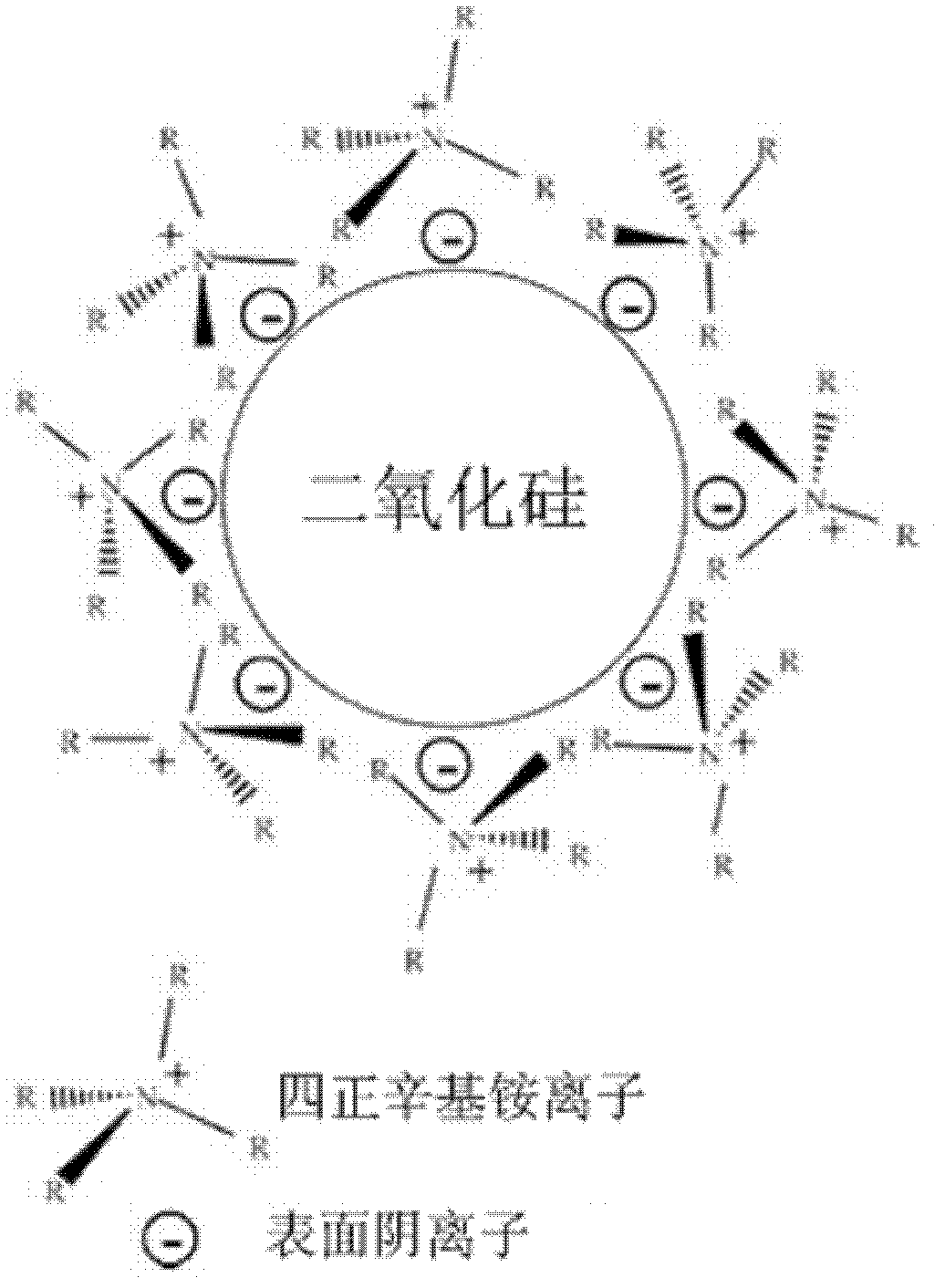

Nano silicon dioxide particle surface modifying method based on charge environment control and application thereof

A nano-silica, particle surface technology, applied in the field of nanomaterials, can solve the problems of difficult dispersion and infiltration, strong particle surface effect, easy agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

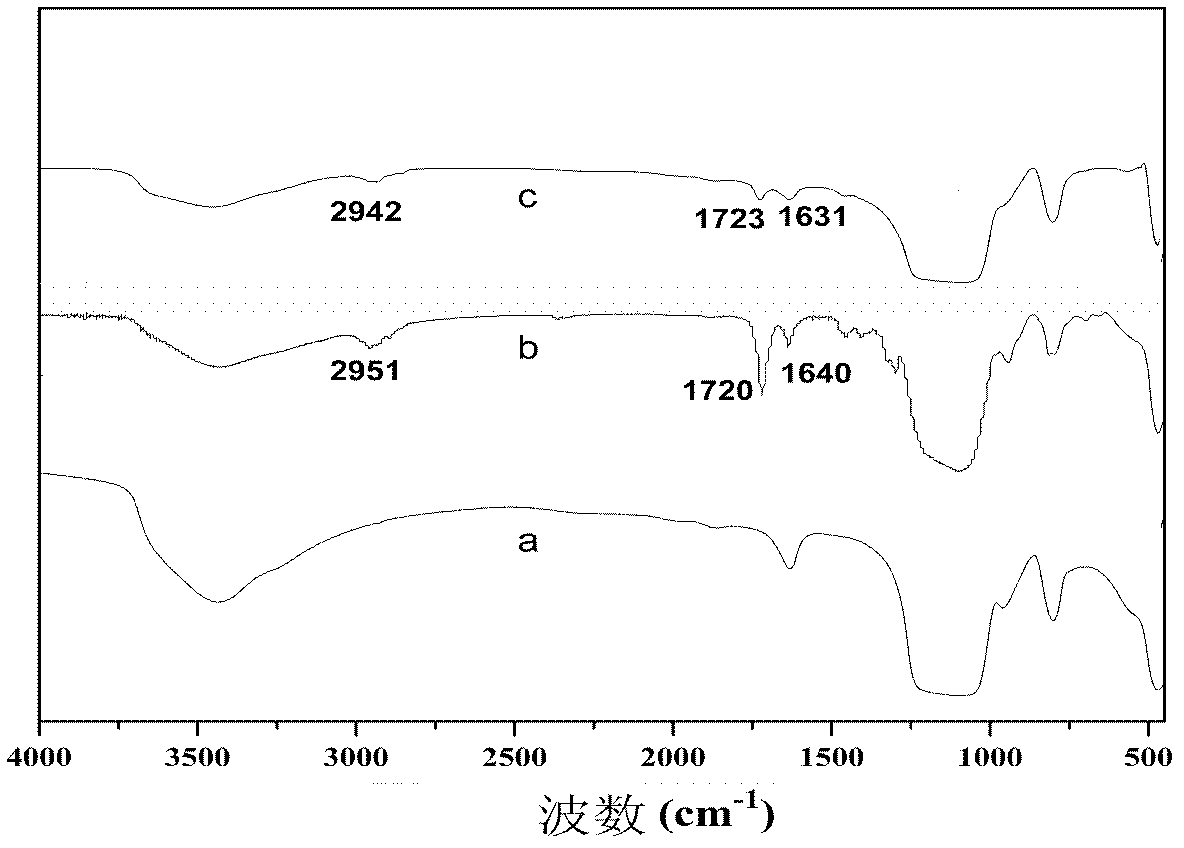

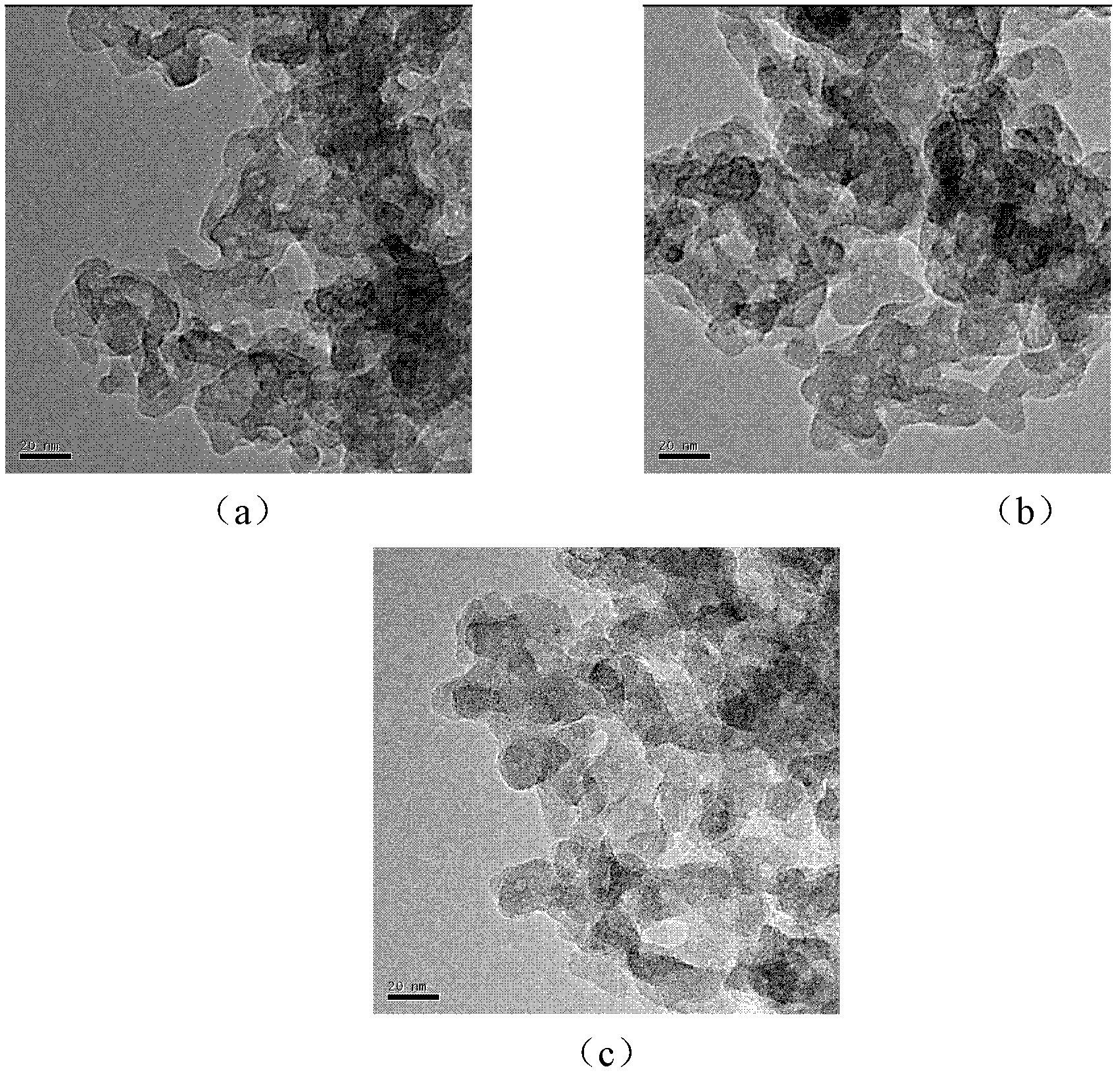

[0020] Weigh 5g SiO 2 Put it in a beaker, add it to the xylene solution of 0.75g tetra-n-octylammonium bromide, stir and disperse it with a glass rod, add 1.5ml of silane coupling agent KH-570, and use an ultrasonic pulverizer to prepare the suspension Ultrasonic dispersion. Pour the dispersed suspension into a three-necked flask, stir, heat up, and react at a constant temperature in a boiling state for 8 hours. The treated inorganic particle suspension was suction-filtered with a Buchner funnel, then extracted in a Soxhlet extractor for 48 hours with acetone as a solvent, and then dried in vacuum to obtain nano-SiO modified by KH-570 under the control of the charge environment. 2 , denoted as SiO 2 -KH570(TOAB).

Embodiment 2

[0022] Weigh 5g SiO 2 Put it in a beaker, add it to the xylene solution of 0.73g tetra-n-octylammonium bromide, stir and disperse it fully with a glass rod, add 1.5ml of silane coupling agent KH-570, and use an ultrasonic pulverizer to prepare the suspension Ultrasonic dispersion. Pour the dispersed suspension into a three-necked flask, stir, heat up, and react at a constant temperature in a boiling state for 8 hours. The treated inorganic particle suspension was suction-filtered with a Buchner funnel, then extracted in a Soxhlet extractor for 48 hours with acetone as a solvent, and then dried in vacuum to obtain nano-SiO modified by KH-570 under the control of the charge environment. 2 , denoted as SiO 2 -KH570(TOAB).

Embodiment 3

[0024] Weigh 5g SiO 2 Put it in a beaker, add it to the xylene solution of 0.76g tetra-n-octylammonium bromide, stir and disperse it with a glass rod, add 1.5ml of silane coupling agent KH-570, and use an ultrasonic pulverizer to prepare the suspension Ultrasonic dispersion. Pour the dispersed suspension into a three-necked flask, stir, heat up, and react at a constant temperature in a boiling state for 8 hours. The treated inorganic particle suspension was suction-filtered with a Buchner funnel, then extracted in a Soxhlet extractor for 48 hours with acetone as a solvent, and then dried in vacuum to obtain nano-SiO modified by KH-570 under the control of the charge environment. 2 , denoted as SiO 2 -KH570(TOAB).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com