Preparation method for saturable absorption mirror based on large-sized graphene

A graphene and absorption mirror technology, which is applied in the field of preparation of saturable absorption mirrors, can solve the problems of affecting the mode-locking effect of saturable absorption mirrors, poor graphene uniformity, and high cost, and achieves a simple and easy preparation process and a uniform graphene layer. , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

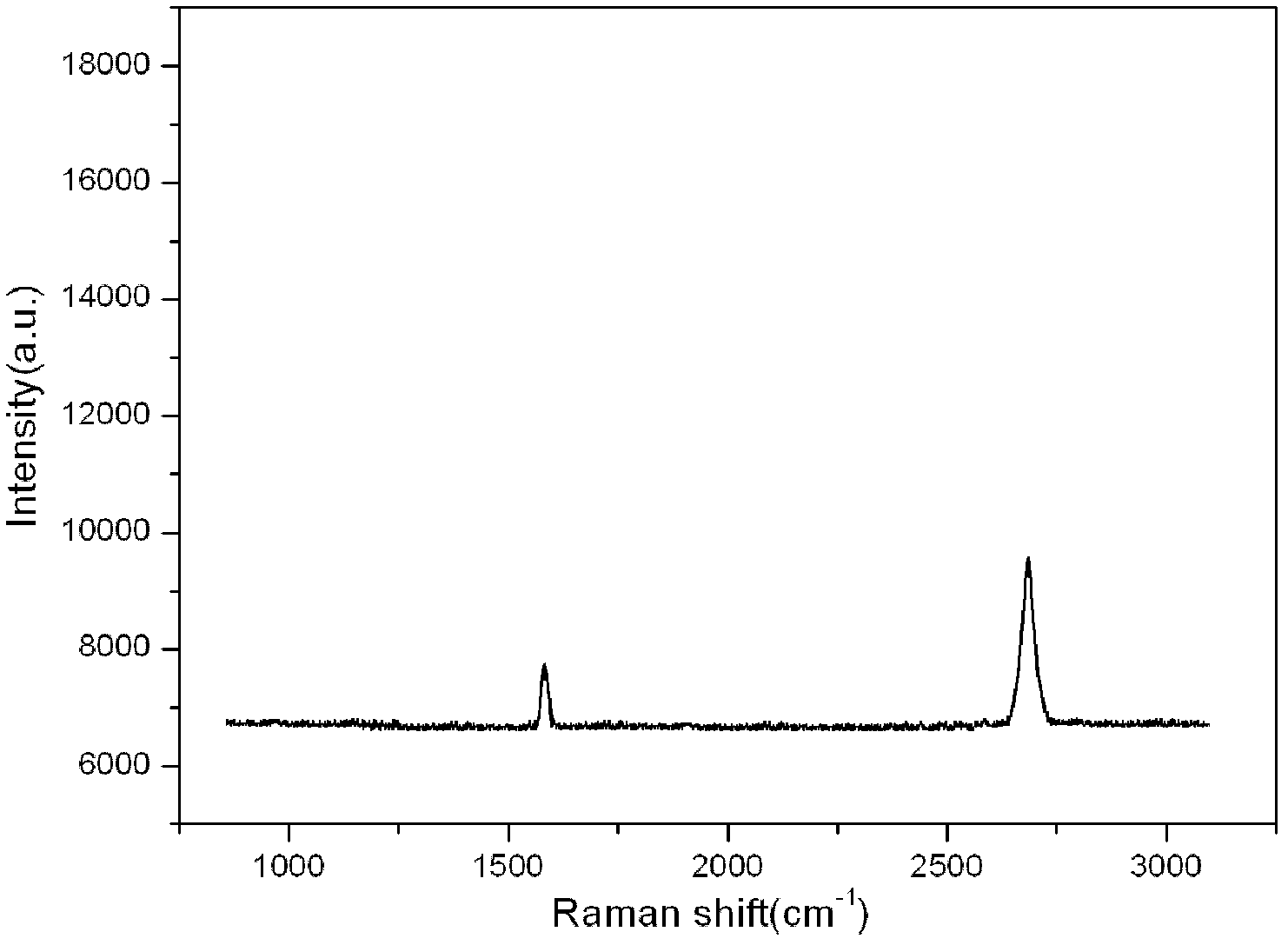

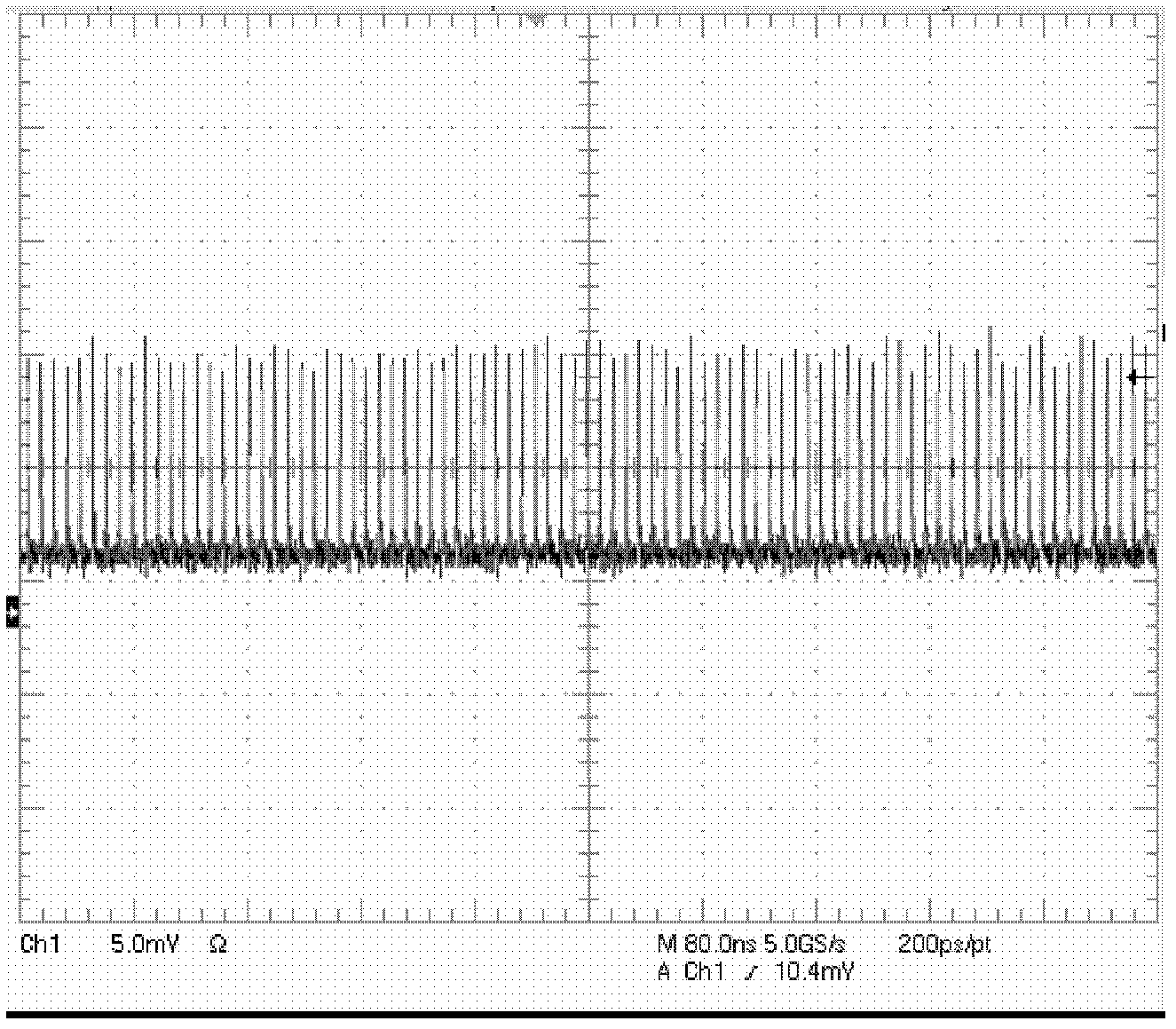

[0028] A preparation method of a graphene-based saturable absorbing mirror, comprising the following steps:

[0029] (1) Adopt CVD method to prepare single-layer graphene on Cu foil; Single-layer graphene adopts chemical vapor deposition to grow, and concrete steps are: at first the temperature of quartz tube is raised to 800-1100 degrees centigrade, then pass into 10-200sccm Hydrogen annealing for 5-30 minutes, and then one or two gases in methane and acetylene. The gas flow rate is 10-300 sccm, and after 5-60 minutes of growth, the carbon source gas is turned off and the temperature is rapidly cooled under a hydrogen atmosphere.

[0030] (2) Cut the Cu foil into φ20mm and φ25.4mm circles; cut the Cu foil according to the diameter of the laser high-reflection mirror, spin-coat PMMA on the circular Cu foil, and place the Cu foil on a 170°C hot plate after coating Bake for 5 minutes; Spin coating parameters of glue equalizing machine: first glue equalizing for 3s, rotating spe...

Embodiment 2

[0037] The specific steps are the same as in Example 1, the difference being that the process of steps (2)-(5) is repeated once, on the basis of transferring 1 layer of graphene saturable absorbing mirror, transfer 1 layer of graphene again, so that the saturable absorbing mirror above The number of layers of graphene is 2 layers.

Embodiment 3

[0039] The specific steps are the same as in Example 1, the difference is that after the steps of Example 1 are completed, repeat the steps (2)-(5) process twice, and transfer 1 layer of graphene on the basis of transferring 2 layers of graphene saturable absorbing mirrors , so that the number of layers of graphene on the saturable absorption mirror is 3 layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com