Treating method of arsenic in waste acid

A treatment method, technology of arsenic polluted acid, applied in the direction of water/sewage multi-stage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the final disposal or treatment of unfavorable waste residues, high treatment costs, and the amount of waste residues to reduce the risk of secondary pollution, reduce the output of waste residue, and reduce the amount of iron used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

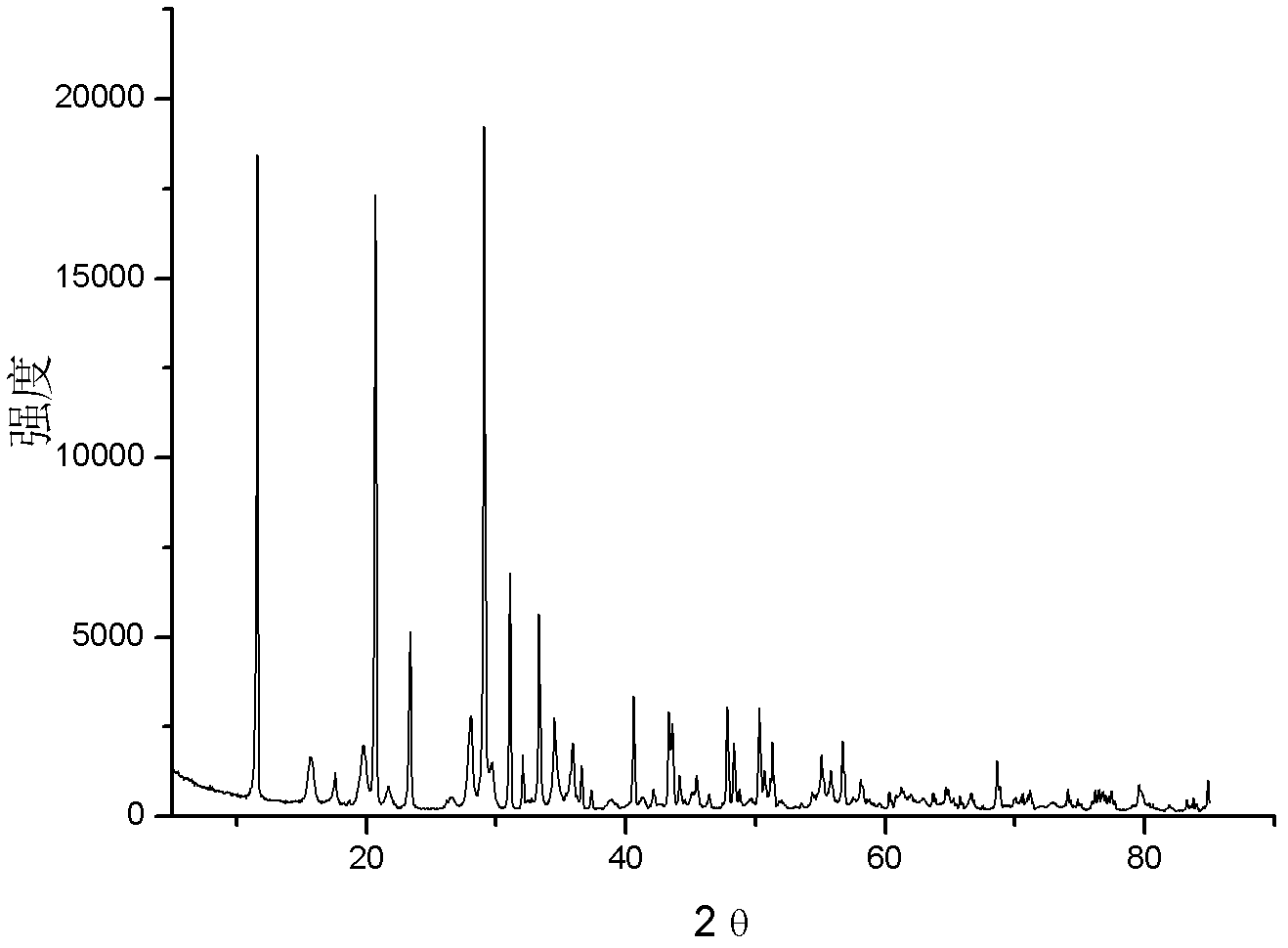

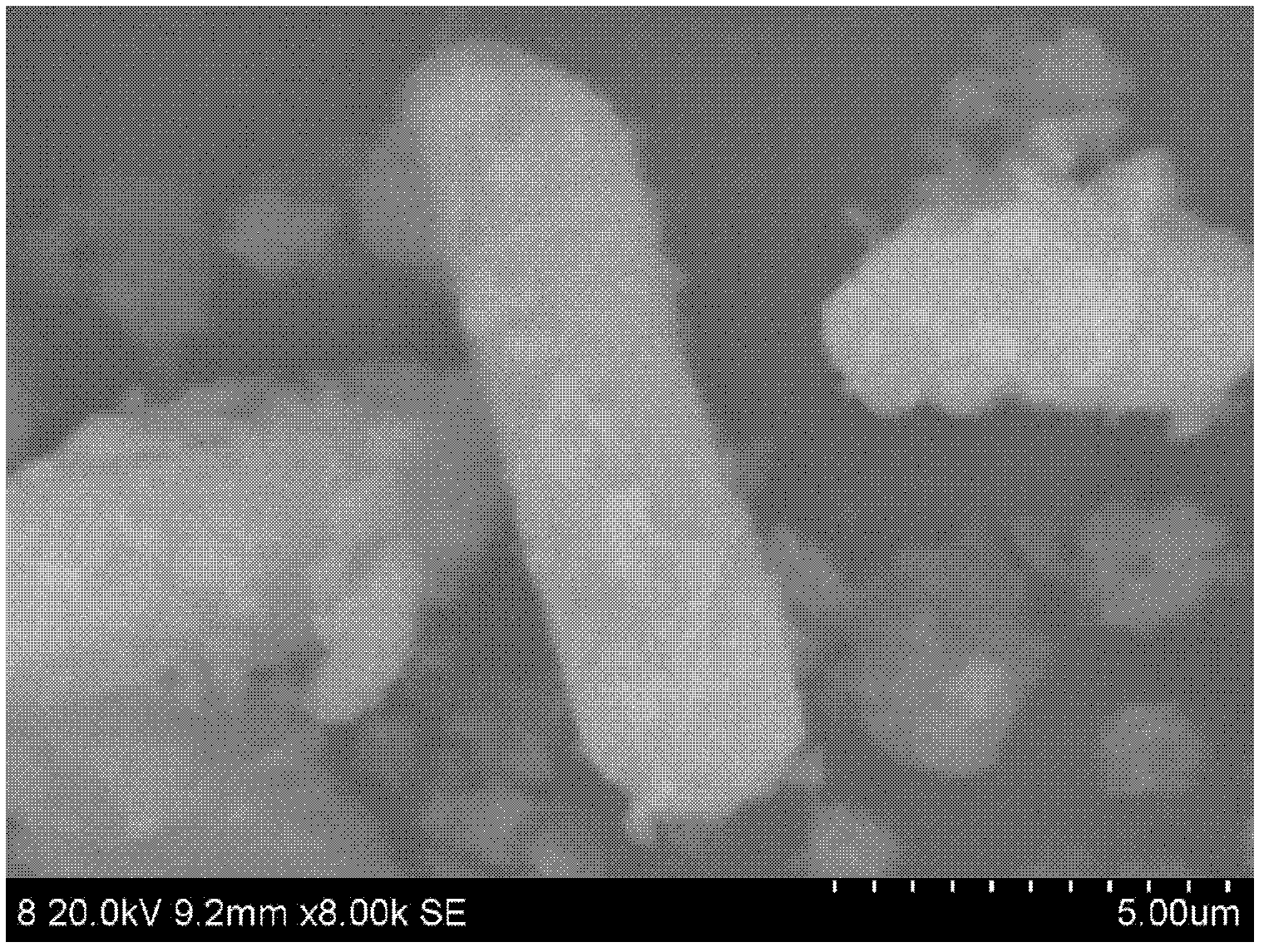

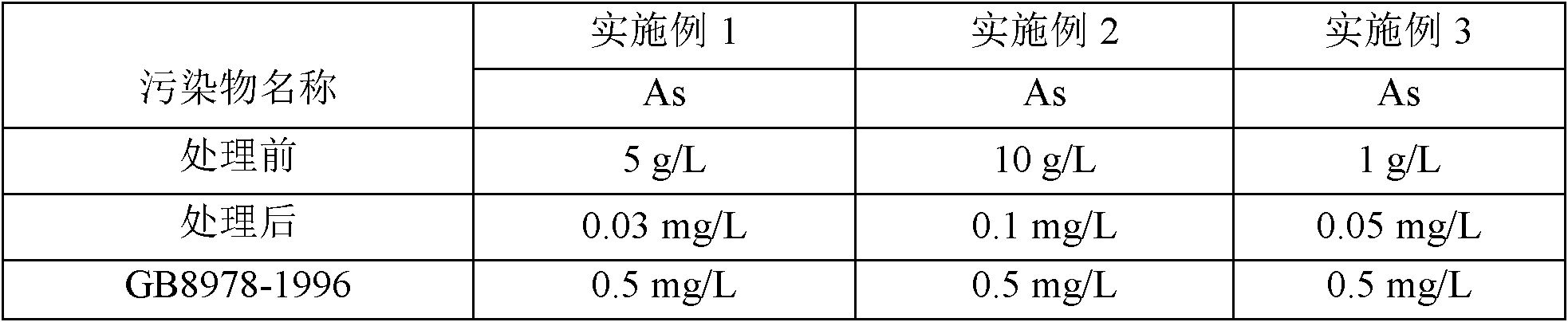

[0028] Sewage acid contains sulfuric acid 50g / L, As(III): 5g / L, calcium oxide is added at room temperature to neutralize to pH = 1, solid gypsum is obtained after solid-liquid separation, supernatant is added H 2 o 2 and ferric sulfate to make H 2 o 2 The molar ratio of Fe and As is 1.2, and the molar ratio of Fe and As is 0.8. After 30 minutes of oxidation reaction, continue to add calcium oxide to neutralize to pH=2. After solid-liquid separation, the supernatant should further remove arsenic, and add 1M H 2 SO 4 , dissolve part of the precipitate, make the pH of the mixture at 1.4, heat the mixture to 95°C, keep it under mechanical stirring (200rpm) for 5h, continue solid-liquid separation, and obtain a stable mixed precipitate of scorodite and calcium sulfate. The X-ray diffraction analysis and scanning electron microscope analysis pictures are as follows figure 1 and figure 2 As shown, the liquid after the two solid-liquid separations is added with iron sulfate at...

Embodiment 2

[0030] Sewage acid contains sulfuric acid 50g / L, As(III): 10g / L, add calcium oxide at room temperature to neutralize to pH=0.9, obtain solid gypsum after solid-liquid separation, add H to the supernatant 2 o 2 and ferric nitrate to make H 2 o 2 The molar ratio of Fe and As is 1.3, and the molar ratio of Fe and As is 1.0. After 30 minutes of oxidation reaction, continue to add calcium oxide to neutralize to pH=4. After solid-liquid separation, the supernatant should further remove arsenic, and add 2M H 2 SO 4 , dissolve part of the precipitate, make the pH of the mixture at 1.5, heat the mixture to 90°C, keep it under mechanical stirring (200rpm) for 6h, and continue the solid-liquid separation to obtain a stable mixed precipitate of scorodite and calcium sulfate. Add iron sulfate to the liquid after liquid separation according to the molar ratio of iron to arsenic being 2, continue to neutralize with calcium oxide suspension to pH=4, and separate solid and liquid.

Embodiment 3

[0032] Sewage acid contains sulfuric acid 80g / L, As(III): 8g / L, calcium oxide is added at room temperature to neutralize to pH = 1.2, solid gypsum is obtained after solid-liquid separation, supernatant is added H 2 o 2 and ferric chloride to make H 2 o 2 The molar ratio of Fe and As is 1.5, and the molar ratio of Fe and As is 1.2. After 30 minutes of oxidation reaction, continue to add calcium oxide to neutralize to pH=1.8. After solid-liquid separation, the supernatant should further remove arsenic, and add 1M H 2 SO 4 , dissolve part of the precipitate, so that the pH of the resulting mixture is 0.8, heat the solution to 80 ° C, keep it for 8 hours, and continue the solid-liquid separation to obtain a stable mixed precipitate of scorodite and calcium sulfate. The liquid after the two solid-liquid separations is press The molar ratio of iron to arsenic is 6, add ferric sulfate, continue to neutralize with calcium oxide suspension to pH=10, and separate solid and liquid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com