Process for producing tea extract

A technology for extracts and teas, which is applied in the field of tea extracts to achieve the effects of rich aroma, enhanced aroma and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

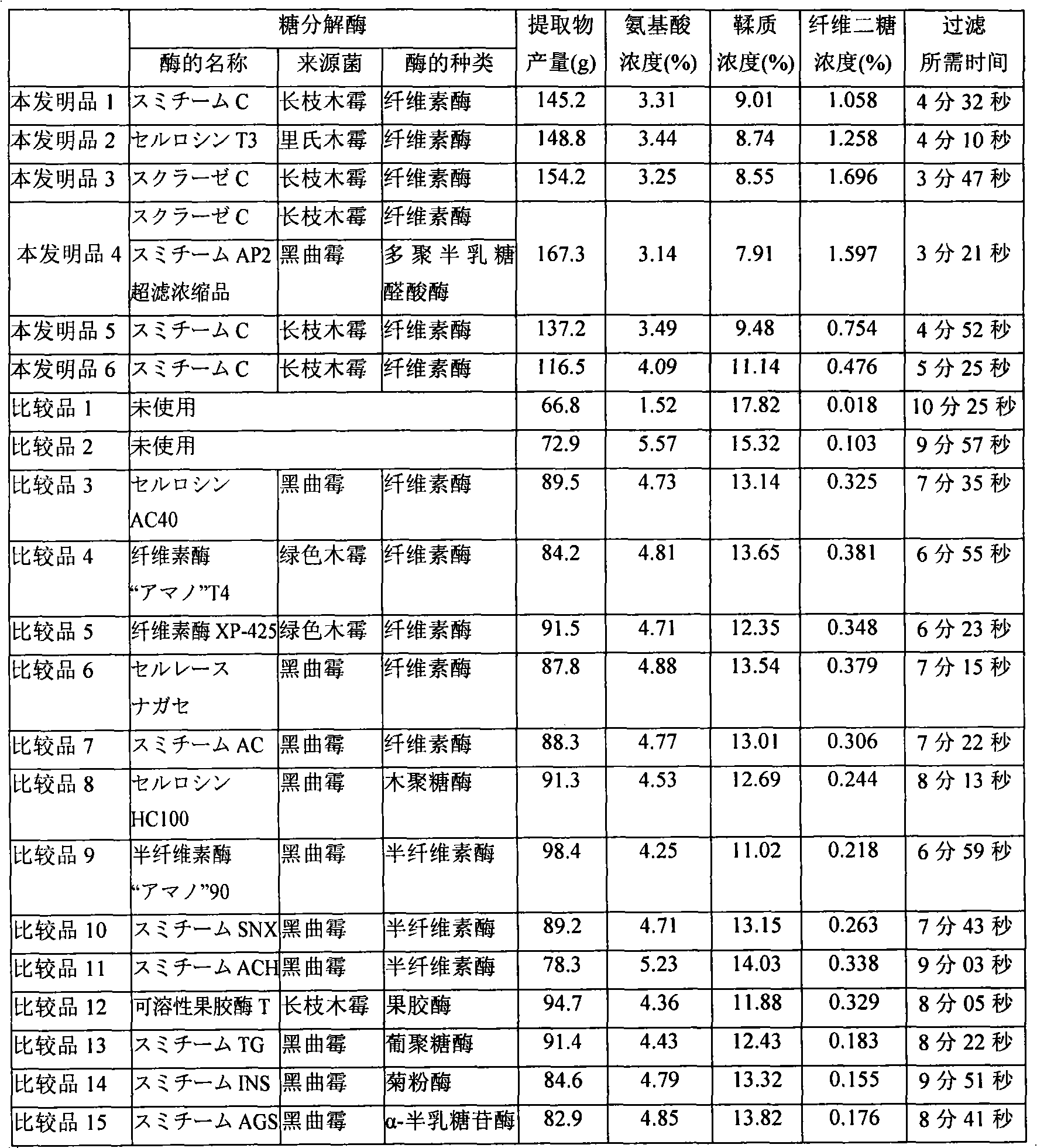

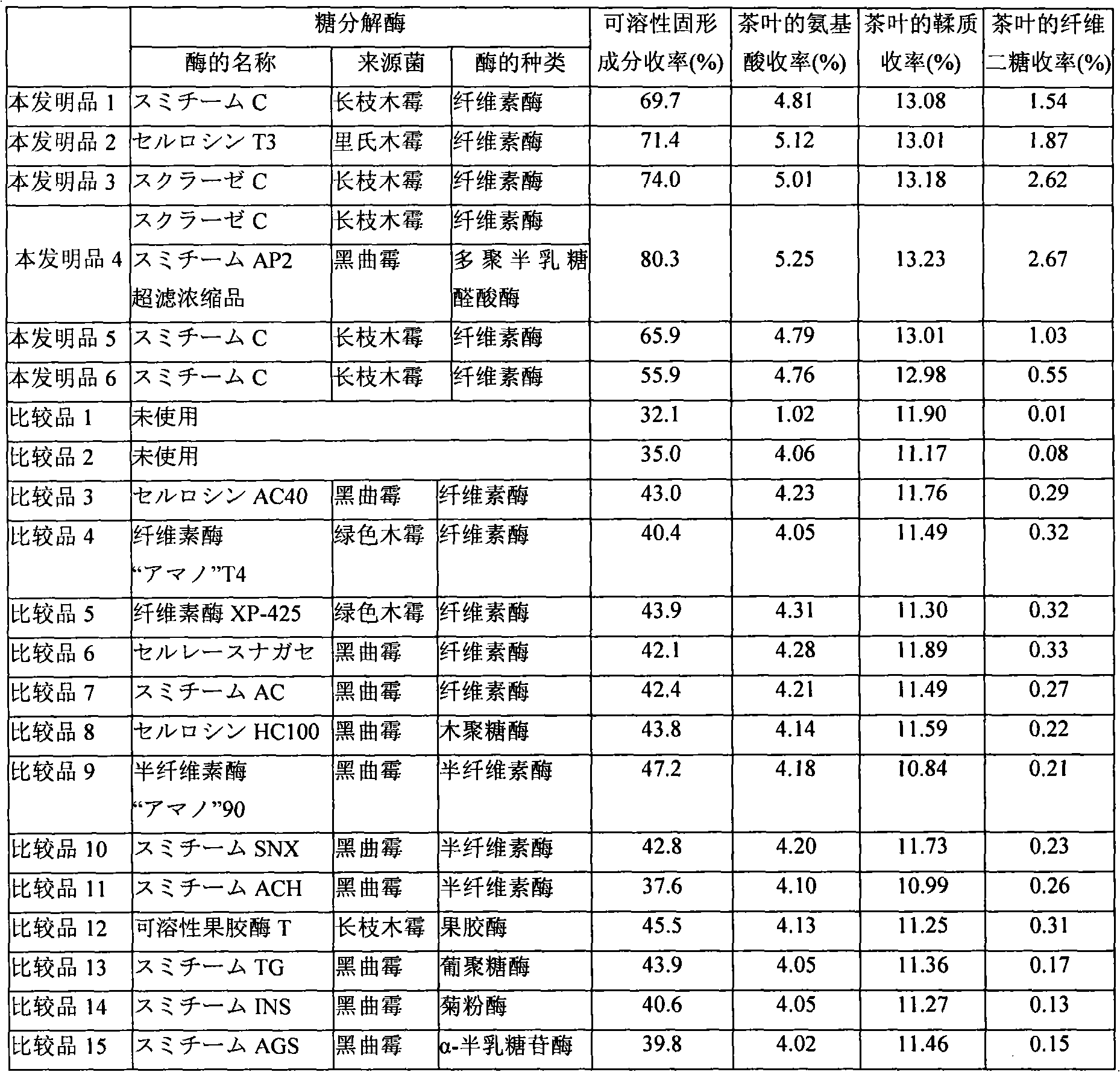

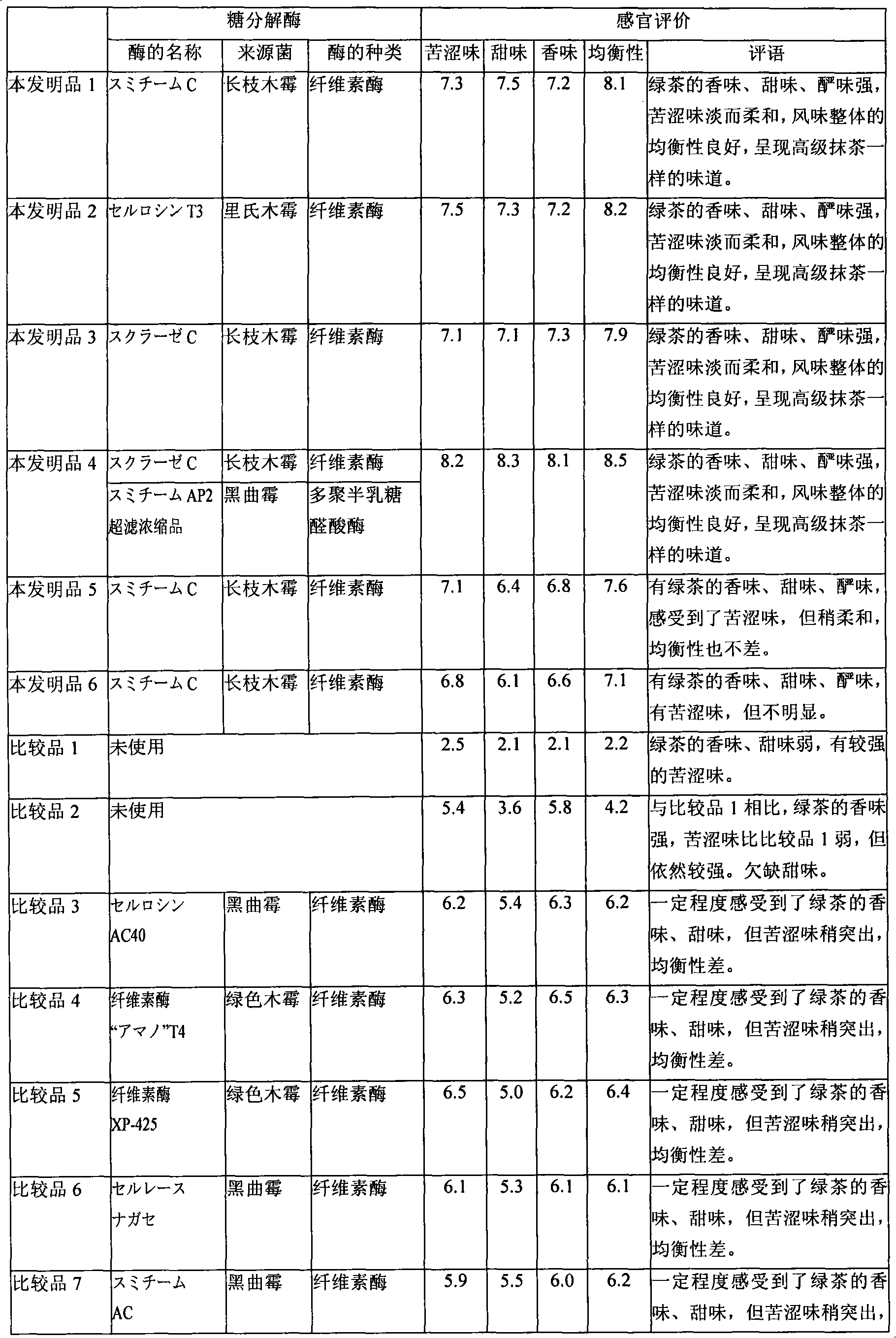

Examples

Embodiment 1

[0050] To a solution in which 0.6 g of sodium ascorbate was dissolved in 900 g of demineralized water was added 100 g of green tea leaves (manufactured in China by steam curing), sterilized at 80°C for 5 minutes, and cooled to 45°C. 1 g of tannase (manufactured by Mitsubishi Chemical Fuzz: 500 U / g) was added thereto, followed by stirring for 15 minutes. Then add 1 g of Protease M (manufactured by Amano Enzyme: 5500 U / g) and 0.25 g of Sumichimu C (1500 U / g of cellulase derived from Trichoderma longibrachia produced by Shin Nippon Chemical Industry), and carry out 8 days at 40°C after dissolving. hours of enzyme treatment.

[0051] After enzyme treatment, sterilize at 90°C for 10 minutes, cool to 30°C, remove the solid matter of tea residue with a bleaching cloth, and then use a vacuum suction filter pre-coated with 10g of cellulose powder on No. 2 filter paper (8cm) , carry out suction filtration with certain pressure (degree of reduced pressure 13.33KPa), obtain the extract l...

Embodiment 2

[0053] In Example 1, use 0.25g celrosin (registered trademark) T3 (cellulase from Trichoderma reesei prepared by Eiichibiyai: 2600U / g), instead of 0.25g Sumichim C, and perform the same procedure as in Example 1 except that Exactly the same operation (4 minutes and 10 seconds required for filtration) yielded 148.8 g of product 2 of the present invention.

Embodiment 3

[0055] In Example 1, use 0.25g Sukra-Zen C (cellulase from Trichoderma longibrachia produced by Mitsubishi Chemical Fuzu: 3000U / g), instead of 0.25g Sumi-C, in addition to carry out and implement Exactly the same operation as Example 1 (3 minutes and 47 seconds required for filtration) yielded 167.2 g of product 3 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com