Extracting agent for treatment of wastewater in 2.4-D pesticide production

A production wastewater, 4-D technology, applied in natural water treatment, water/sewage treatment, extraction water/sewage treatment, etc., can solve the problem that the water phase and the extraction phase cannot be completely separated, the mass transfer driving force is reduced, and the solute is reduced Extraction rate and other issues, to restore the extraction effect, easy to separate, the effect of less carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

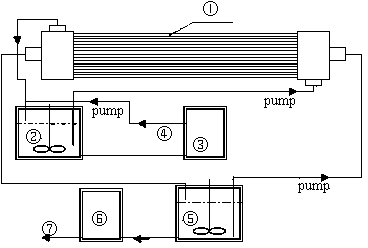

Method used

Image

Examples

Embodiment 1

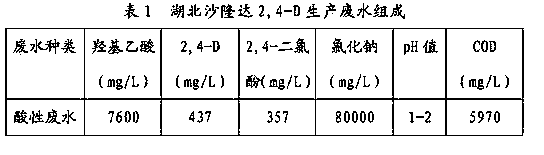

[0026] (1) The waste water used was taken from the acid waste water in Hubei Sanonda 2,4-D pesticide production waste water. The composition of the waste water is shown in Table 1.

[0027]

[0028] (2) Take the wastewater composed in Table 1, take 90 mL of complexing agent TOA (trioctylamine), 90 mL of co-solvent isooctyl alcohol, and 120 mL of diluent kerosene, mix them in a container containing 3000 mL, and turn on the stirrer (Stirrer speed is set to 2500r / min), stirring time is 30 min, after the extraction reaction is completed, pour it into the separator and let it stand for separation, and separate the oil and water two phases after the lower water phase is clarified. After testing, the concentrations of 2,4-D and 2,4-dichlorophenol in the raffinate aqueous phase separated after the extraction were 11.2 and 7.3 ppm, respectively. The concentrations of the two in the mother liquor wastewater are shown in Table 1. The calculated extraction rates reached 97.4% and 98.0%...

Embodiment 2

[0031](1) Take the wastewater in Table 1, take 100 mL of complexing agent trioctyl phosphate, 100 mL of co-solvent xylene, and 150 mL of diluent kerosene, mix them evenly and place them in a container containing 3500 mL, and turn on the stirrer (stirrer The rotation speed was set at 2500r / min), and the stirring time was 30 min. After the extraction reaction was completed, it was poured into a separator and left to stand for separation. After the lower aqueous phase was clarified, the oil and water phases were separated. After testing, the concentrations of 2,4-D and 2,4-dichlorophenol in the raffinate aqueous phase separated after the extraction are 45.1 and 112.4 ppm respectively, and the concentrations of the two in the mother liquor wastewater are the same as in Example 1, and the extraction rate is calculated They reached 89.7% and 68.5% respectively.

[0032] (2) Prepare 350mL of NaOH solution with a pH value of 11, mix it with the above separated oil phase and stir for 2...

Embodiment 3

[0034] (1) Take the wastewater in Table 1, take 100mL of complexing agent TOA (trioctylamine), 100mL of co-solvent n-octanol and 150mL of diluent xylene, put them in a container and mix them well, then take 2,4 -D Pesticide production wastewater 3500mL is placed in another container, then the prepared extractant is poured into the pesticide production water container and the two are stirred (the stirrer speed is set to 2500r / min) and mixed for 30min, and then poured into the separation Stand in the vessel for separation, and separate the oil and water phases after the lower water phase is clarified. The concentrations of 2,4-D and 2,4-dichlorophenol in the aqueous raffinate separated after 30 min of extraction were 9.8 and 6.3 ppm, respectively, and the extraction rates reached 97.8% and 98.2%, respectively.

[0035] (2) Prepare 350mL of NaOH solution with a pH value of 11, mix it with the above separated oil phase and stir for 20 min. After clarification, the oil phase and w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com