Magnetic particle chemical luminous kit for detecting clenbuterol and application thereof

A chemiluminescence detection and kit technology, which is applied in chemiluminescence/bioluminescence, analysis by making materials react chemically, and measurement devices, can solve the problems of low false positive rate, expensive detection cost, cumbersome operation, etc., and achieve High sensitivity, fast detection, and low detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of specific components of the kit

[0037] 1. Preparation of Luminescent Labels

[0038] a) Synthesis of Clenbuterol Hapten

[0039] Clenbuterol is acylated with succinic anhydride to acylate the alcohol hydroxyl group on the molecular structure of clenbuterol into a clenbuterol hapten containing a 4-carbon carboxyl indirect arm.

[0040] b) Preparation of Luminescent Labels

[0041] Take 4.5mmol / L ABEI, dissolve it in 4ml distilled water, dissolve 5.0mmol / L N-hydroxysuccinimide in 0.5ml N,N-dimethylformamide, mix the two thoroughly and react at room temperature for 3-4h . Take 15 mg of the clenbuterol hapten prepared above, adjust the volume to 1.5 ml with pH 7.4 PBS, then add the above activated ABEI solution, mix well, react overnight at room temperature, and purify through G-25 gel column.

[0042] 2. Preparation of fluorescent markers

[0043] a) Preparation of immunogens:

[0044] The immunogen was obtained by coupling the clenbuterol h...

Embodiment 2

[0057] The formation of the second test kit

[0058] A magnetic particle chemiluminescence detection kit for clenbuterol was constructed to contain the following components:

[0059] Fluorescent label for FITC-labeled clenbuterol monoclonal antibody

[0060] Luminescent marker of ABEI-labeled clenbuterol hapten

[0061] Separation Reagent for Paramagnetic Nanospheres Coated with Goat Anti-FITC Monoclonal Antibody

[0062] Clenbuterol standard solution (0ng / ml, 0.01ng / ml, 0.03ng / ml, 0.09ng / ml, 0.27ng / ml, 0.81ng / ml), the standard dilution is pH7.4, containing 0.03% NaN 3 , 0.05mol / L TRIS buffer. The percentage content is the mass percentage content.

[0063] The concentration of Clenbuterol quality control solution is 0.02ng / ml and 0.5ng / ml, respectively, and the quality control solution is pH7.4, containing 0.03% NaN 3 , 0.05mol / L TRIS buffer. The percentage content is the mass percentage content.

[0064] Concentrated wash solution pH 7.6, 0.4% Tween-20, 0.02% NaN 3 ,...

Embodiment 3

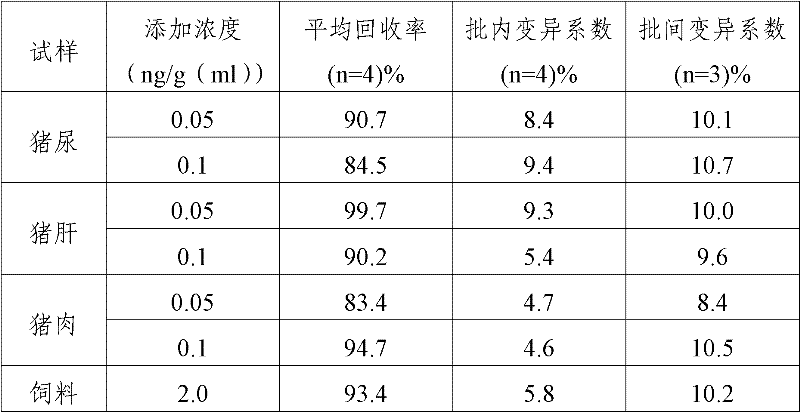

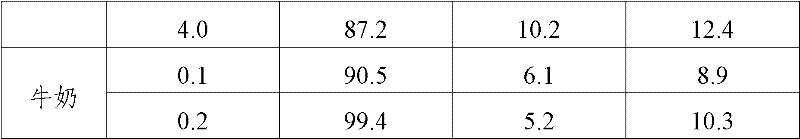

[0065] Example 3 Detection of Clenbuterol in Actual Samples

[0066] 1. Sample pretreatment

[0067] (1) Urine

[0068] Take 20μl of clear urine sample for direct determination (if the urine sample is cloudy, it must be filtered or more than 3000g, centrifuged at 15°C for 10min until clear), the sample not used temporarily should be frozen and stored, the sample dilution ratio: 1

[0069] (2) Tissues with low-fat meat, liver and other tissues

[0070] Weigh 2.0±0.05g of homogenized sample into a 50ml polystyrene centrifuge tube; add 6ml of 4% NaCl-0.1M HCl-methanol mixture, shake with a shaker until uniform; let stand for 10 minutes, centrifuge above 3000g for 5 minutes ; Liver samples: Take 1ml of supernatant and add 20μl of 1M sodium hydroxide solution and mix well (after mixing, measure the pH value, it is about 8); Muscle samples: Take 1ml of supernatant and add 30μl of 1M sodium hydroxide solution and mix well (mixed After homogenization, measure the pH value, about 8)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com