Gradient-structured metal oxide and preparation method thereof

A gradient structure and oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, structural parts, etc., can solve the problems of limiting the performance of electrode materials, reducing material performance, and lack of power. Achieve the effect of improving electrochemical efficiency, improving performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

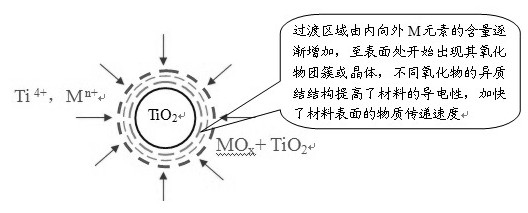

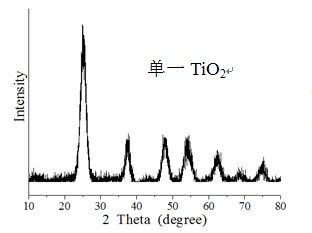

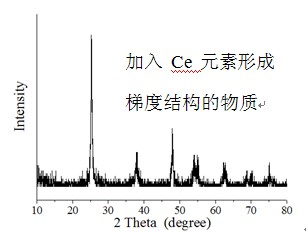

[0027] First, tetrabutyl titanate is used as raw material, after hydrolysis at room temperature for 2 hours, put into a 250ml three-necked flask, and react for three minutes under 700 watts of microwave power, at this time, TiO is formed in the solution. 2 as the core seed, and then gradually add the hydrolyzed CeCl to the reaction system 4 At this time, the content of Ce element in the growing crystal gradually increases from the inside to the outside, while the content of Ti element gradually decreases, finally forming nano-TiO 2 As the matrix, the gradient structure with increasing Ce element content gradually, CeCl 4 The dropping time of the hydrolyzate was controlled within 5 minutes, and finally a surface element distribution structure with an atomic ratio of Ti element and Ce element on the surface of 1:2 was formed. diagram 2-1 and Figure 2-2 single-phase TiO 2 And the XRD pattern of the material with Ce element to form a gradient distribution structure. The elec...

Embodiment 2

[0029] ZrOCl 2 It is the precursor of Zr. It is hydrolyzed at room temperature for 4 hours. During the hydrolysis process, a small amount of ammonia water can be added to control the pH value of the solution at about 10. At this time, ZrO is formed. 2 As the core seed crystal, the precursor solution was reacted under ultrasonic cavitation conditions, the ultrasonic power was 500W, and after three minutes of reaction, the injection pump was started to add pre-hydrolyzed TiCl 4 base precursor, the added TiCl 4 amount and ZrOCl 2 Equimolar amount, forming a gradient structure metal oxide with a gradually increasing ratio of Ti elements from the inside to the outside, TiCl 4 The addition time of the hydrolyzate is controlled within 3 to 5 minutes. After the addition is completed, continue ultrasonic cavitation for 20 minutes to obtain the designed ZrO 2 It is a substance with a gradient distribution of Ti element at the core, and the ratio of Ti element to Zr element on the sur...

Embodiment 3

[0031] With Ce(NO 3 ) 4 As a precursor, use ammonia water to adjust the pH value of the solution at about 12, pre-hydrolyze for 2 hours, put the hydrolyzed product into a 250ml three-necked flask, react for 2 minutes under 700W microwave and 300W ultrasonic conditions, and then start the injector to add 0.01 mol / liters of NH 4 F solution, NH 4 F solution was added within 5 minutes, NH 4 The molar ratio of the added molar amount of the F solution to the Ce element is 1:10, and the reaction is continued for 15 minutes to obtain CeO containing the F element. 2 Gradient structure oxide, CeO 2 The conductivity of the material is increased by about 20 times, and the ionic conductivity of the material is increased by about 10 times. As a methanol fuel cell catalyst, the polarization of the positive electrode is reduced by 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com