Method for preparing metallized carbon nanotube cathode by electrophoretic deposition in assistance of magnetic field

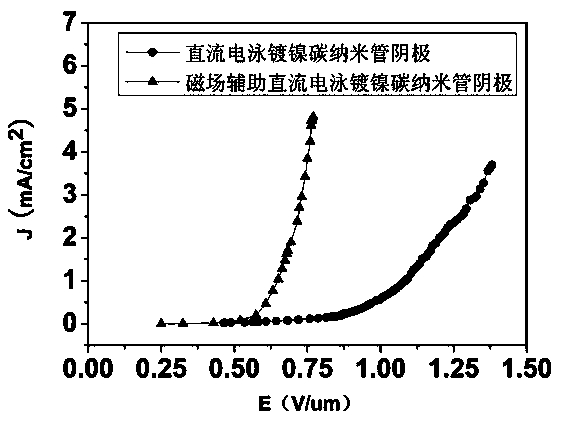

A technology of electrophoretic deposition and metallized carbon, which is applied in the manufacture of discharge tubes/lamps, cold cathodes, and electrode systems. It can solve the problem of low adhesion between carbon nanotubes and substrates, and increase the emission of cutting-edge electrons. ability, increase stability, and reduce the effect of reunion chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

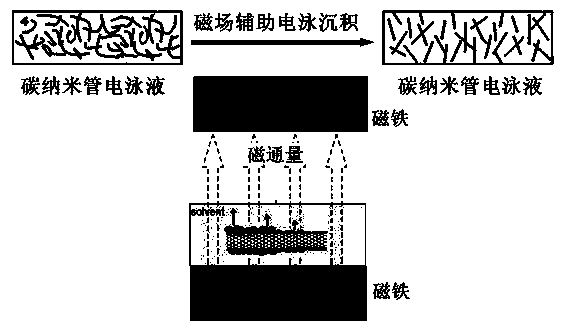

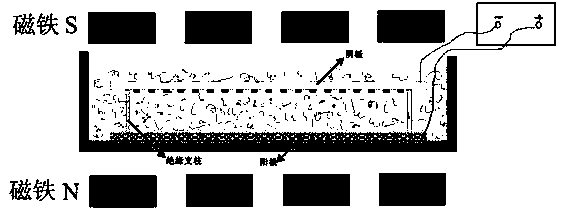

[0018] This embodiment provides a method for preparing a nickel-coated carbon nanotube cathode on a surface assisted by electrophoretic deposition. The following will be described in combination with specific implementation steps. figure 1 Schematic diagram of deposition of metallized carbon nanotube cathodes for magnetic field-assisted electrophoresis

[0019] 1) Pretreatment of carbon nanotubes before electrophoresis

[0020] (1) Purify, sensitize, and activate carbon nanotubes;

[0021] (2) A uniform magnetic metal nickel layer is deposited on the surface of carbon nanotubes by electroless plating;

[0022] 2) Preparation of carbon nanotube electrophoretic fluid

[0023] Preparation of organic slurry: first take ethyl cellulose ([C 6 h 7 o 2 (OC 2 h 5 ) 3 ] n ) 10 g, terpineol (C 10 h 18 O) 500 mL and 2 g of polyvinylpyrrolidone were mixed together at a temperature of 80 °C, and stirred by magnetic heating for 4 h, so that various materials were evenly mixed. ...

Embodiment 2

[0028] This embodiment provides a method for preparing a carbon nanotube cathode coated with an iron-cobalt composite magnetic metal layer on the surface by magnetic field-assisted pulse electrophoretic deposition. The following will be described in combination with specific implementation steps.

[0029] 1) Pretreatment of carbon nanotubes

[0030] (1) Purify, sensitize, and activate carbon nanotubes;

[0031] (2) A uniform iron-cobalt composite magnetic metal layer is deposited on the surface of carbon nanotubes by evaporation coating method.

[0032] 2) Preparation of carbon nanotube electrophoretic fluid

[0033] Get the carbon nanotube of 50 mg surface plating iron-cobalt composite magnetic metal layer and 25mg magnesium nitrate hexahydrate (Mg(NO 3 )·6H 2 O) Disperse in 250ml of isopropanol, and ultrasonically disperse in an ultrasonic cell pulverizer for 1 hour to obtain a uniform surface metallized carbon nanotube dispersion (0.2mg / ml).

[0034] 3) Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com