Locked reticulate pattern UV (ultraviolet) printing method

A technology of locking screen and dots, applied in the field of locking screen UV printing and coating, can solve the problems of reducing the printing suitability of products, large dot expansion rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using the locking screen pattern UV printing and coating technology of the present invention to make a milk powder can for ordinary packaging of 3 sections as an example, the hardness of the tinplate is T4, the amount of tin plating is 2.8 / 2.8, and the specification of the iron sheet is 0.23*802*7300, which includes the following steps:

[0034] 1) Locked texture data information processing

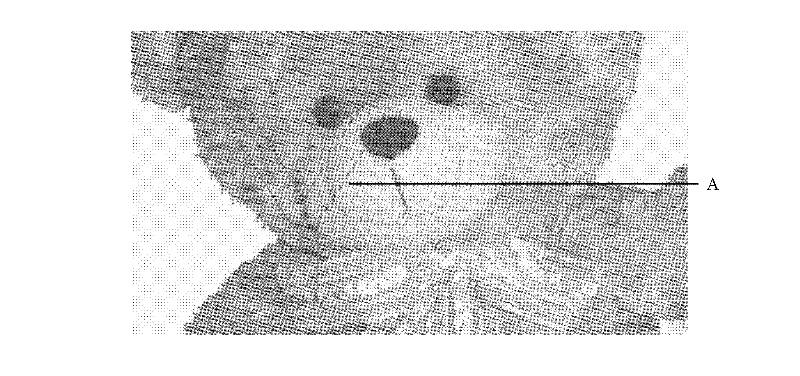

[0035] Analyze the level distribution and color tone data of graphic data files, select the appropriate locking area A, and generally select the midtone area with rich color tone levels; see figure 1 , figure 2 ;

[0036] Use the professional drawing software module Power Lock to draw the locked graphics in the locked area (the locked graphics can be personalized according to customer requirements, such as using customer LOGO), and make the locked graphics into an independent vector file;

[0037] Select the appropriate channel to lock the graphics that need to be locked. Genera...

Embodiment 2

[0051] Using the lock screen pattern UV printing and coating technology of the present invention to make a beverage can as an example, the hardness of the tinplate is T4, the amount of tin plating is 1.1 / 2.8, and the specification of the iron sheet is 0.20*860*1036, which includes the following steps:

[0052] 1) Locked texture data information processing

[0053] Carry out layer distribution and color tone data analysis on graphic data files, select the appropriate locking area, generally choose the middle tone area with rich color tone layers;

[0054] Use the professional drawing software module Power Lock to draw the locked graphics in the locked area (the locked graphics can be personalized according to customer requirements, such as using customer LOGO), and make the locked graphics into an independent vector file;

[0055] Select the appropriate channel to lock the graphics that need to be locked. Generally, choose a channel with a relatively high layer coverage, such as ...

Embodiment 3

[0069] Using the lock screen pattern UV printing and coating technology of the present invention to make a certain eight-treasure porridge can as an example, the hardness of the tinplate is T4, the amount of tin plating is 1.1 / 1.1, and the specification of the iron sheet is 0.20*884*1036, which includes the following steps:

[0070] 1) Locked texture data information processing

[0071] Carry out layer distribution and color tone data analysis on graphic data files, select the appropriate locking area, generally choose the middle tone area with rich color tone layers;

[0072] Use the professional drawing software module Power Lock to draw the locked graphics in the locked area, and make the locked graphics into independent vector files;

[0073] Select the appropriate channel to lock the graphics that need to be locked. Generally, choose a channel with a relatively high layer coverage, such as a blue or red channel; select the locked graphics in the selected locking channel t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Coating amount | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com