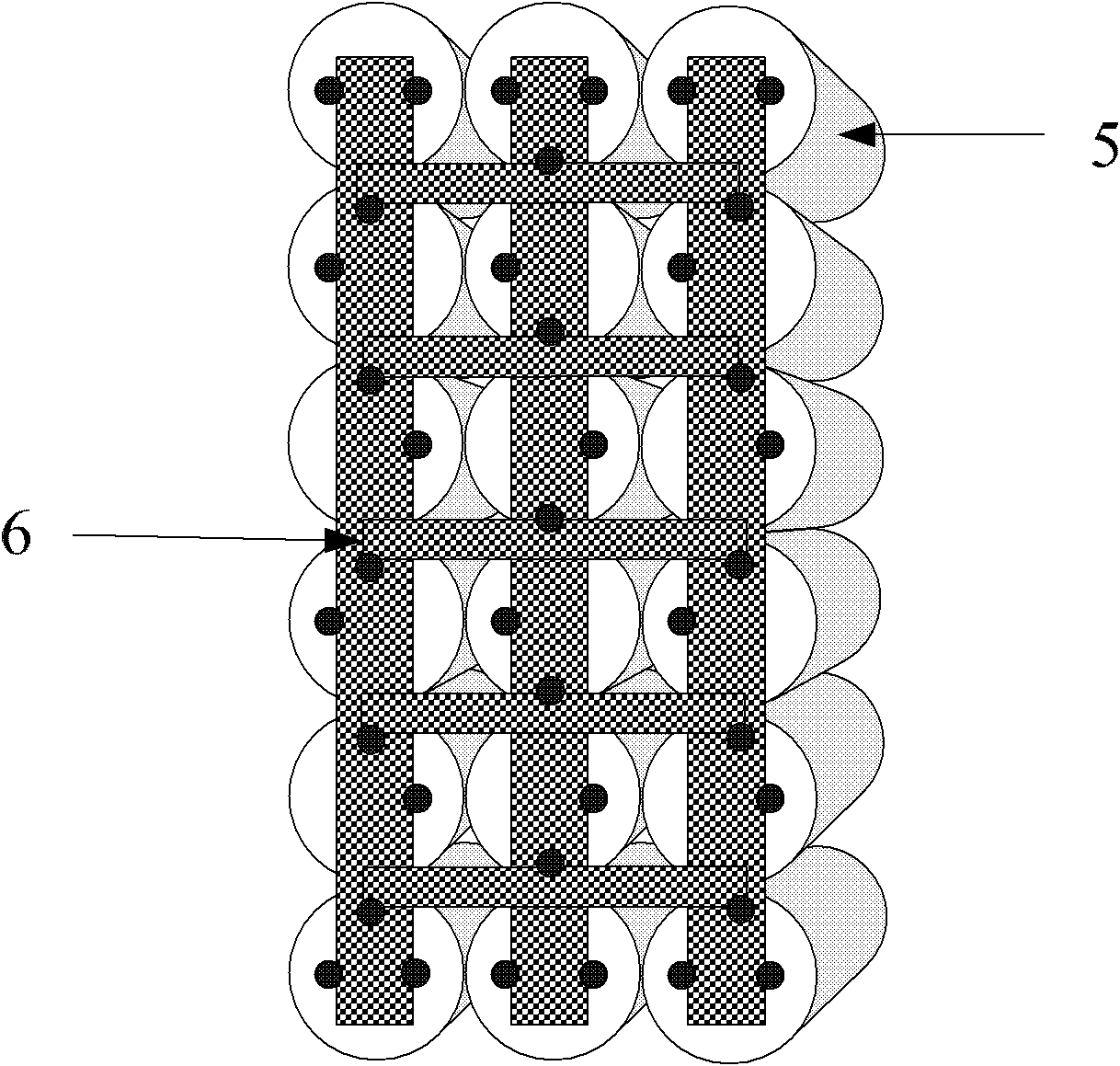

[0025] As shown in Figure 1(A), Figure 1(B), Figure 2(A), Figure 2(B), Figure 3(A), Figure 3(B), Figure 4(A), Figure 4(B) , The embodiment of the present invention includes capacitor core 5, copper bar 6, DMD insulating paper 8, bus bar 9, high voltage lead-out electrode 10a, low-voltage lead-out electrode 10b and polyurethane potting glue 11.

[0026] As shown in Figure 1(A) and Figure 1(B), the capacitor core 5 is wound together on the mandrel 1 by stacking two layers of metallized polypropylene film 2, and the two layers of metallized polypropylene film 2 are wound together. A polypropylene light film 3 is inserted between the ends, the polypropylene light film is wrapped outside the metallized polypropylene film 2, and then wound 20 times, and the metal layer 4 is sprayed on both ends after winding;

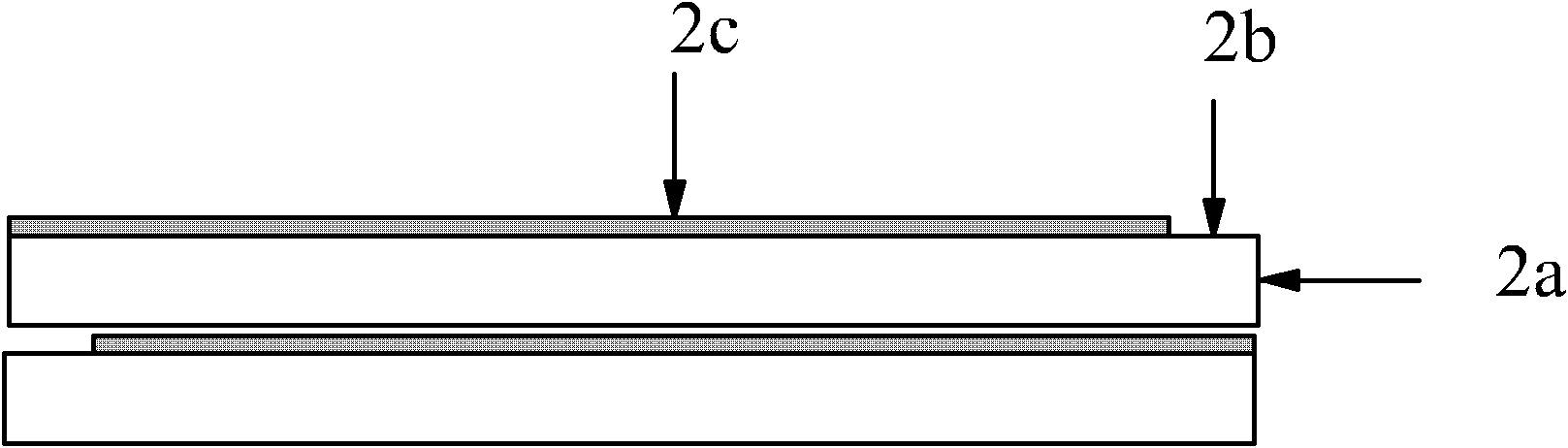

[0027] The structure of the metallized polyprop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com