Ce-based amorphous alloy and preparation method thereof

An amorphous alloy, cerium-based technology, applied in the field of cerium-based amorphous alloy and its preparation, amorphous alloy and its preparation, can solve the problems of limited application range, unfavorable engineering application, and inability to do it, and achieve the goal of overcoming mold heat Effects of damage, difficulty reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

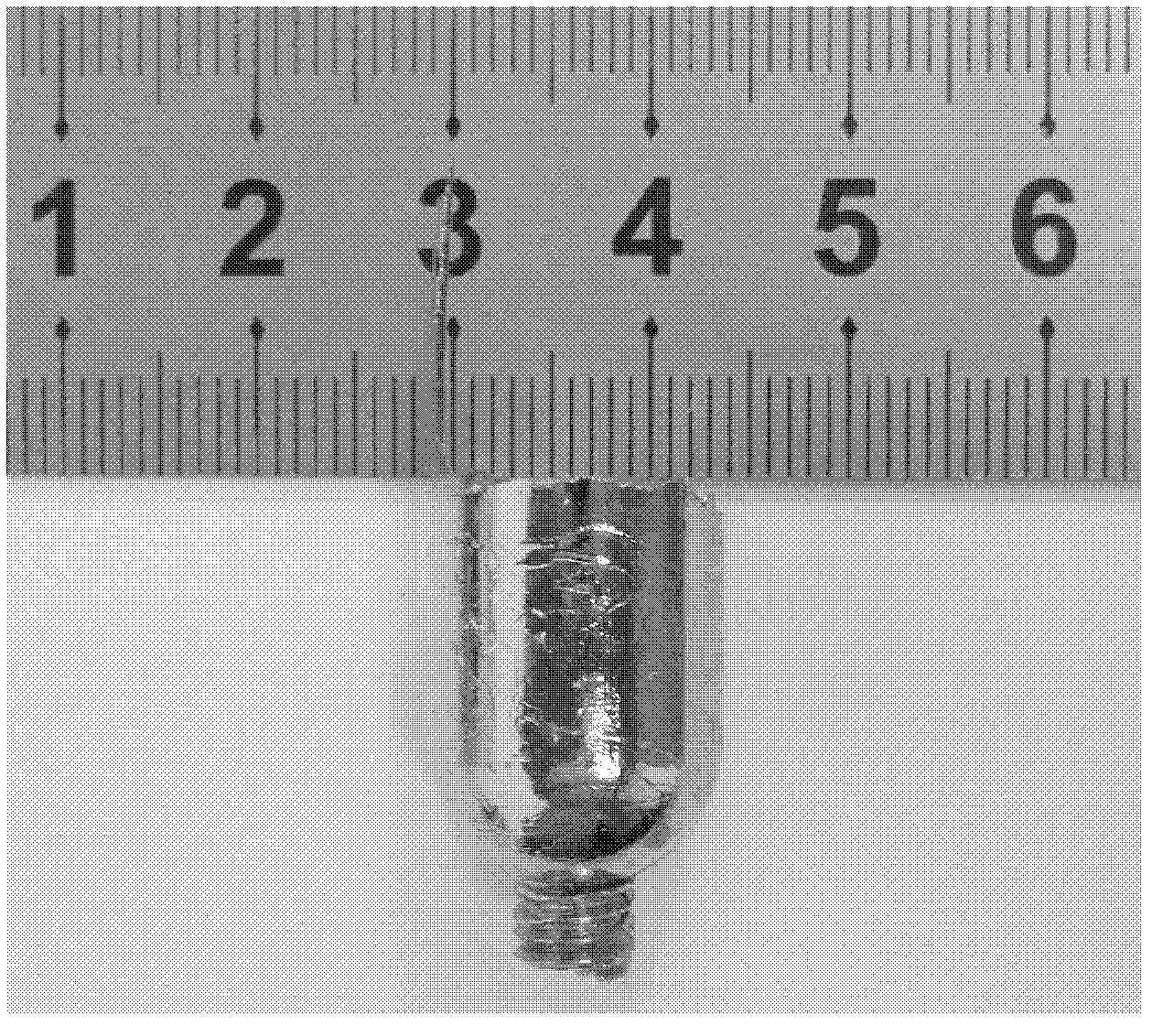

[0032] Example 1, Ce 70 Ga 8.5 Cu 21.5 bulk amorphous alloy

[0033] Using Ce with a purity of 99.5% and Ga and Cu with a purity above 99.9%, according to the chemical formula Ce 70 Ga 8.5 Cu 21.5 The atomic percentage of the alloy is formulated, and the alloy is melted in a vacuum arc melting suction casting furnace with argon gas adsorbed by titanium. The number of melting times is not less than 4 times, so that the composition of the alloy is uniform. After cooling, a master alloy ingot is obtained. Then use the suction casting device in the electric arc furnace to suction cast the remelted master alloy melt into a cylindrical copper mold to obtain a cerium-based amorphous alloy material, heat it above its glass transition temperature, and shape it into a diameter of 14mm Ce 70 Ga 8.5 Cu 21.5 Amorphous alloy rod.

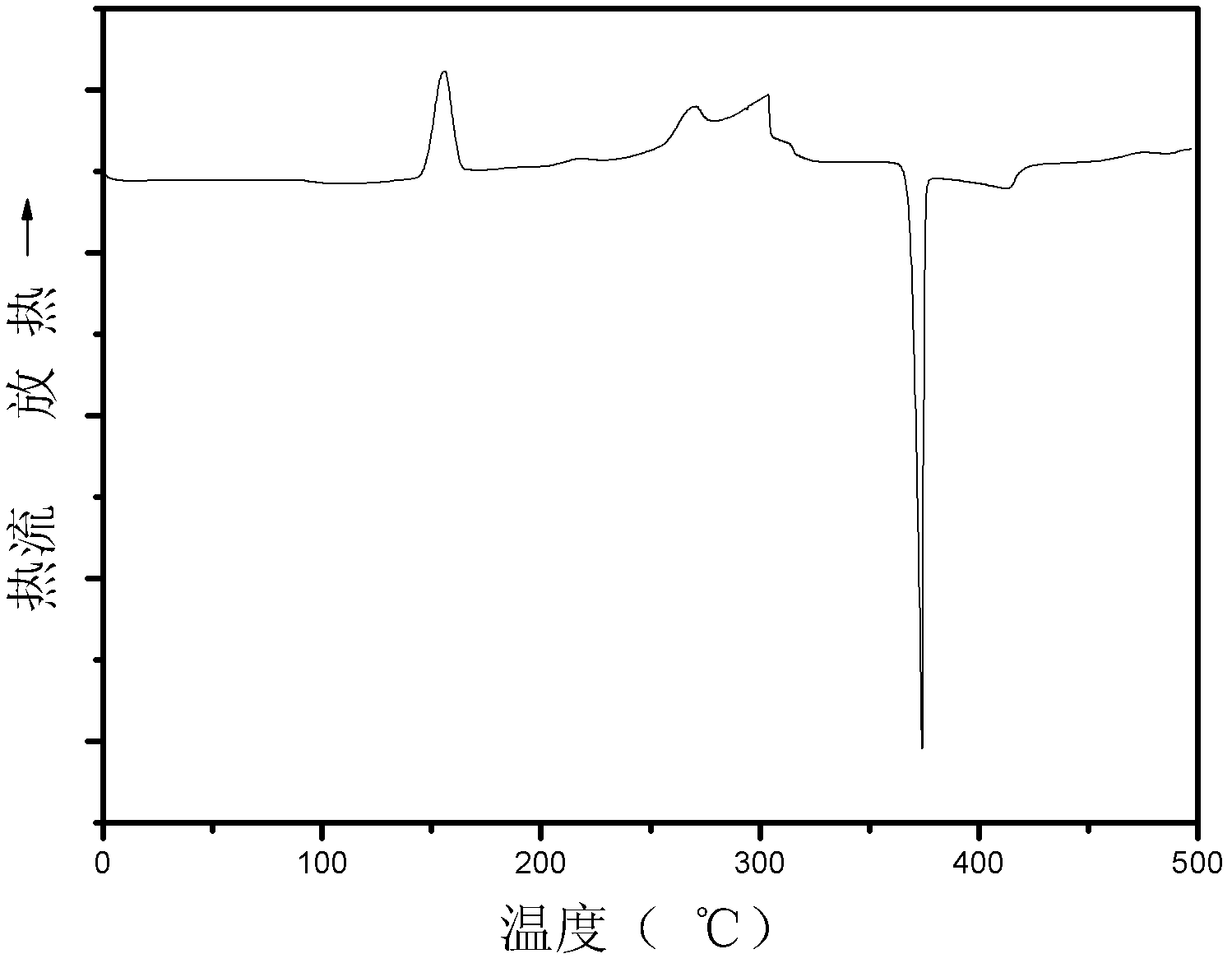

[0034] Ce with a diameter of 14mm 70 Ga 8.5 Cu 21.5 Alloy rods are almost completely amorphous in the as-cast state. Depend on figure 1 It can be...

Embodiment 2-9

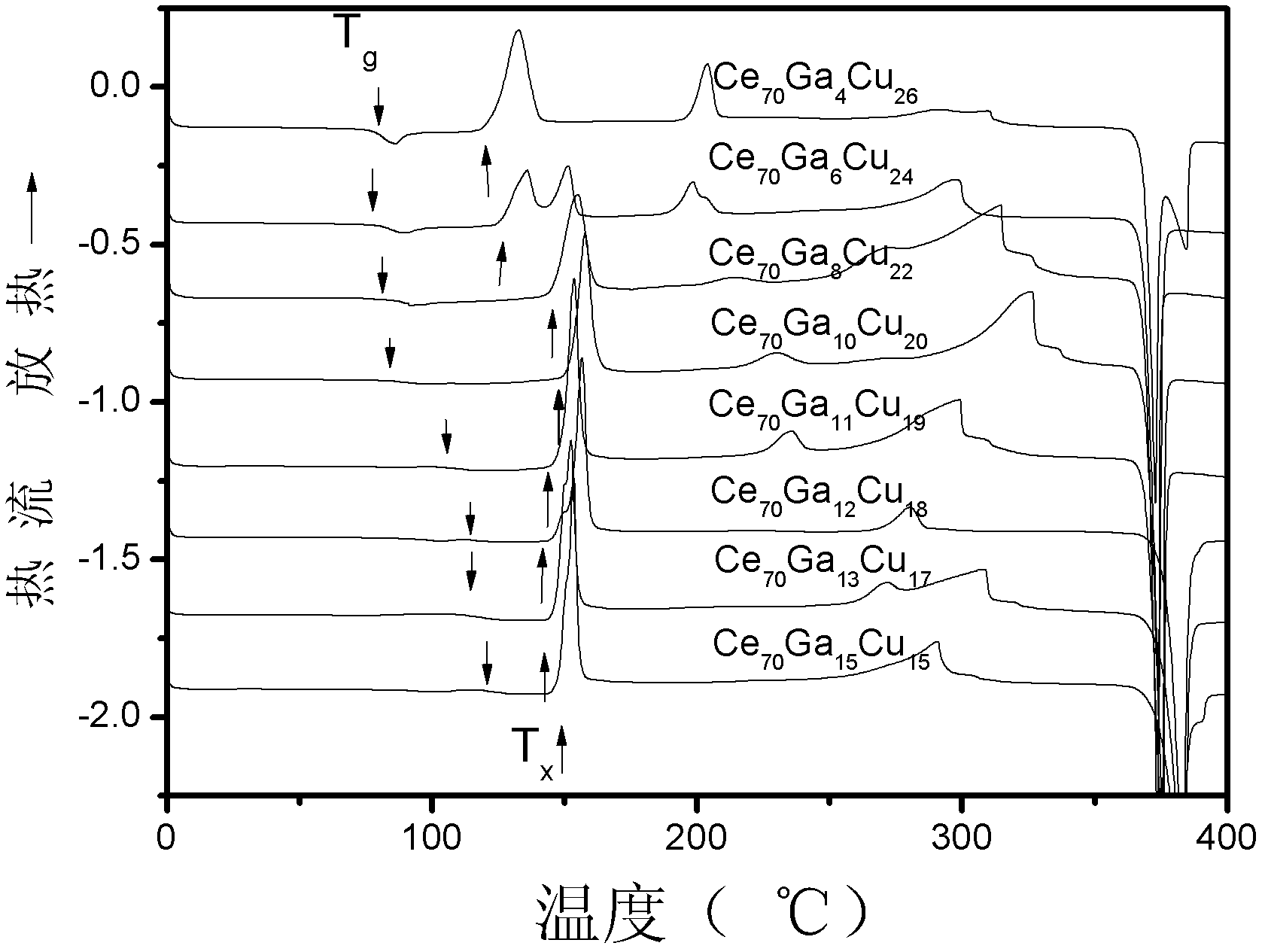

[0036] Embodiment 2-9, Ce-Ga-Cu bulk amorphous alloy

[0037] According to the method of Example 1, Examples 2-9 can also obtain bulk amorphous with a critical dimension of at least 2 mm. Its DSC curve and XRD image are listed in image 3 and Figure 7 . Depend on image 3 and Figure 7 It can be seen that the alloy system can easily obtain a bulk amorphous alloy, and the Tg points of the alloy are all around 100°C, which is conducive to processing the alloy in the supercooled liquid phase region. The width of the supercooled liquid phase region of the alloy system is above 29K, which provides a larger temperature selection range for deformation in the supercooled liquid phase region. Lower than the boiling point of water and a larger temperature range can make the amorphous alloy of this alloy series undergo thermoplastic deformation like engineering plastics. Depend on Figure 8 It can be seen that Ce 70 Ga 10 Cu 20 Alloy at glass transition temperature T g Deforma...

Embodiment 10-19

[0043] Embodiment 10-19, Ce-Ga-Cu-Co(Ni) bulk amorphous alloy

[0044] According to the method of Example 1, Examples 10-19 can obtain bulk amorphous with a critical dimension of at least 10 mm. Its characteristic data are shown in Table 2. Figure 4 , Figure 5 . The width of the maximum supercooled liquid phase region Tx of this alloy system is close to 70K at most, and the glass forming ability is generally better than the alloys of Example 1 and Examples 2-9. Although the Tg point of the alloy has increased, it is still below 120°C, which is much lower than the Tg point of other metallic glasses.

[0045] Table 2 Thermophysical parameters of some alloys in Ce-Ga-Cu-Co(Ni) alloy system

[0046] Example

[0047] Note: The DSC experimental heating rate of the samples of each component in the table is 20K / min, and the DSC equipment model: PE8000

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com