Method for preparing ZSM-5 zeolite molecular sieve microspheres

A kind of technology of zeolite molecular sieve, ZSM-5

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

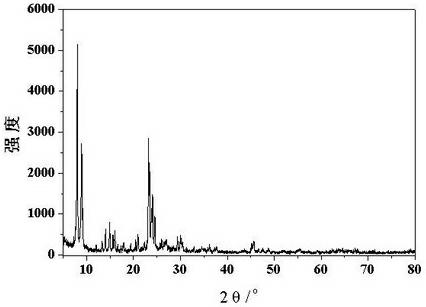

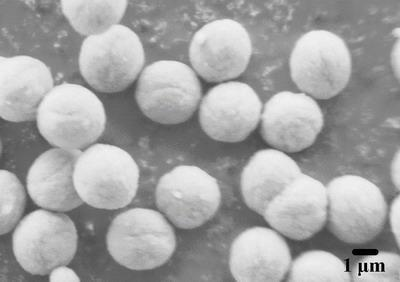

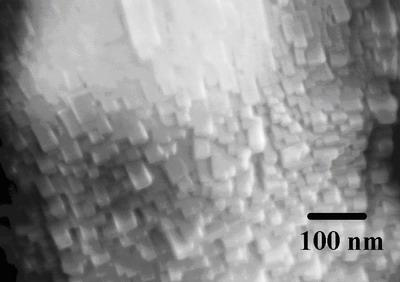

[0022] Take 1.5 ml of polymethylsiloxane and disperse it in 15 ml of absolute ethanol and stir evenly to obtain solution I for later use; weigh 0.02 g of NaAlO 2 Dissolve 0.06g NaOH in 35ml of distilled water, then add 19ml of tetrapropylammonium hydroxide 25% aqueous solution, stir evenly, add 6ml of tetraethyl orthosilicate dropwise, stir at room temperature for 3 hours to obtain a transparent solution, then add 12ml of solution I, After stirring at room temperature for 5 hours, a translucent solution was obtained. The product was transferred to a closed reaction kettle, and after crystallization at 90°C for 4 days, the reaction kettle was taken out to cool naturally. Vacuum drying for 36 hours, followed by calcination in a muffle furnace at 400°C for 5 hours to obtain ZSM-5 zeolite molecular sieve microspheres.

Embodiment 2

[0024] Take 2.5 ml of polymethylsiloxane and disperse it in 24ml of n-propanol and stir it evenly to obtain solution I for later use; weigh 0.08g of NaAlO 2 Dissolve 0.12g NaOH in 75ml of distilled water, then add 17ml of n-butylamine, stir evenly, add dropwise 10ml of tetraethyl orthosilicate, stir at room temperature for 6 hours to obtain a transparent solution, then add 20ml of solution I, and stir at room temperature for 12 hours to obtain half Transparent solution, transfer the product into a closed reaction kettle, crystallize at 180°C for 5 days, take out the reaction kettle to cool naturally, separate the product in the kettle, wash with ethanol for 3 times, wash with water twice, vacuum dry at 50°C for 24h, and dry at 600°C ℃ in a muffle furnace for 5 h to obtain ZSM-5 zeolite molecular sieve microspheres.

Embodiment 3

[0026] Disperse 4.5 ml of methyltriethoxysilane in 35 ml of ethanol and stir to obtain solution I for later use; weigh 0.10 g of NaAlO 2 Dissolve 0.28g NaOH in 155ml distilled water, then add 40ml tetrapropylammonium hydroxide 25% aqueous solution, stir evenly, add 14ml tetraethyl orthosilicate dropwise, stir at room temperature for 9 hours to obtain a transparent solution, then add 16ml solution I, After stirring at room temperature for 24 hours, a translucent solution was obtained. The product was transferred into a closed reaction kettle, and after crystallization at 150°C for 7 days, the reaction kettle was taken out to cool naturally, and the product in the kettle was separated, washed with ethanol for 3 times, then washed with water twice, and vacuumed at 60°C. Dry for 12 hours, and bake in a muffle furnace at 550° C. for 7 hours to obtain ZSM-5 zeolite molecular sieve microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com