Magnesium alloy surface anticorrosive treatment method and magnesium product thereof

An anti-corrosion treatment, magnesium alloy technology, applied in the direction of thin material treatment, metal material coating process, ion implantation plating, etc., can solve the problems of easy pitting corrosion, poor protection ability, large environmental pollution, etc., and achieve good corrosion resistance. Performance, good anticorrosion function, high chemical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

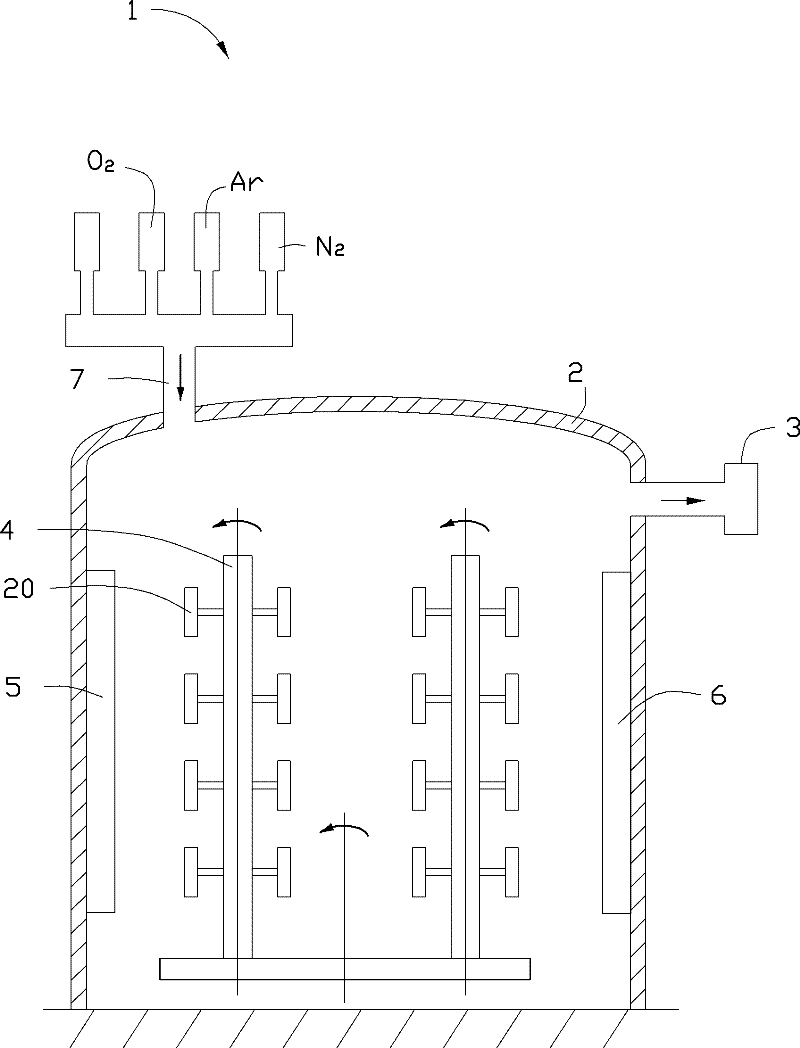

[0030] The preferred embodiment of the present invention magnesium alloy surface anti-corrosion treatment method comprises the following steps:

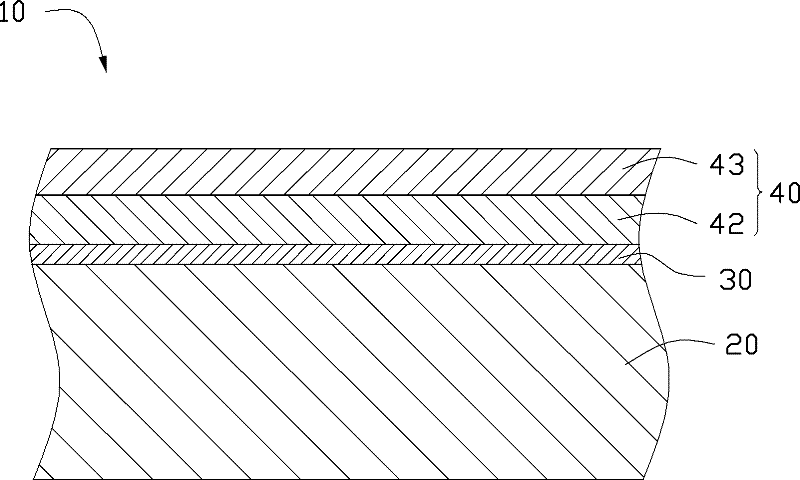

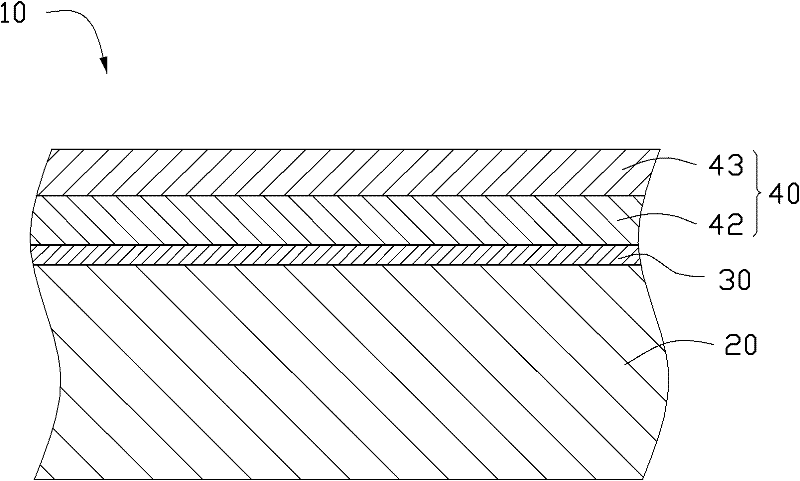

[0031] see figure 1 , providing a magnesium alloy substrate 20 .

[0032] The magnesium alloy substrate 20 is chemically degreased. Chemical degreasing involves immersing the magnesium alloy substrate 20 in a degreasing solution at 60-80°C for 30-60s. The degreasing solution used is containing 25-30g / L sodium carbonate (Na 2 CO 3 ), 20-25g / L trisodium phosphate (Na 3 PO 4 12H 2 O) and the aqueous solution of 1-3g / L emulsifier, wherein said emulsifier can be OP-10 emulsifier, and its main component is the condensation product of alkylphenol and oxirane.

[0033] Alkaline etching treatment is performed on the magnesium alloy substrate 20 . The alkaline etching treatment step is to immerse the magnesium alloy substrate 20 in an alkaline etching solution at 40-50°C for 3-5s. The alkaline etching solution used is containing 40-70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com