Method for alkaline leaching of waste residue containing zinc ferrite or lean zinc ore

A zinc ferrite leaching technology, which is applied in the field of alkaline leaching zinc ferrite waste residue or poor zinc ore, can solve the problems of limited applicability, difficulty in leaching by acid-base leaching, high cost, etc., and achieve good social and economic benefits. Benefit, no environmental pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

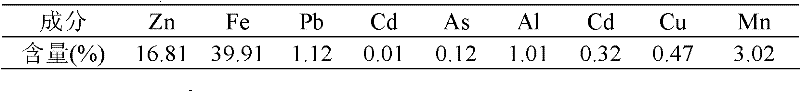

[0022] The dust from Changzhou Iron and Steel Plant in Jiangsu Province was used as the raw material, and its chemical composition is shown in Table 1. According to phase analysis, ZnFe 2 o 4 It accounts for 81% of the zinc content, and ZnO accounts for 19%.

[0023] Table 1 Chemical composition of soot from Changzhou Iron and Steel Plant in Jiangsu

[0024]

[0025] Add 100 g of the above-mentioned zinc ferrite-containing soot raw material into the stirred mill reactor, and simultaneously add 12-50 g of conversion agent (a mixture of commercially available industrial-grade sulfur and sodium sulfide mixed in any proportion), and the mass ratio of raw material: ball milling medium 1:25, the ball milling medium is corundum balls or stainless steel balls, under the stirring condition of 400-800 rpm, the mechanical activation conversion reaction is carried out for 2 hours, after the reaction is completed, the zinc ferrite in the raw material is converted into zinc sulfide; th...

Embodiment 2

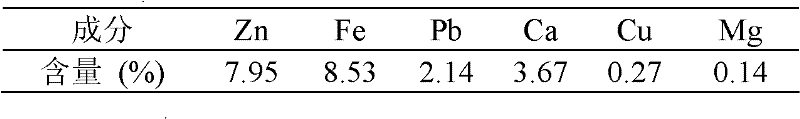

[0027] The zinc ferrite waste residue in Gejiu, Yunnan was used as the raw material, and its chemical composition is shown in Table 2. According to phase analysis, ZnFe 2 o 4 It accounts for 73% of the zinc content, ZnS accounts for 2.5%, ZnSO 4 Accounted for 24.5%.

[0028] Table 2 Chemical composition of Yunnan Mengzi zinc concentrate

[0029]

[0030] 100g of the above-mentioned zinc ferrite-containing waste slag is added to the stirred mill reactor, and 5-25g of conversion agent (the mixture of commercially available industrial grade sulfur and barium sulfide mixed in any proportion) is added at the same time, and the raw material: ball milling medium mass ratio is 1:20, the ball milling medium is corundum balls or stainless steel balls, under the stirring condition of 400-800 rpm, carry out the mechanical activation conversion reaction for 2 hours, after the reaction is completed, the zinc ferrite in the raw material is converted into zinc sulfide; then add alkali ...

Embodiment 3

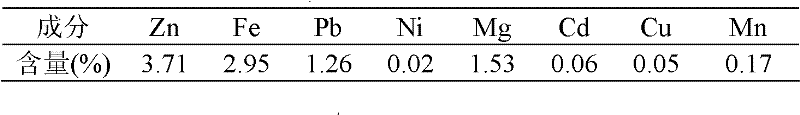

[0032] The raw material is Hezhang impurity zinc ore in Guizhou, and its chemical composition is shown in Table 3. According to phase analysis, ZnFe 2 o 4 Accounting for 47% of its zinc content, ZnO and Zn 2 SiO 4 53%.

[0033] Table 3 Chemical composition of Hezhang poor zinc ore (%)

[0034]

[0035] Add 100g of the above-mentioned zinc ferrite-containing poor zinc ore into the stirred mill reactor, and at the same time add 2-10g of conversion agent (a mixture of commercially available industrial grade sulfur and calcium sulfide mixed in any proportion), and raw materials: ball milling medium The mass ratio is 1:15, and the ball milling medium is corundum balls or stainless steel balls. Under the stirring condition of 400-800 rpm, the mechanical activation conversion reaction is carried out for 2 hours. After the reaction is completed, the zinc ferrite in the raw material is converted into zinc sulfide; Then add 500ml of alkaline solution with an alkali concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com