Method for preparing shortening/margarine base stock oil commonly used by lard oil base

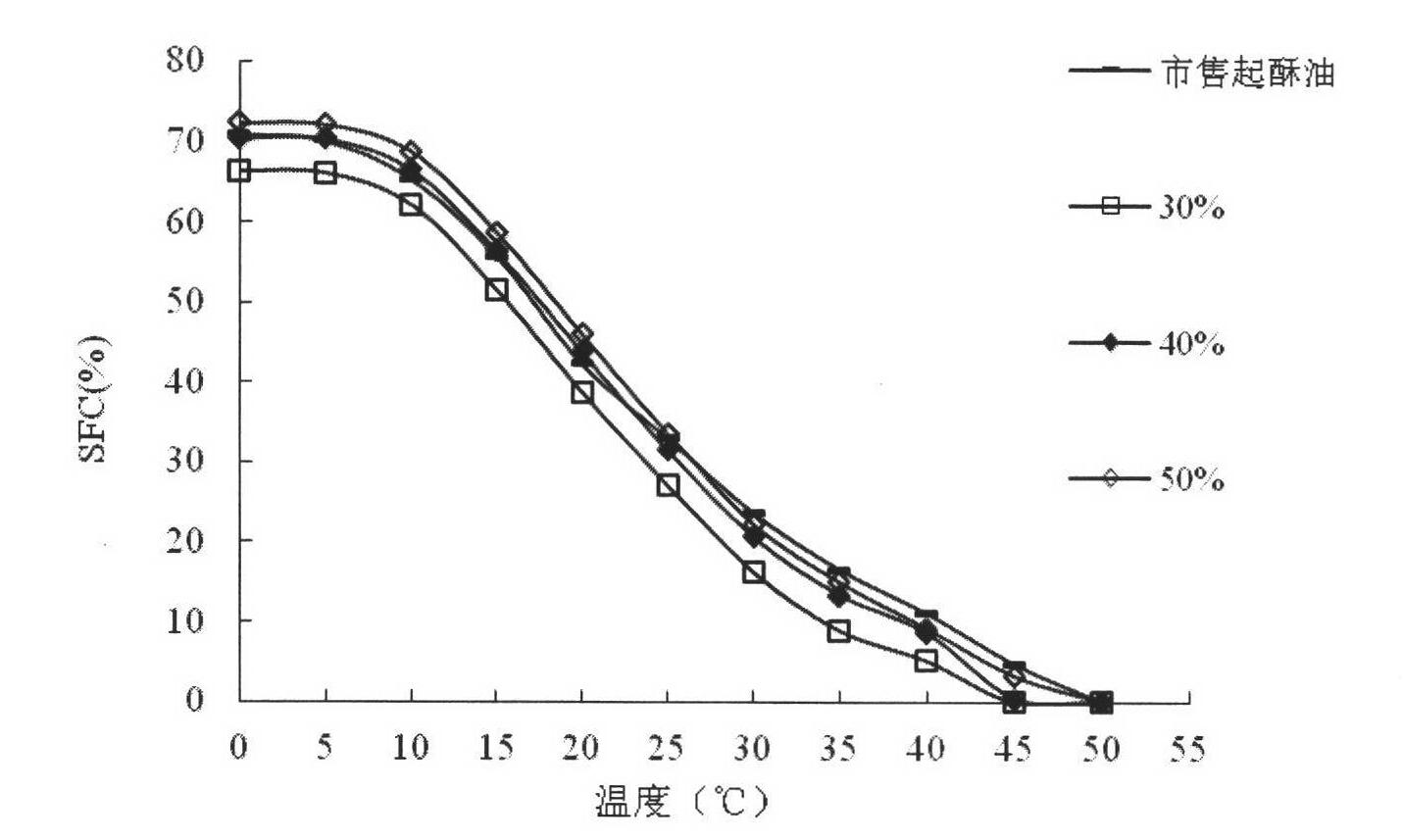

A margarine and shortening technology, which is applied in the directions of edible oil/fat, food preparation, cream substitutes, etc., can solve the problems of coarse and rough crystals, affecting a wide range of applications, poor caseinization, etc., and can expand the application range and SFC curve The effect of smooth, good machining characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: lard and 46 degree hydrogenated soybean oil prepare shortening base material oil

[0018] Accurately take by weighing 10g 46 degree hydrogenated soybean oil content and be respectively the mixture of lard and hydrogenated soybean oil of 20%, 30%, 40%, 50%, 60%, 70%, 80% in the round bottom flask, mix, Vacuum dehydration and degassing, then add immobilized lipase Lipozyme IM-20 1%, 3%, 5%, 7%, 9%, 11%, 13% (by oil weight), in rotary evaporation reactor (vacuum 0.09MPa, speed 80r / min), the reaction time is 0.5h, 1h, 1.5h, 2h, 3h, 4h, 5h, 6h, the temperature is 40°C, 50°C, 60°C, 70°C, 80°C , 90°C, under this condition, the whole test experiment was carried out. After the reaction was completed, the immobilized lipase was removed by suction filtration, and then the reactant was subjected to molecular distillation and purification to remove free fatty acid, and the transesterification product was obtained. Taking the solid fat content (SFC) and melting point o...

Embodiment 2

[0019] Embodiment 2: lard and extremely hydrogenated rapeseed oil prepare shortening base oil

[0020] Accurately take 10g of extremely hydrogenated rapeseed oil content and be respectively the mixture of 20%, 30%, 40%, 50%, 60%, 70%, 80% lard and extremely hydrogenated rapeseed oil in a round bottom flask, mix Uniform, vacuum dehydration and degassing, then add immobilized lipase Lipozyme IM-60 1%, 3%, 5%, 7%, 9%, 11%, 13% (by oil weight), in a rotary evaporation reactor (vacuum degree 0.09MPa, rotation speed 80r / min), the reaction time is 0.5h, 1h, 1.5h, 2h, 3h, 4h, 5h, 6h, the temperature is 40°C, 50°C, 60°C, 70°C, 80°C and 90°C, the full test experiment was carried out under these conditions. After the reaction was completed, the immobilized lipase was removed by suction filtration, and then the reactant was purified by molecular distillation to remove free fatty acids to obtain the transesterification product. Taking the solid fat content (SFC) and melting point of the p...

Embodiment 3

[0021] Embodiment 3: lard and 52 degree palm stearin prepare shortening base material oil

[0022] Accurately weigh 10g 52 degree palm stearin content and be respectively the mixture of 20%, 30%, 40%, 50%, 60%, 70%, 80% lard and palm stearin in a round bottom flask, mix well, Vacuum dehydration and degassing, then respectively add immobilized lipase Chirazyme L2 1%, 3%, 5%, 7%, 9%, 11%, 13% (by oil weight), in rotary evaporation reactor (vacuum degree 0.09 MPa, rotating speed 80r / min), the reaction time is 0.5h, 1h, 1.5h, 2h, 3h, 4h, 5h, 6h, the temperature is 40°C, 50°C, 60°C, 70°C, 80°C, 90°C ℃, under this condition, carry out the whole test experiment, after the reaction is finished, the immobilized lipase is removed by suction filtration, and then the reactant is purified by molecular distillation to remove the free fatty acid, and the transesterification product is obtained. Taking the solid fat content (SFC) and melting point of the product at 20°C and 25°C as indicator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com