Method for preparing nickel-containing methanation catalyst quickly

A nickel methanation and catalyst technology, applied in the field of rapid preparation of nickel-containing methanation catalysts, can solve the problems of poor overall effect, long time, strict preparation process conditions, etc., and achieve product stability and anti-kink performance, data Informative and accurate, the effect of reasonable ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing:

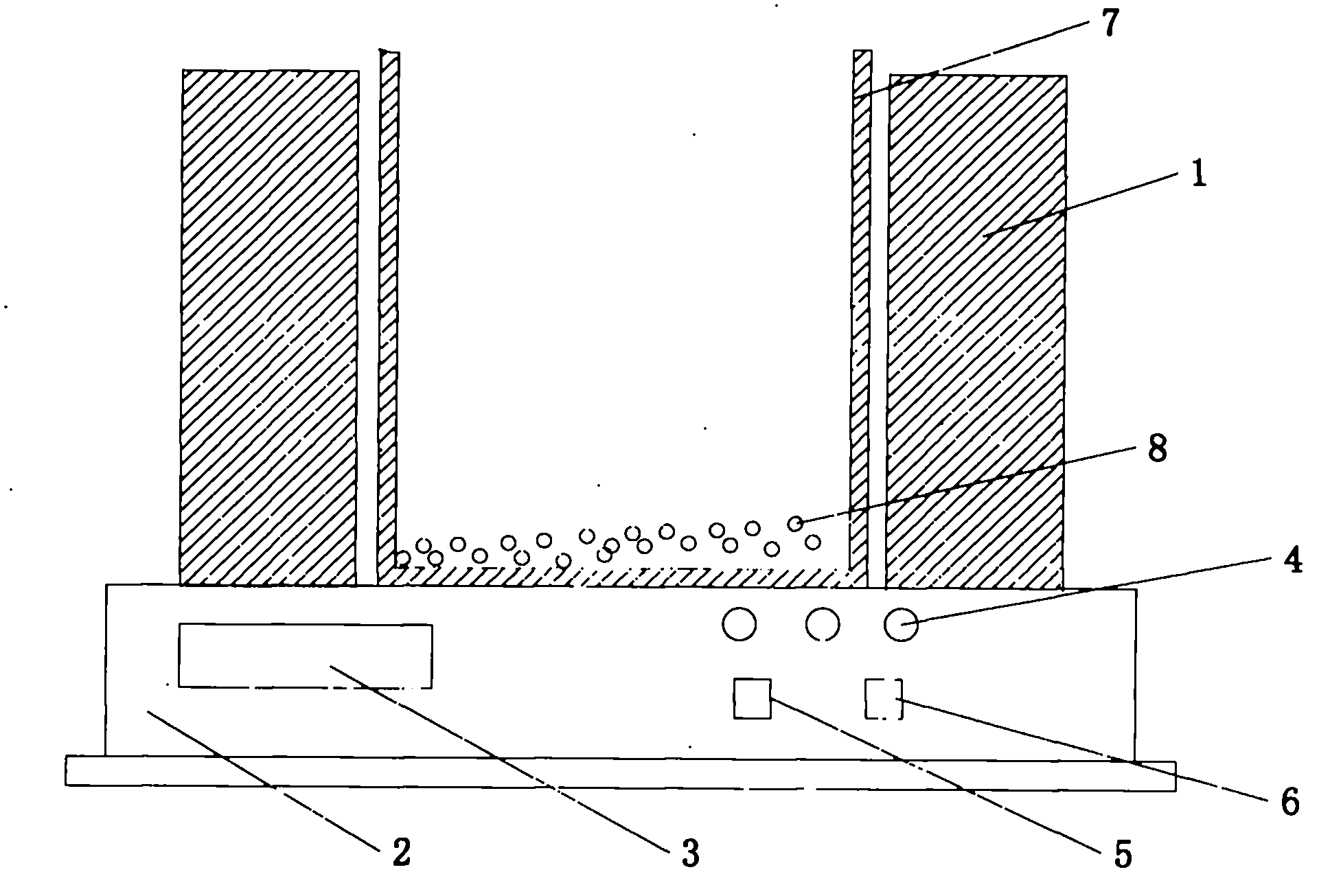

[0065] figure 1 As shown, in order to prepare the nitrate wet gel state diagram, it is necessary to operate in sequence according to the ratio.

[0066] Quantities of chemicals used in the preparation, determined according to pre-set ranges, in grams, milliliters, centimeters 3 is the unit of measurement.

[0067] The preparation of nitrate wet gel is carried out in the beaker 7, which is completed under heating. The beaker 7 is placed in the electric heating jacket 1. The inside of the beaker 7 is the wet gel 8, and the lower part of the electric heating jacket 1 is the electric control box. 2. The electric control box 2 is provided with a display screen 3 , an indicator light 4 , an electric thermostat 5 , and a power switch 6 .

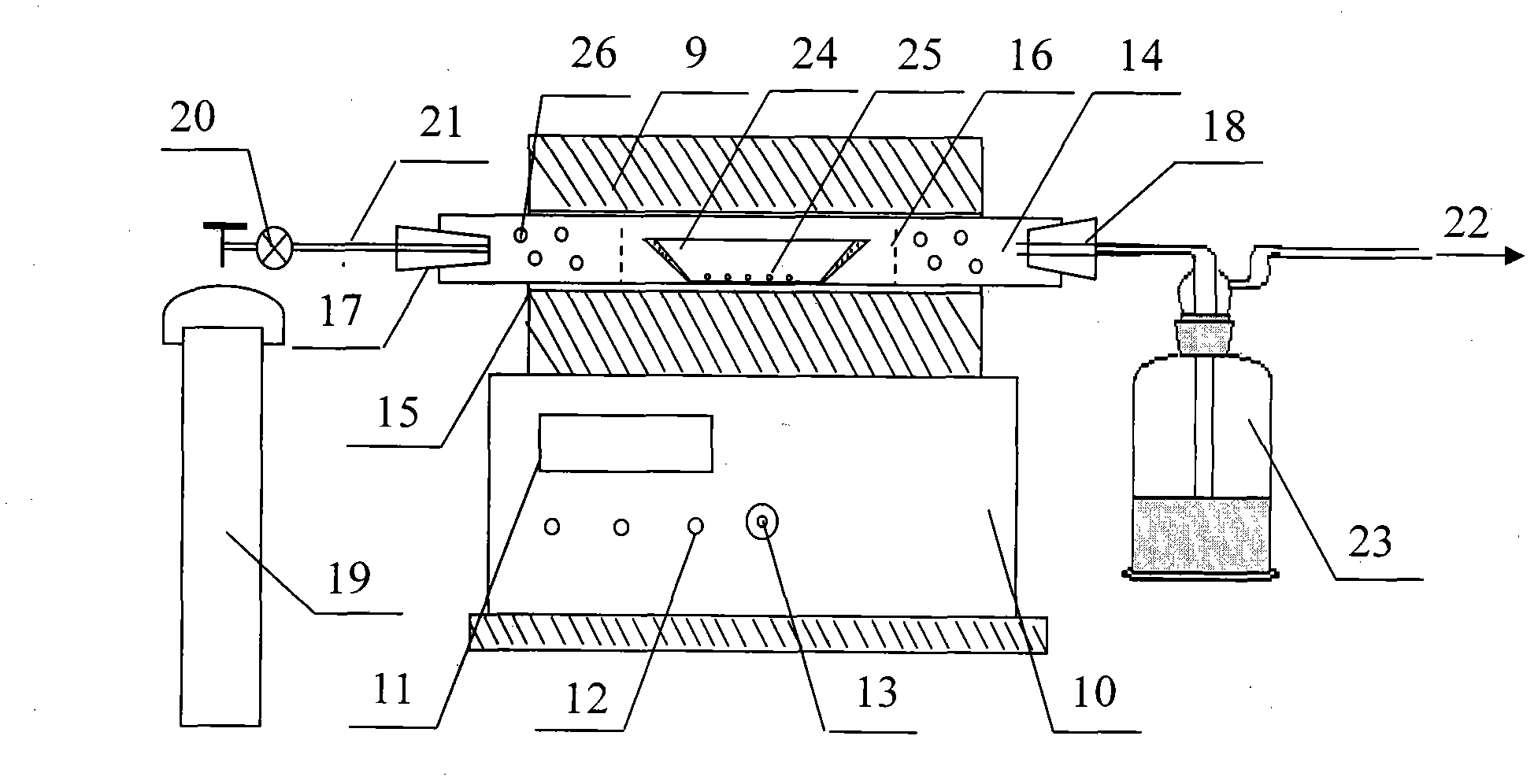

[0068] figure 2 As shown in the figure, the state diagram of the catalyst is prepared for the tubular high-temperature furnace. The positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com