Colored conductive fluids for electrowetting and electrofluidic technologies

A conductive fluid, colored technology, used in organic dyes, instruments, optics, etc., can solve problems such as dielectric breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

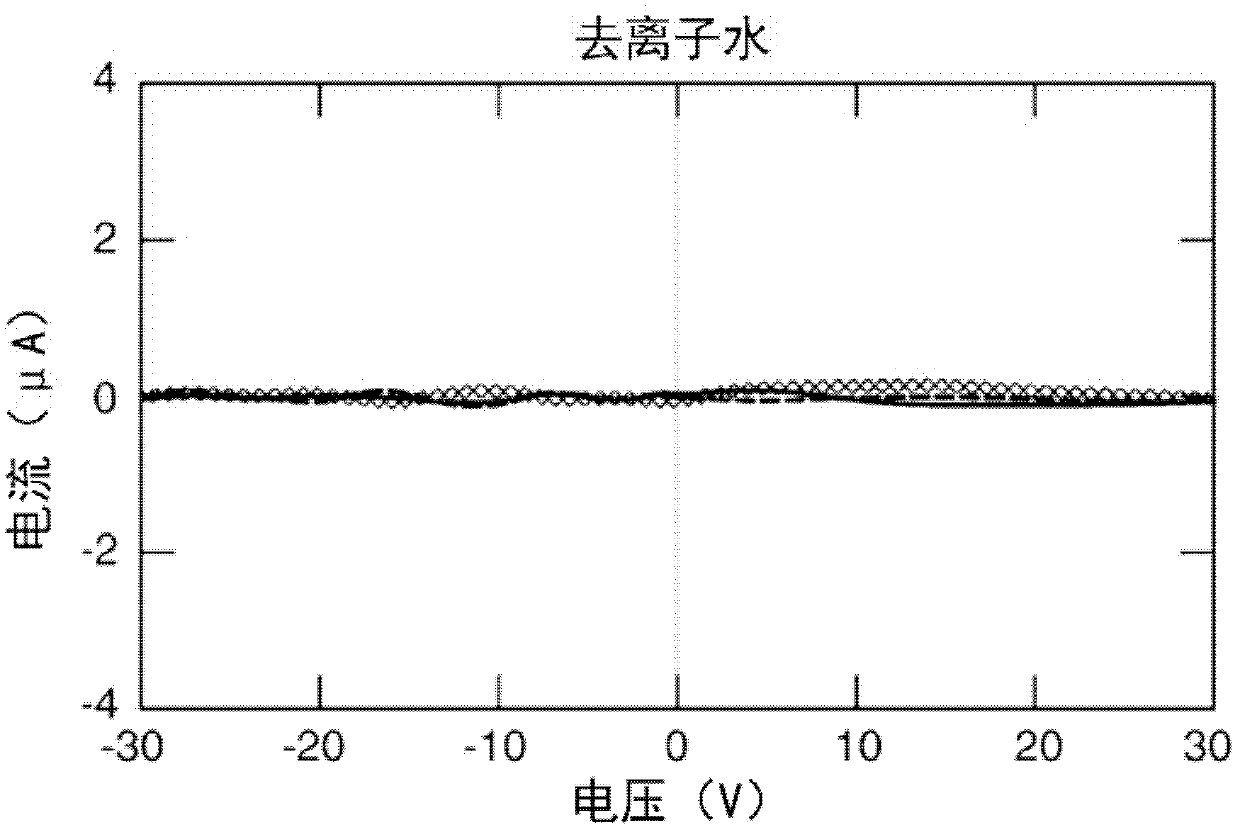

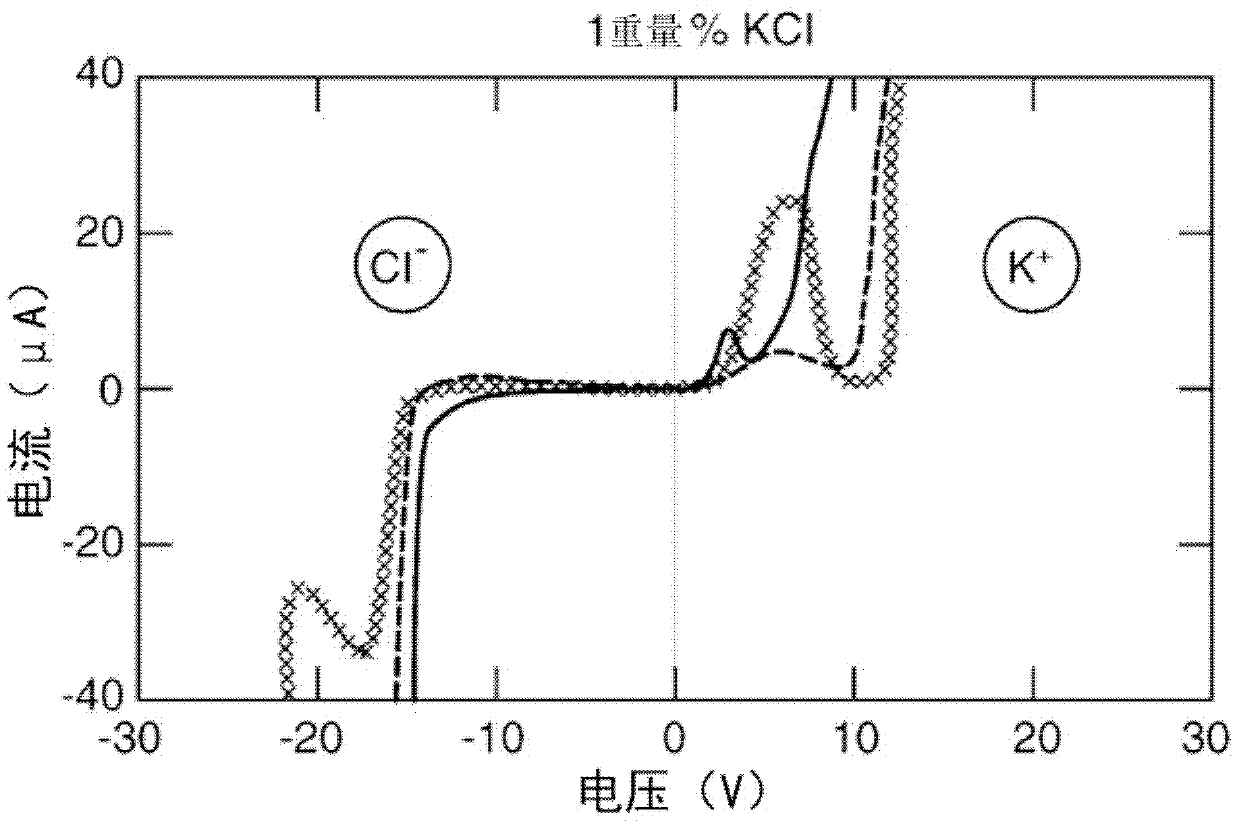

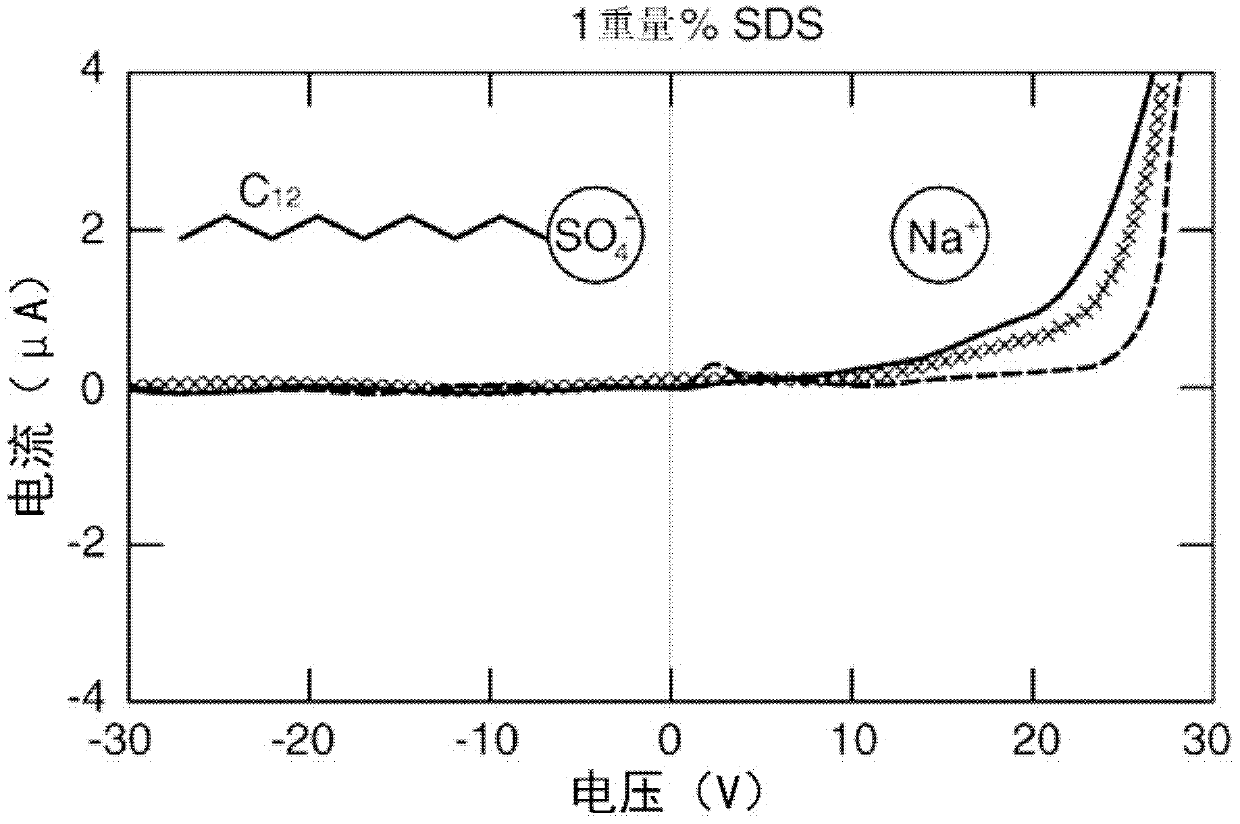

[0104] Prepare 1% potassium chloride (KCl) solution, sodium dodecyl sulfate (SDS) solution, and dodecyltrimethylammonium chloride (DTAC) solution in deionized water, respectively. Prepared according to the method described in "Ion and Liquid Dependent Dielectric Failure in Electrowetting Systems (Balaji Raj, Manjeet Dhindsa, Neil R. Smith, Robert Laughlin, and Jason Heikenfeld, Langmuir | 3b2 | Volume 9 | 13 / 8 / 09)" and Anion-purifying surfactant dodecyltrimethyloctanesulfonate (DTA-OS, dodecyltrimethylammonium octanesulfonate), the content of which is incorporated herein by reference in its entirety. Prepare a 0.05 wt% DTA-OS solution in deionized water. The conductivity of the solution is shown in Table 1 below.

[0105] Table 1: Conductivity results from dielectric breakdown experiments

[0106] the solution

[0107] 100nm Al according to the above procedure 2 o 3 and 50nm Cytop substrate to complete the dielectric breakdown experiment. Experimental results su...

Embodiment 2

[0109] A 0.013% sodium dodecyl sulfate (SDS) solution was prepared in deionized water. The solutions were tested for dielectric breakdown on substrates of different thicknesses of Parylene C substrates (one with 300 nm Parylene C, one with 700 nm Parylene C). like Figure 2A and 2B As shown, due to the small Na + cation, breakdown was observed with a positive DC voltage applied to thinner dielectrics. This demonstrates the importance of ion selection to allow the use of thin dielectrics in electrowetting devices to operate at low voltages.

Embodiment 3

[0111]0.013% and 1% sodium dodecyl sulfate (SDS) solutions were prepared in deionized water. The solutions were tested for dielectric breakdown on a 300 nm parylene HT substrate. like Figure 3A and 3B As shown, under positive DC voltage, no dielectric breakdown was observed for low concentration SDS solutions while high concentration solutions caused breakdown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com