Method for smelting lithium by vacuum aluminothermic reduction

An aluminothermic and vacuum technology is applied in the field of metallurgy to achieve good economic benefits, reduce pollution emissions, and the method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

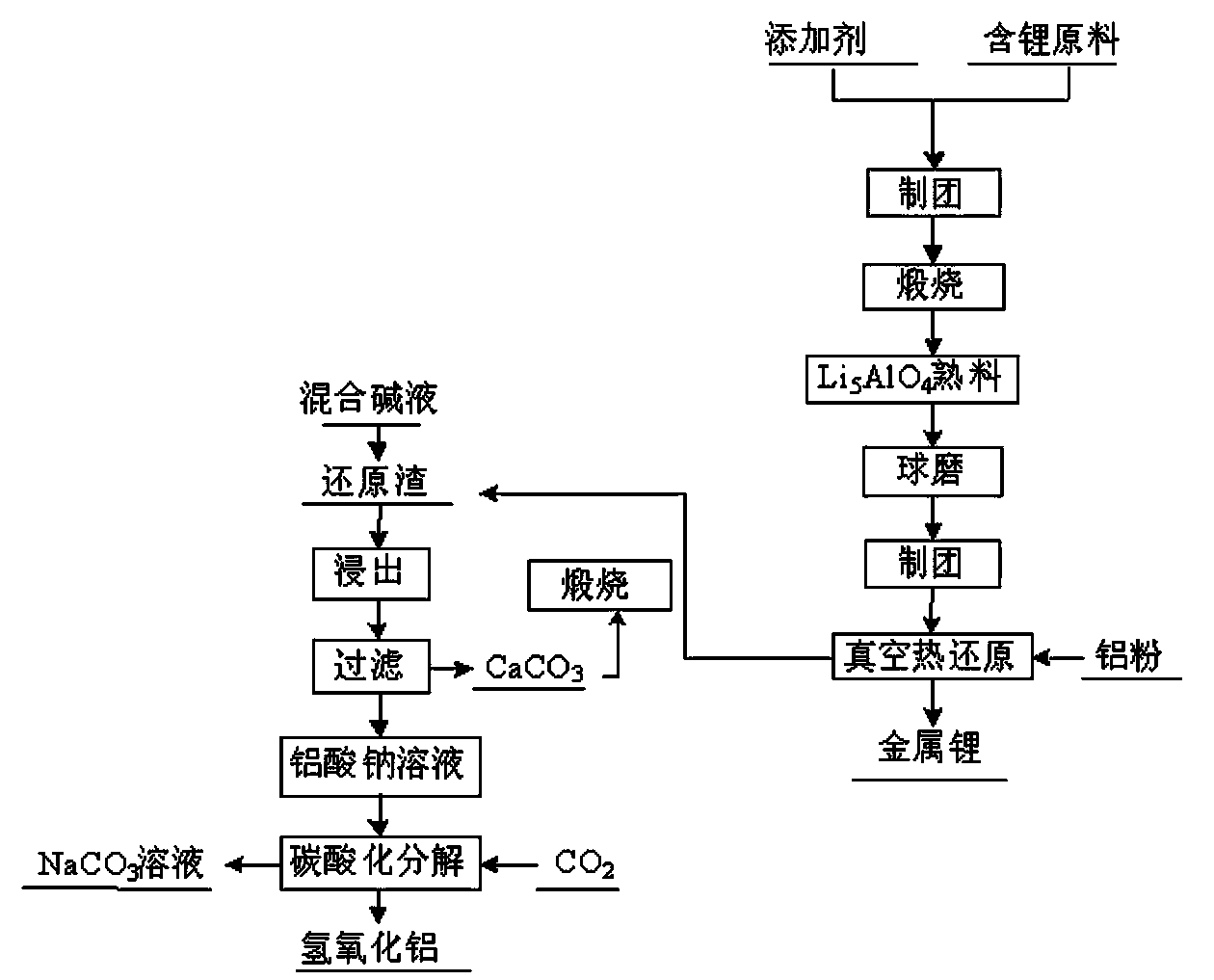

Image

Examples

Embodiment 1

[0041] Lithium-containing raw materials and additives are mixed to make pellets, and then calcined at 900-1100°C for 1.5h to obtain Li 5 AlO 4 Clinker; the lithium-containing raw material is lithium hydroxide, and the additive is a mixture of aluminum hydroxide and calcium oxide;

[0042] Will Li 5 AlO 4 The clinker is ball milled to a particle size of ≤80 μm, then mixed with aluminum powder and made into pellets, and then subjected to vacuum thermal reduction at an air pressure of ≤5Pa and a temperature of 1000~1200°C. The reaction time is 1.5h, and the generated lithium vapor crystallizes to form lithium metal. The remaining material is reducing slag;

[0043] The calcination reaction formula is:

[0044] 5LiOH·H 2 O+Al(OH) 3 = Li 5 AlO 4 +9H 2 O(1)

[0045] The vacuum thermal reduction reaction formula is:

[0046] 3Li 5 AlO 4 +4CaO+5Al=4[CaO Al 2 o 3 ]+15Li (5)

[0047] The molar ratio of lithium hydroxide, aluminum hydroxide and calcium oxide is 15:3:4, a...

Embodiment 2

[0058] Mix lithium-containing raw materials and additives to form pellets, and then calcinate at 900-1100°C for 2 hours to obtain Li 5 AlO 4 Clinker; the lithium-containing raw material is lithium hydroxide, and the additive is a mixture of aluminum hydroxide and calcium oxide;

[0059] Will Li 5 AlO 4 The clinker is ball milled to a particle size of ≤80 μm, then mixed with aluminum powder and made into pellets, and then subjected to vacuum thermal reduction at an air pressure of ≤5Pa and a temperature of 1000~1200°C. The reaction time is 2h, and the generated lithium vapor crystallizes to form lithium metal, and the remaining The material is reducing slag;

[0060] The calcination reaction formula is:

[0061] 5LiOH·H 2 O+Al(OH) 3 = Li 5 AlO 4 +9H 2 O(1)

[0062] The vacuum thermal reduction reaction formula is:

[0063] 21Li 5 AlO 4 +48CaO+35Al=4[12CaO 7Al 2 o 3 ]+105Li; (6)

[0064] The molar ratio of lithium hydroxide, aluminum hydroxide and calcium oxide ...

Embodiment 3

[0073] Lithium-containing raw materials and additives are mixed to make pellets, and then calcined at 900-1100°C for 3 hours to obtain Li 5 AlO 4 Clinker; the lithium-containing raw material is lithium hydroxide, and the additive is a mixture of aluminum hydroxide and calcium oxide;

[0074] Will Li 5 AlO 4 The clinker is ball-milled to a particle size of ≤80 μm, then mixed with aluminum powder and made into pellets, and then subjected to vacuum thermal reduction at an air pressure of ≤5Pa and a temperature of 1000-1200°C. The reaction time is 3 hours, and the generated lithium vapor crystallizes to form lithium metal, and the remaining The material is reducing slag;

[0075] The calcination reaction formula is:

[0076] 5LiOH·H 2 O+Al(OH) 3 = Li 5 AlO 4 +9H 2 O(1)

[0077] The vacuum thermal reduction reaction formula is:

[0078] 3Li 5 AlO 4 +4CaO+5Al=4[CaO Al 2 o 3 ]+15Li (5)

[0079] The molar ratio of lithium hydroxide, aluminum hydroxide, calcium oxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com