Silicon-carbon composite material with high specific capacity, preparation method of silicon-carbon composite material, lithium ion battery anode material and lithium ion battery

A technology of silicon-carbon composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as slow attenuation, achieve simple preparation process, simple process steps, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

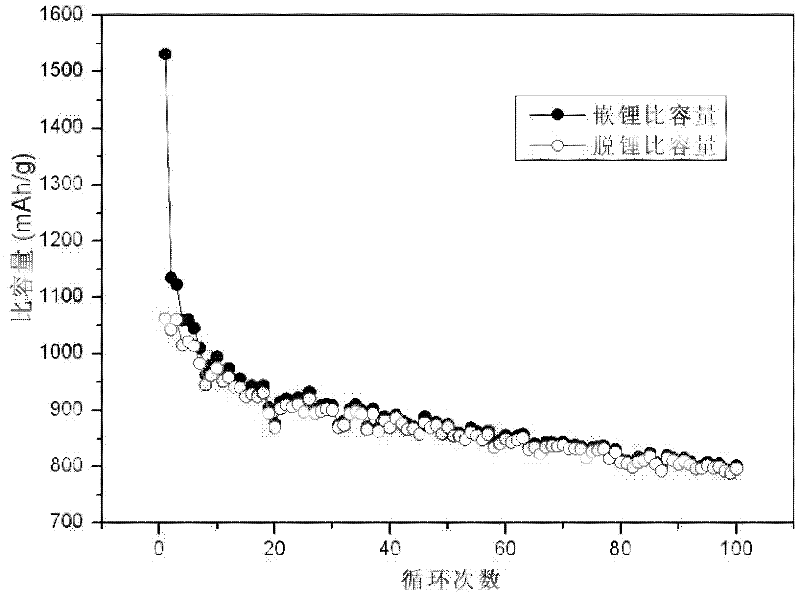

Embodiment 1

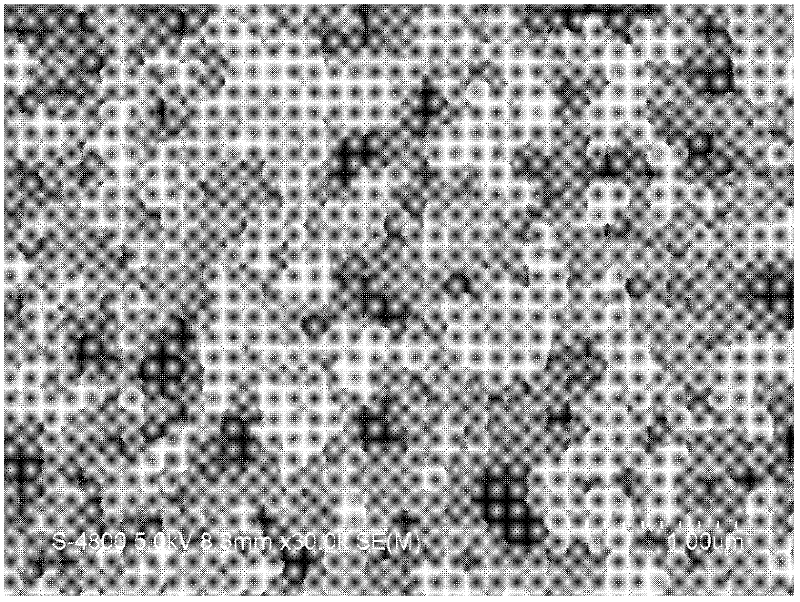

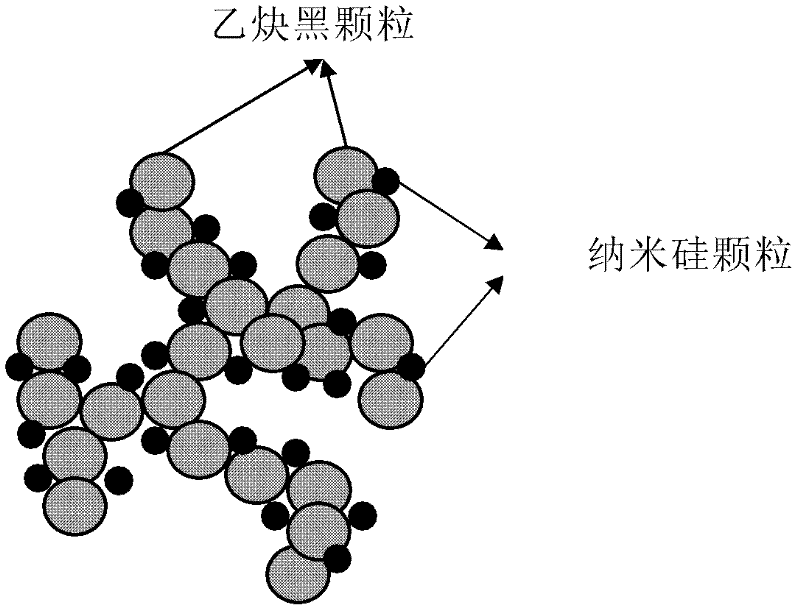

[0034] Weigh 8.8g of silicon monoxide and put it into a porcelain boat, raise the temperature to 800°C under the protection of nitrogen, keep the temperature at this temperature for 24 hours, make the disproportionation reaction of silicon monoxide at high temperature, and generate silicon dioxide-coated nano-silicon granular structure. After cooling to room temperature, 8.8 g of a tan product was obtained. The tan product includes incompletely reacted silicon monoxide, product silicon dioxide and nano-silicon, wherein the nano-silicon particles are uniformly dispersed in the silicon dioxide matrix.

[0035] Add the obtained tan product to 25ml of 40wt% hydrofluoric acid solution, add 3g of acetylene black at the same time, stir for 1 hour, and then ultrasonically disperse for 380 minutes. Hydrofluoric acid does not react, the silicon dioxide on the surface of nano-silicon particles reacts, and the incompletely reacted silicon monoxide in the previous high-temperature disprop...

Embodiment 2

[0041] Weigh 8.8g of silicon monoxide and put it into a porcelain boat, raise the temperature to 900°C under the protection of nitrogen, and keep the temperature at this temperature for 12 hours, so that the disproportionation reaction of silicon monoxide will occur at high temperature to form nano-silicon coated with silicon dioxide. granular structure. After cooling to room temperature, 8.8 g of a tan product was obtained. The tan product includes incompletely reacted silicon monoxide, product silicon dioxide and nano-silicon, wherein the nano-silicon particles are uniformly dispersed in the silicon dioxide matrix.

[0042] Add the obtained tan product to 200ml of hydrofluoric acid solution with a concentration of 20wt%, and add 1.5g of expanded graphite at the same time, stir for 2 hours, and then ultrasonically disperse for 180 minutes. It does not react with hydrofluoric acid, the silicon dioxide on the surface of nano-silicon particles reacts, and the incompletely react...

Embodiment 3

[0046] Weigh 8.8g of silicon monoxide and put it into a porcelain boat, raise the temperature to 1000°C under the protection of argon, keep the temperature at this temperature for 10h, make the disproportionation reaction of silicon monoxide at high temperature, and generate silicon dioxide-coated nano Silicon particle structure. After cooling to room temperature, 8.8 g of a tan product was obtained. The tan product includes incompletely reacted silicon monoxide, product silicon dioxide and nano-silicon, wherein the nano-silicon particles are uniformly dispersed in the silicon dioxide matrix.

[0047] Add the obtained tan product to 120ml of hydrofluoric acid solution with a concentration of 20wt%, and add 5g of vapor-phase grown carbon fiber at the same time, stir for 2 hours, and then ultrasonically disperse for 30 minutes. It does not react with hydrofluoric acid, the silicon dioxide on the surface of nano-silicon particles reacts, and the incompletely reacted silicon mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com