Rose jam and preparation method thereof

A technology of rose jam and rose, which is applied in the direction of food preparation, application, food science, etc., can solve the problems of long production time, flavor influence, sticky jam, etc., and achieve the goal of improving product texture, coordinating sweet and sour taste, and increasing nutrition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

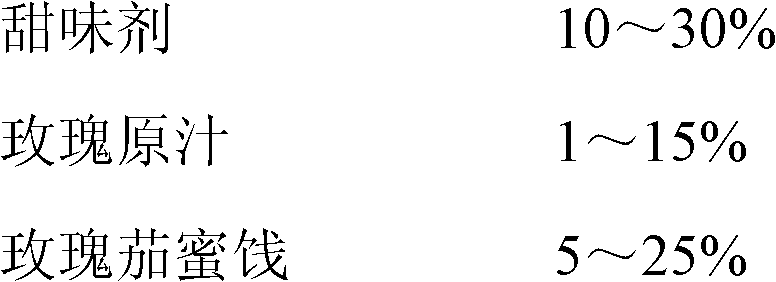

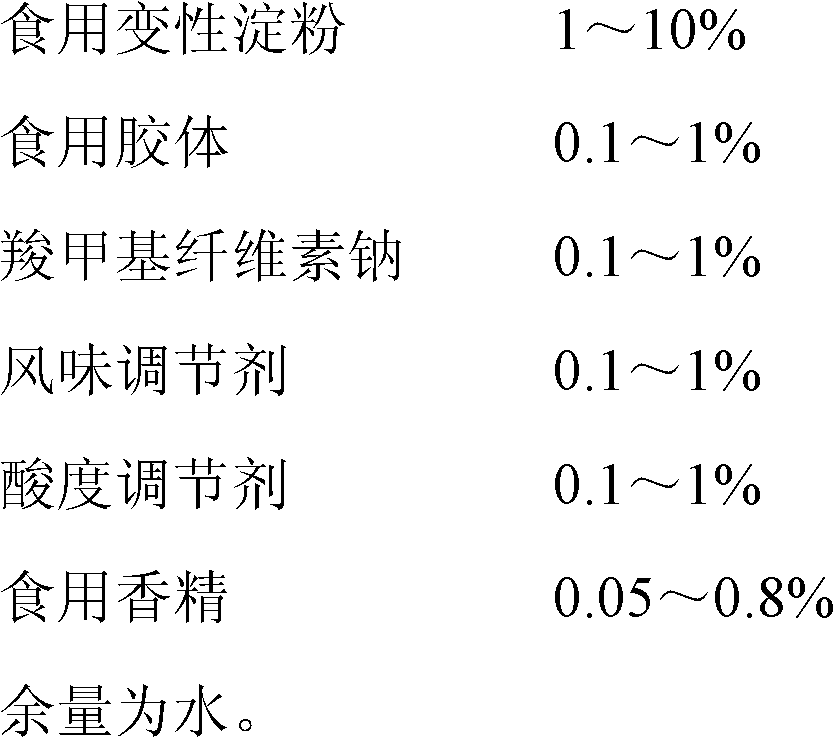

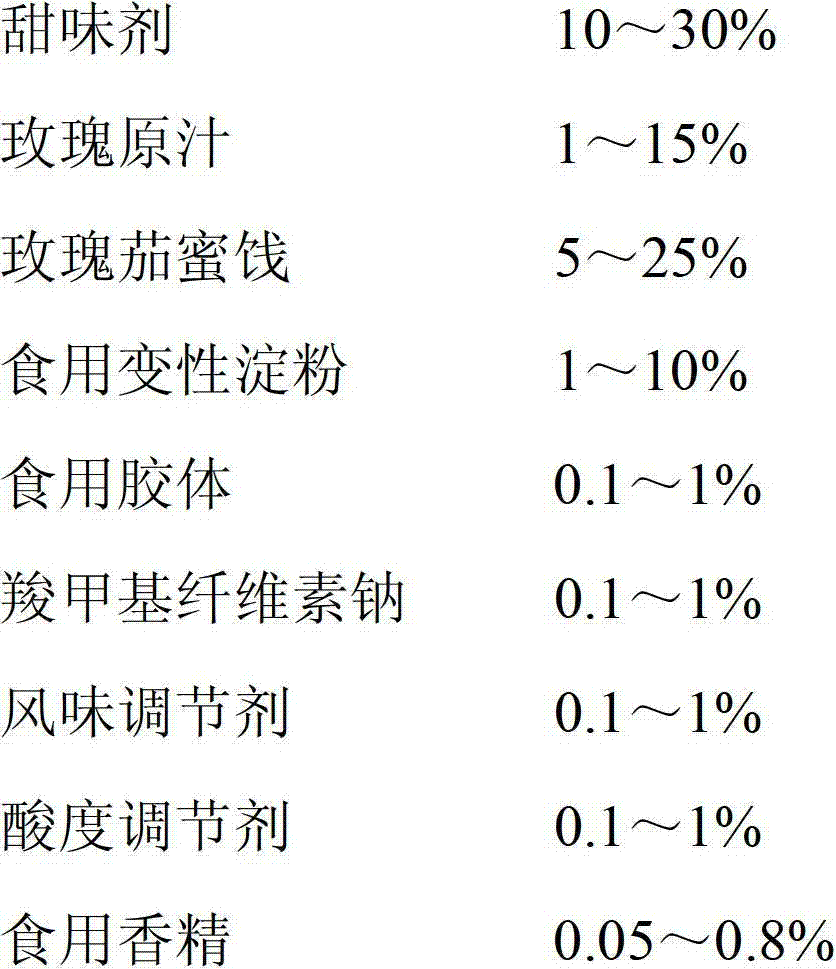

Method used

Image

Examples

Embodiment 1

[0039] (1) Cut candied roselle candied fruit into granules to obtain candied roselle candied granules with a size of 0.2cm×0.2cm;

[0040] (2) Prepare 0.8 g of citric acid with water into an acidity adjusting solution with a mass percentage concentration of 10%;

[0041] (3) Weigh 30g white granulated sugar, 5g acetylated distarch phosphate, 1g pectin, 1g sodium carboxymethylcellulose, 0.3g sodium citrate and 5g rose juice (concentration factor is 10), add 60g water, Stir while heating until the edible modified starch is completely gelatinized;

[0042] (4) Add 8g of acidity regulator, 15g of candied roselle candied granules and 0.6g of rose flavor, then add the remaining water to make the volume up to 200g;

[0043] (5) Continue to cook and stir until the solid content reaches 30% and stop cooking;

[0044] (6) High temperature filling;

[0045] (7) Sterilize in boiling water for 10 minutes;

[0046] (8) Cool to 28°C to obtain rose jam.

[0047] The rose jam obtained in this example has ...

Embodiment 2

[0049] (1) Cut the candied roselle candied fruit into granules to obtain the candied roselle candied granule with a size of 0.2cm×0.2cm;

[0050] (2) 0.4g of citric acid and 0.4g of malic acid are prepared into an acidity adjusting solution with a mass percentage concentration of 10% with water;

[0051] (3) Weigh 35g white granulated sugar, 4g hydroxypropyl distarch phosphate, 1g pectin, 0.5g gelatin, 1g sodium carboxymethyl cellulose, 0.3g sodium citrate and 8g rose juice (concentration factor is 25) , Add 70g of water, stir while heating until the edible modified starch is completely gelatinized;

[0052] (4) Add 8g acidity regulator, 20g candied roselle candied fruit and 0.6g rose flavor, then add the remaining water to make the volume 220g;

[0053] (5) Continue to cook and stir until the solid content reaches 40% and stop cooking;

[0054] (6) High temperature filling;

[0055] (7) Sterilize in boiling water for 15 minutes;

[0056] (8) Cool to 30°C to obtain rose jam.

[0057] The ...

Embodiment 3

[0059] (1) Cut candied roselle candied fruit into granules to obtain candied roselle candied granules with a size of 0.2cm×0.2cm;

[0060] (2) Prepare 0.8 g of malic acid with water into an acidity adjustment solution with a mass percentage concentration of 10%;

[0061] (3) Weigh 40g white granulated sugar, 5g hydroxypropyl starch ether, 1g pectin, 0.5g gelatin, 0.5g sodium carboxymethyl cellulose, 0.3g sodium citrate and 10g rose juice (the concentration factor is 15), Add 80g of water and stir while heating until the edible modified starch is completely gelatinized;

[0062] (4) Add 8g acidity regulator, 25g candied roselle candied granules and 0.6g rose flavor, then add the remaining water to make the volume 250g;

[0063] (5) Continue to cook and stir until the solid content reaches 45% and stop cooking;

[0064] (6) High temperature filling;

[0065] (7) Sterilize in boiling water for 12 minutes;

[0066] (8) Cool to 32°C to obtain rose jam.

[0067] The rose jam obtained in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com