Chitosan-based anti-freezing antibacterial spraying agent for cutting surfaces of rubber trees and preparation method thereof

A technology of spray and rubber tree, which is applied in the field of chitosan-based rubber tree antifreeze and antibacterial spray for cut surface and its preparation, can solve problems such as difficulty in popularization and use, single function and troublesome use and construction, and improve bark healing Effects of regeneration rate, portability, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The components of the spray in parts by weight are as follows:

[0048] Active ingredient 20 parts;

[0049] 2 parts of additive methyl hydroxyethyl cellulose;

[0050] Propellant trichlorofluoromethane 78 parts.

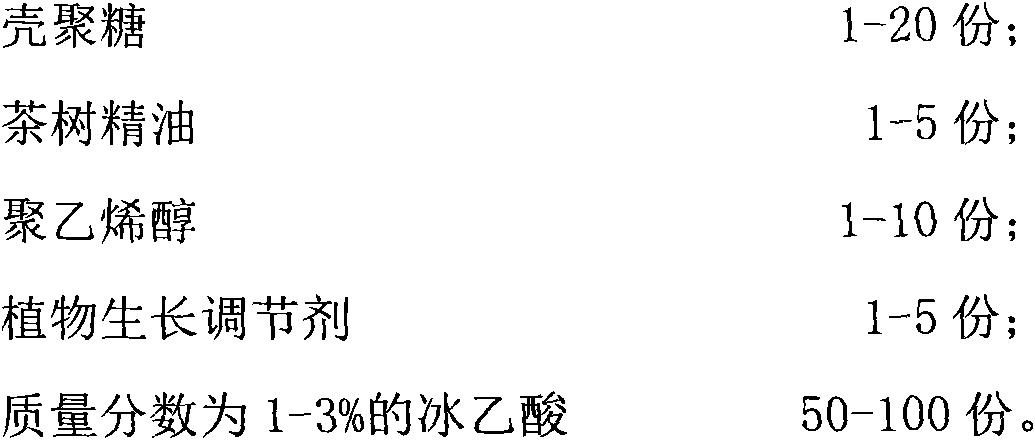

[0051] Wherein, the parts of chitosan, tea tree essential oil, polyvinyl alcohol, plant growth regulator and mass fraction of 1-3% glacial acetic acid in the active ingredient are:

[0052]

[0053] Weigh 2 parts of tea tree essential oil, 3 parts of polyvinyl alcohol, and 1 part of plant growth regulator indole acetic acid, grind and sieve 15 parts of chitosan and add them to 79 parts of glacial acetic acid with a mass fraction of 1-3%. Stir under constant pressure to dissolve, after complete dissolution, suction filter and discard insoluble matter, slowly add 2 parts of tea tree essential oil into the chitosan solution, then add 3 parts of polyvinyl alcohol, 1 part of plant growth regulator indole acetic acid, and obtain 20 parts of active ingredients...

Embodiment 2

[0055] The components of the spray in parts by weight are as follows:

[0056] 40 active ingredients;

[0057] Additive methyl hydroxyethyl cellulose 10 parts;

[0058] 50 parts of propellant difluoromethane.

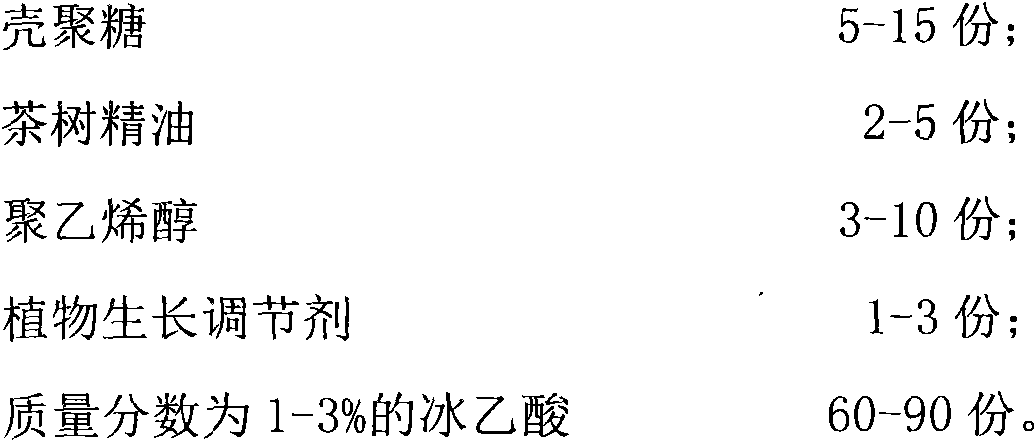

[0059] Wherein, the active ingredients of chitosan, tea tree essential oil, polyvinyl alcohol, plant growth regulator and glacial acetic acid with a mass fraction of 1-3% are as follows:

[0060]

[0061] 5 parts of tea tree essential oil, 10 parts of polyvinyl alcohol, 3 parts of plant growth regulator indole butyric acid were weighed, 5 parts of chitosan were ground and sieved, and then added to 77 parts of glacial acetic acid whose mass fraction was 1-3%, Stir and dissolve continuously at room temperature. After complete dissolution, suction filtration and discard insoluble substances. Slowly add 5 parts of tea tree essential oil into the chitosan solution, then add 10 parts of polyvinyl alcohol and 3 parts of plant growth regulator indole butyric acid. 40 parts ...

Embodiment 3

[0063] The components of the spray in parts by weight are as follows:

[0064] Active ingredients: 35 servings;

[0065] Additive 5 parts of sodium carboxymethyl cellulose;

[0066] 60 parts of propellant trichlorofluoromethane;

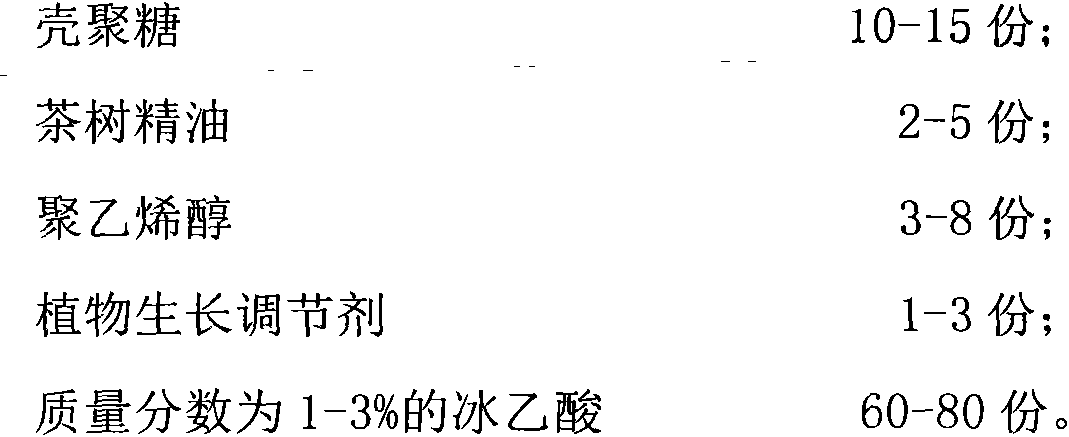

[0067] Wherein, the active ingredients of chitosan, tea tree essential oil, polyvinyl alcohol, plant growth regulator and glacial acetic acid with a mass fraction of 1-3% are as follows:

[0068]

[0069] 4 parts of tea tree essential oil, 4 parts of polyvinyl alcohol, 2 parts of plant growth regulator indole butyric acid were weighed, 10 parts of chitosan were ground and sieved, and then added to 80 parts of glacial acetic acid whose mass fraction was 1-3%, Stir and dissolve continuously at room temperature. After complete dissolution, suction filtration and discard insoluble substances. Slowly add 4 parts of tea tree essential oil into the chitosan solution, then add 4 parts of polyvinyl alcohol and 2 parts of plant growth regulator indole but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com