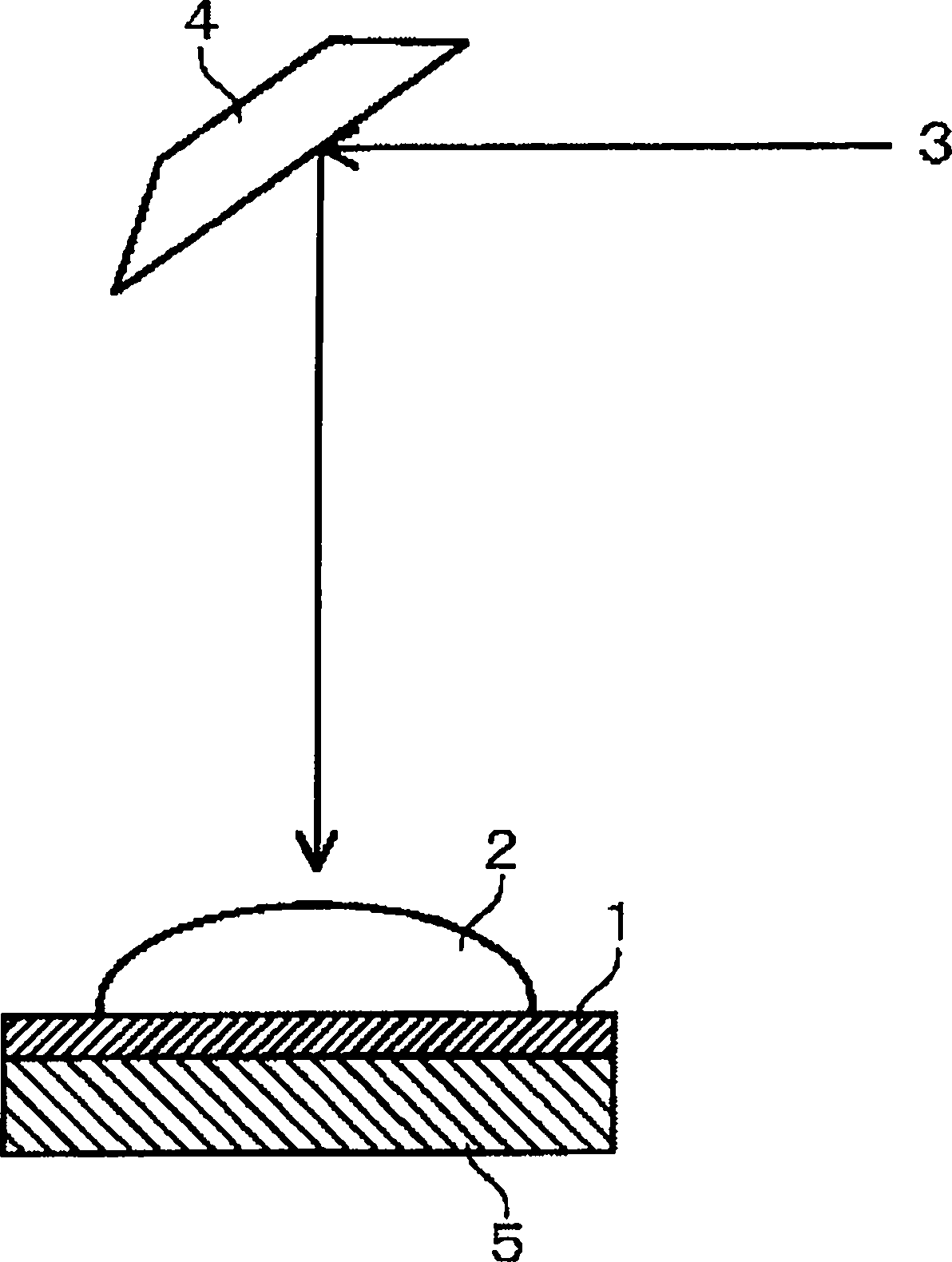

Coating material composition for liquid immersion exposure apparatus, laminate, method for forming laminate, and liquid immersion exposure apparatus

A technology of liquid immersion exposure and coating materials, which is applied in photolithography process exposure devices, microlithography exposure equipment, optics, etc., can solve the problem of not knowing water repellent materials, etc., achieve excellent durability and reduce the number of maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~34、 comparative example 1、2

[0062] [Manufacture of water-repellent composition (perfluoropolymer solution)]

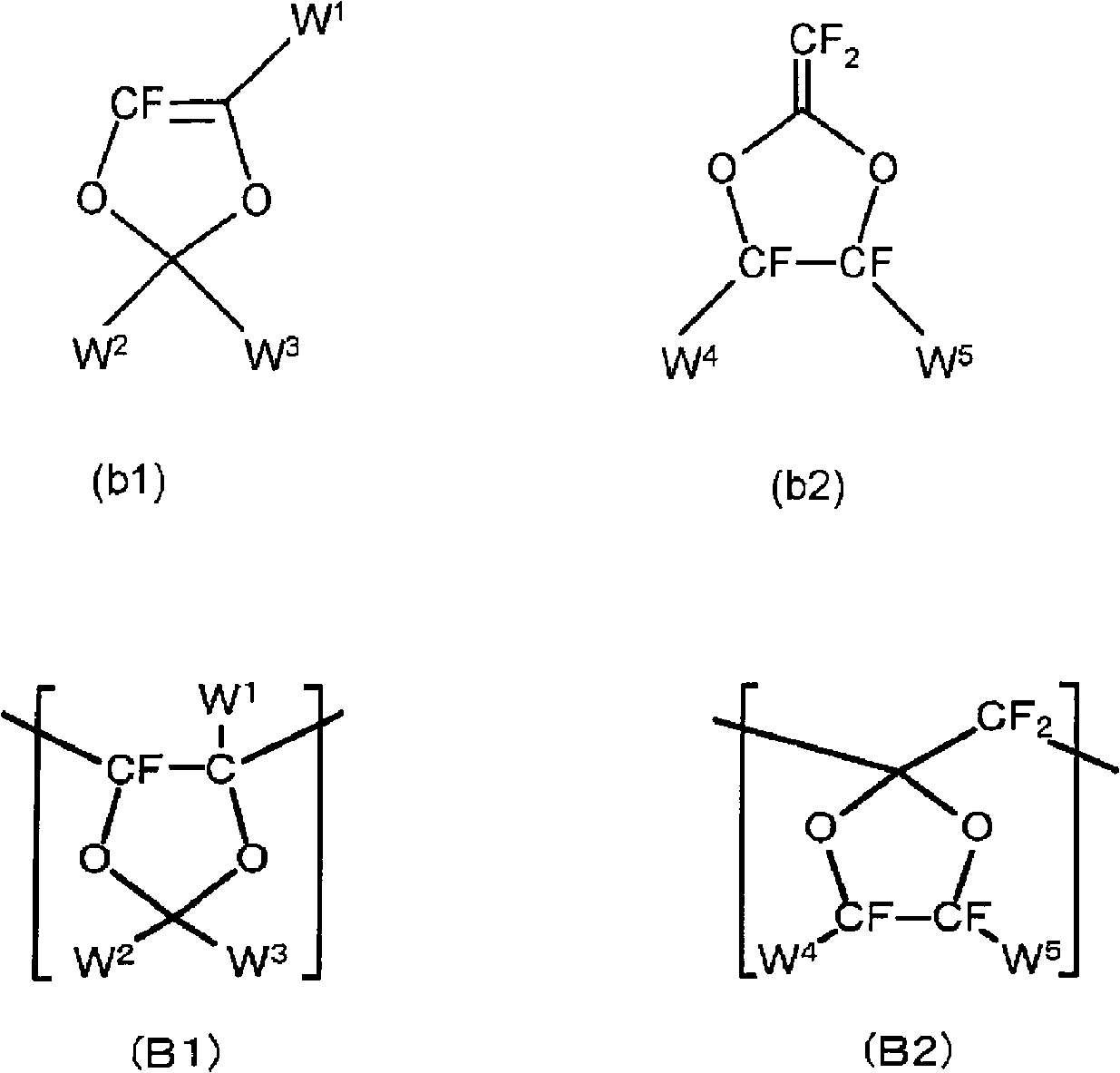

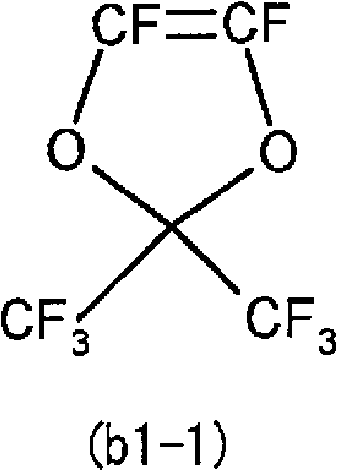

[0063] Make the fluorine-containing monomer (A, B, E, F, I, O) represented by formula A, B, E, F, I, O shown below with the composition (molar ratio) shown in Table 1 and other Monomer components (TFE, BVE, PPVE) were copolymerized to synthesize perfluoropolymer No.1, No.2, No.4, No.8, No.10, No.14~No.17 and No.24 respectively . TFE stands for tetrafluoroethylene, BVE stands for perfluorobutenyl vinyl ether, and PPVE stands for perfluoropropyl vinyl ether.

[0064] The synthesis of perfluoropolymer No.2, No.16, No.17 and No.24 was carried out as follows. Add 0.8g of fluorine-containing monomer A, I or O, 0.8g of other monomer components BVE or PPVE, and 0.08g of 1H-perfluorohexane as a solvent into a pressure-resistant container, and then add 0.34g of bisperoxide (Heptafluorobutyryl) (PFB) was used as a polymerization initiator. Bis(heptafluorobutyryl) peroxide (PFB) was added as a 3% by mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com