Semiconductor solar battery based on interface polaron effect and method for preparing semiconductor solar battery

A solar cell and interface polarization technology, applied in semiconductor devices, circuits, electrical components, etc., can solve the problems of low conversion efficiency of amorphous silicon thin film solar cells, problems of material sources, and high cost of raw materials, and achieve no environmental pollution. , The effect of low raw material cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

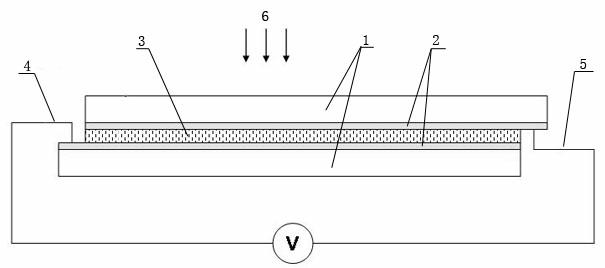

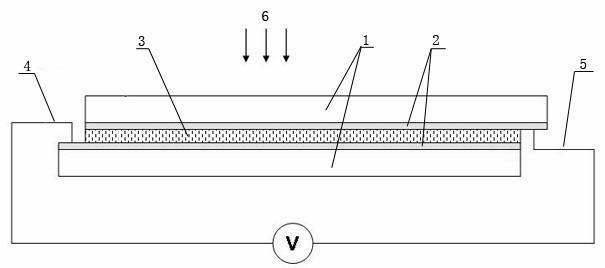

[0017] figure 1 Shown is the structural schematic diagram of the semiconductor solar cell based on the interface polaron effect made by the present invention. The cell consists of two pieces of conductive glass 1 of the same size and a layer of polaron oxide film 3 to form a centrosymmetric structure. Polar oxide film 3 is sandwiched between two pieces of conductive glass 1 and separates the two pieces of conductive glass 1. The side adjacent to conductive glass 1 and polaroid oxide film 3 has conductive film 2, and the two pieces of conductive glass 1 Staggered settings, one end edge of the conductive glass 1 is aligned with the edge of the polaron oxide film 3, and the other end protrudes from the polaron oxide film 3, and the two pieces of conductive glass 1 protrude from the conductive film of the polaron oxide film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com