Preparation method for positive plate of lithium-sulfur battery

A positive pole piece, lithium-sulfur battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as no research reports, and achieve the effect of improving cycle performance, excellent electrical conductivity, and electrode structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix elemental sulfur powder, conductive carbon black, and polyacrylic acid (PAA) at a mass ratio of 60:30:10, and disperse them in water of a certain mass (85wt% of the dry mass), and then coat them on an Al foil set. In terms of fluid, after drying, it is compressed to obtain a lithium-sulfur battery positive electrode sheet.

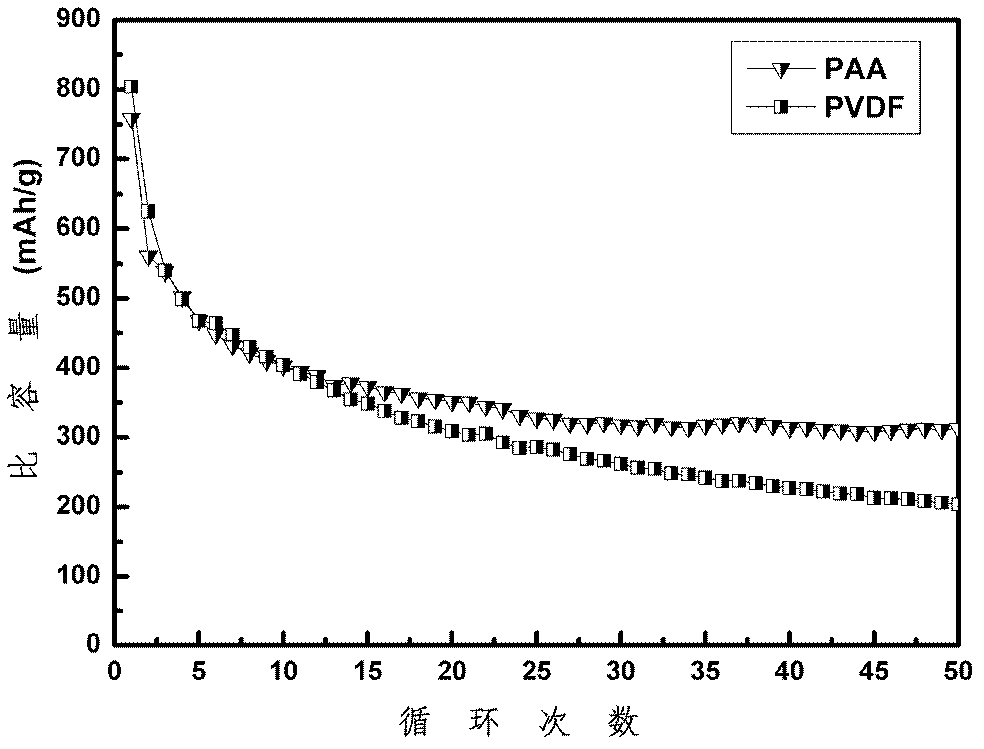

[0033] The battery assembly and testing are as follows: the positive electrode sheet is punched into an electrode sheet with a diameter of 10mm, the metal lithium sheet is used as the negative electrode, and the electrolyte is 1M LiTFSI / DOL:DME (1:1), assembled in a glove box filled with argon into a CR2025 button battery. Carry out constant current charge and discharge test at room temperature (25°C) at 0.2C, and the charge and discharge cut-off voltage is 1.5~3.0V. The specific capacity of the first discharge is 758mAh / g, and the specific capacity after 50 cycles is 313mAh / g. Using polyvinylidene fluoride (PVDF) as the binder, the first disc...

Embodiment 2

[0035] The elemental sulfur powder, conductive carbon black, and lithium polyacrylate (PAALi) were uniformly mixed according to the mass ratio of 60:33:7, and dispersed in a certain mass (90wt% of the dry mass) of water, and then coated on the Al foil set In terms of fluid, after drying, it is compressed to obtain a lithium-sulfur battery positive electrode sheet.

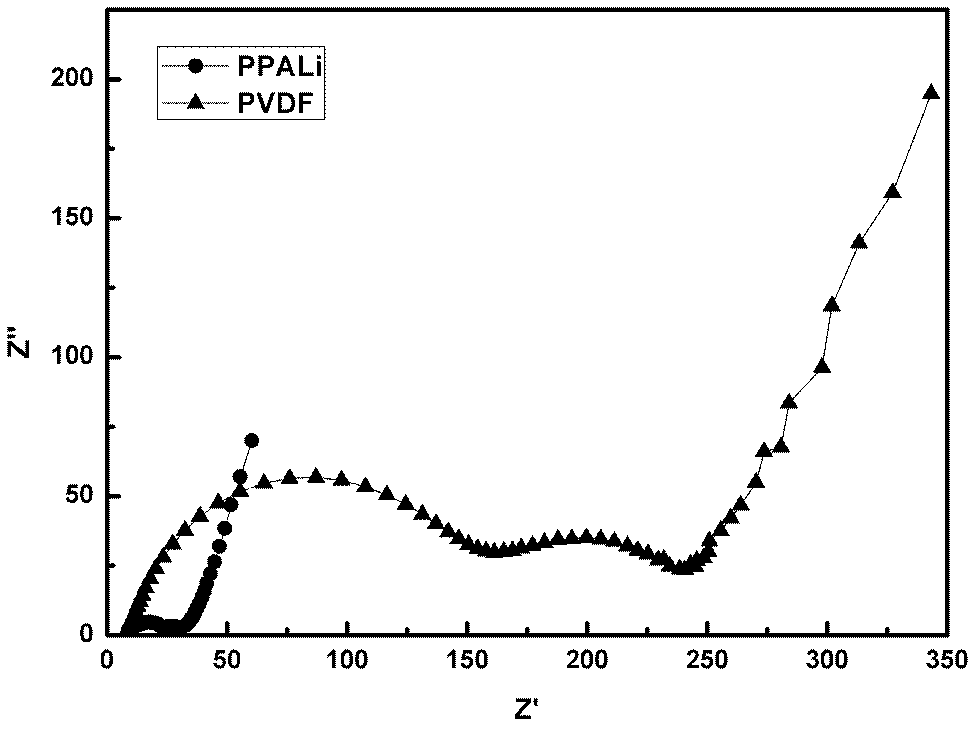

[0036] Cell assembly was the same as for testing and Example 1. After 50 cycles, the discharge specific capacity is 362mAh / g. Compared with polyvinylidene fluoride (PVDF), the impedance of the fresh battery and after 50 cycles is significantly reduced. Impedance spectrum after 50 cycles see figure 2 .

Embodiment 3

[0038] Mix sulfur-carbon nanotube composite material, carbon fiber, and polyacrylic acid (PAA) uniformly according to the mass ratio of 80:10:10, and disperse them in water with a certain mass (85wt% of the dry mass), and then coat them on Al foil On the current collector, dry and press to obtain a lithium-sulfur battery positive electrode sheet.

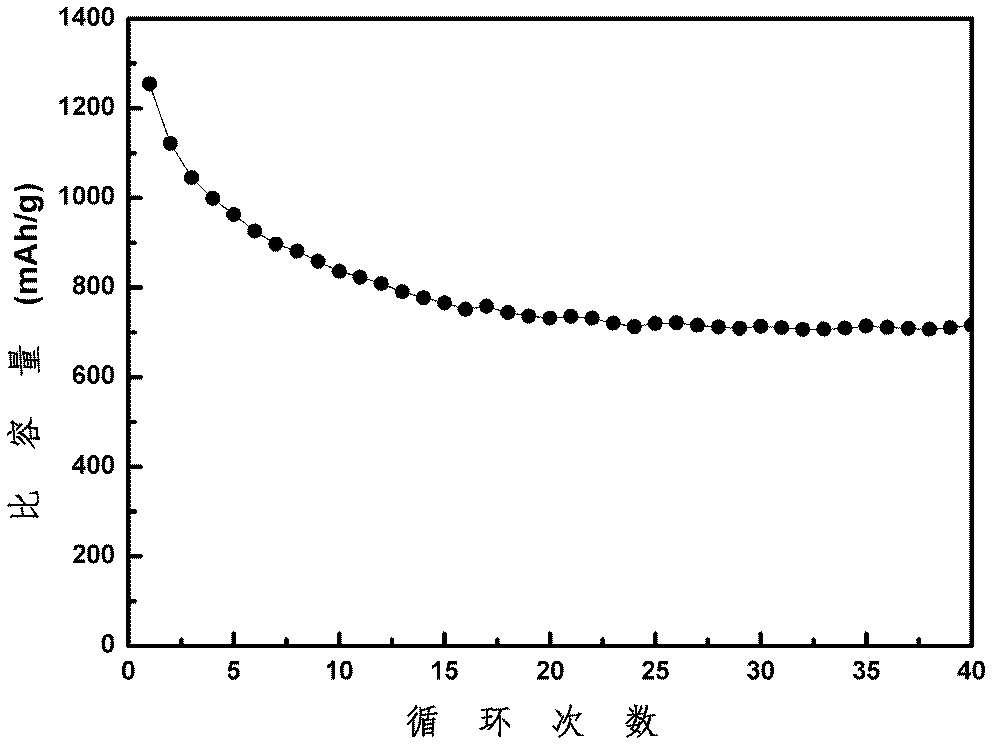

[0039] Battery assembly and testing are the same as in Example 1. The first discharge specific capacity is 1254mAh / g, and the battery discharge specific capacity remains at 716mAh / g after 40 cycles. image 3 It is the lithium-sulfur battery cycle performance curve obtained in Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com