Halogen-free phosphate-free high-heat-resistance thermosetting resin composition as well as bonding sheet and copper clad laminate prepared from same

A resin composition, high heat resistance technology, applied in the direction of epoxy resin glue, film/sheet adhesive, adhesive, etc., can solve the problems of non-adhesive force, high resin brittleness, etc., achieve low cost, high heat Decomposition temperature, effect of good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

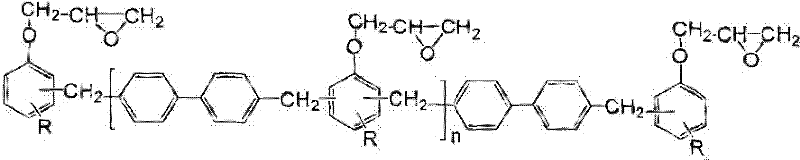

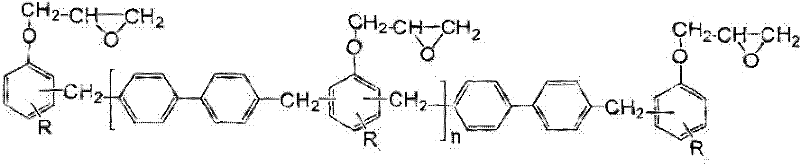

Method used

Image

Examples

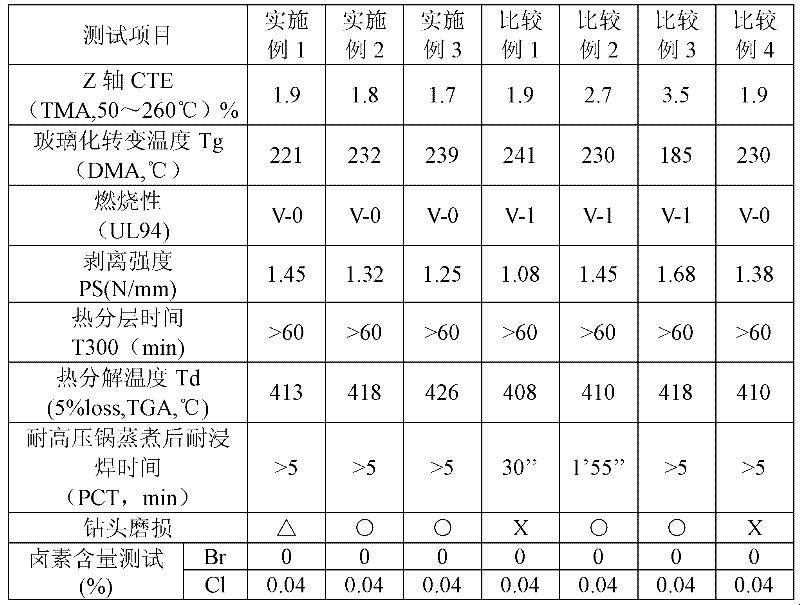

Embodiment 1

[0045] Add 25g of diaminodiphenylmethylether (DDE) and 200g of diphenylmethane bismaleimide (BDM) into a three-necked flask, start stirring, react at a constant temperature of 150°C for 50 minutes under condensing and reflux, and cool to room temperature to obtain Viscous liquid resin. In this resin solution, add 150g of biphenyl epoxy, 1.0g of dicyandiamide curing agent, 0.4g of catalyst 2-methyl-4-ethylimidazole, 20g of core-shell structure flexible components, and then add 60g of aluminum hydroxide , after 80 g of fused silicon dioxide and an appropriate amount of solvent N, N-dimethylformamide, adjust the solid content to 65%, and then stir and mix evenly.

[0046] After impregnating the above resin solution with glass cloth, bake it in an oven at 155° C. for 6 minutes to obtain a semi-cured adhesive sheet. Stack 8 adhesive sheets together, cover both sides with copper foil, and heat press in a vacuum press at 220°C for 90 minutes to obtain a copper-clad laminate (copper-...

Embodiment 2

[0048] Add 25 g of diaminodiphenylmethyl ether (DDE) and 260 g of diphenylmethane bismaleimide (BDM) into a three-necked flask, start stirring, react at a constant temperature of 150°C for 60 minutes under condensing and reflux, and cool to room temperature to obtain Viscous liquid resin. In this resin solution, add 120g of biphenyl epoxy, 1.0g of dicyandiamide curing agent, 0.35g of catalyst 2-methyl-4-ethylimidazole, 20g of core-shell structure flexible components, and then add 80g of aluminum hydroxide , after 60 g of fused silicon dioxide and an appropriate amount of solvent N, N-dimethylformamide, adjust the solid content to 65%, and then stir and mix evenly. Then a copper clad laminate was made according to the method in Example 1, and its properties are shown in Table 1.

Embodiment 3

[0050] Add 25 g of diaminodiphenylmethyl ether (DDE) and 300 g of diphenylmethane bismaleimide (BDM) into a three-necked flask, start stirring, react at a constant temperature of 150°C for 70 minutes under condensing and reflux, and cool to room temperature to obtain Viscous liquid resin. In this resin solution, add 100g of biphenyl epoxy, 1.0g of dicyandiamide curing agent, 0.3g of catalyst 2-methyl-4-ethylimidazole, 20g of core-shell structure flexible components, and then add 100g of aluminum hydroxide , after 40 g of fused silicon dioxide and an appropriate amount of solvent N, N-dimethylformamide, adjust the solid content to 65%, and then stir and mix evenly. Then a copper clad laminate was made according to the method in Example 1, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com